Rear Hub Shafts

26 posts

• Page 1 of 2 • 1, 2

Quick one...

I've bought a set of inner and outer drive shafts from TTR and will be fitting them this summer, so a few questions...

1) It says to lap in with valve gringing paste, ok no big deal with that, BUT its years since I've used engineers blue... so how do you apply it to the shaft? Completley cover it and see what wipes off or put a sterak down the taper and see how it distributes?? What king of trace should I be looking for?

2) The hub nuts supplied are not nyloc, however the last 1/8" of the thread (on both nuts) is very tight, seems to be peened over a tad. Further they look to be bigger thread than the standard nuts. SO are they a "special" nut or should I get an equivalent size nyloc?

thanks in advance...

Mark

I've bought a set of inner and outer drive shafts from TTR and will be fitting them this summer, so a few questions...

1) It says to lap in with valve gringing paste, ok no big deal with that, BUT its years since I've used engineers blue... so how do you apply it to the shaft? Completley cover it and see what wipes off or put a sterak down the taper and see how it distributes?? What king of trace should I be looking for?

2) The hub nuts supplied are not nyloc, however the last 1/8" of the thread (on both nuts) is very tight, seems to be peened over a tad. Further they look to be bigger thread than the standard nuts. SO are they a "special" nut or should I get an equivalent size nyloc?

thanks in advance...

Mark

-

mark030358 - Coveted Fifth Gear

- Posts: 1182

- Joined: 29 May 2004

Hello Mark,

I have read (in here) that TTR hub shafts have dispensed with the keyway? Is that the case? If so then, presumably, subsequent removal & replacement wouldn't necessarily keep hub & shaft in the same angular orientation?

It's a long time ago for me too. However, on this, and other assemblies, I have lightly covered the contact area with the blue first, not used the parts to distribute it.

Lapping has been discussed on here quite a lot: e.g...

elan-archive-f16/rear-drive-tapered-hubs-t6419.html

...where a target contact area is given. (In addition, other threads have warnings not to overdo it such that the hub goes on too far)

Re: Hub nuts. They sound like a form of "Stover Nut" or similar. Not something I would use for that application. Maybe removal isn't anticipated? (Some cars, today, have them on manifolds studs, and BOTH nuts & studs have to replaced after a while when the interference fit is reduced)

HIH

Cheers - Richard

I have read (in here) that TTR hub shafts have dispensed with the keyway? Is that the case? If so then, presumably, subsequent removal & replacement wouldn't necessarily keep hub & shaft in the same angular orientation?

It's a long time ago for me too. However, on this, and other assemblies, I have lightly covered the contact area with the blue first, not used the parts to distribute it.

Lapping has been discussed on here quite a lot: e.g...

elan-archive-f16/rear-drive-tapered-hubs-t6419.html

...where a target contact area is given. (In addition, other threads have warnings not to overdo it such that the hub goes on too far)

Re: Hub nuts. They sound like a form of "Stover Nut" or similar. Not something I would use for that application. Maybe removal isn't anticipated? (Some cars, today, have them on manifolds studs, and BOTH nuts & studs have to replaced after a while when the interference fit is reduced)

HIH

Cheers - Richard

- ardee_selby

- Coveted Fifth Gear

- Posts: 2197

- Joined: 30 Sep 2003

rgh0 wrote:TTR will supply hubs both with or without the keyway to your preference. i got a rear hub a few weeks ago with the keyway. cheers Rohan

I am confused as to what benefit there is to having a keyway and pin. Seems to me the keyway just adds a point of stress (ref: Dave Bean and others advice on relieving an area of the shaft)

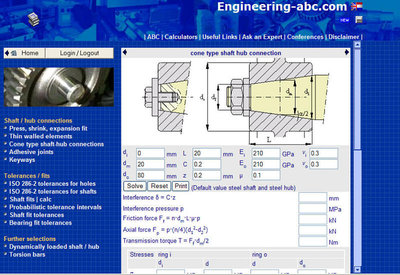

Found this tool on-line though...

... at: http://www.tribology-abc.com/sub23.htm

It LOOKS good. Wish I understood how to apply it

Cheers - Richard

- ardee_selby

- Coveted Fifth Gear

- Posts: 2197

- Joined: 30 Sep 2003

Technically you dont need the keyway. The hub will lock on the shaft purely under the hub nut compression.

If it does not lock due to inadequate compression e.g. if the nut and washer bottom out on the end of the shaft first then it will shear the key ( been there done that)

Why Lotus felt the need for a key I dont know but I am sure they had a reason so I will leave it until I understand why and thus understand fully why removing it is OK.

cheers

Rohan

( a sometime mech eng)

If it does not lock due to inadequate compression e.g. if the nut and washer bottom out on the end of the shaft first then it will shear the key ( been there done that)

Why Lotus felt the need for a key I dont know but I am sure they had a reason so I will leave it until I understand why and thus understand fully why removing it is OK.

cheers

Rohan

( a sometime mech eng)

-

rgh0 - Coveted Fifth Gear

- Posts: 8831

- Joined: 22 Sep 2003

Thanks for the replies..

Stover nuts never heard of them ???? So if I buy some nylocs is there a grade to buy??

Anybody else outhere fitted the TTR drive shafts? did you use the nuts he supplies??

Thanks

Stover nuts never heard of them ???? So if I buy some nylocs is there a grade to buy??

Anybody else outhere fitted the TTR drive shafts? did you use the nuts he supplies??

Thanks

-

mark030358 - Coveted Fifth Gear

- Posts: 1182

- Joined: 29 May 2004

Mark,

I have just put a set on my S4. The thread is indeed larger than the original, possibly for race applications? I was a little hesitant at using the nuts supplied, as I thought they might damage the thread as they were tightened up. But then, why would TTR supply nuts that would cause the part to be unservicable next time the nut was removed? So, went ahead and used them without any problems.

A proper "stover" nut has been crimped at the end and is forced back toward it's original shape as it is tightened up. This added friction stops the nut from becoming loose,but can damage the thread.

The TTR nut is quite different. It has been cut diagonally from both sides, at the end, and then the ends pressed down to reduce the diameter of the nut's internal dimension. As the nut is tightened, the ends are spread apart and grip the thread. Because of the diagonal cuts, the ends spread more easily than a stover nut and and the thread is not damaged.

Cheers,

Colin.

I have just put a set on my S4. The thread is indeed larger than the original, possibly for race applications? I was a little hesitant at using the nuts supplied, as I thought they might damage the thread as they were tightened up. But then, why would TTR supply nuts that would cause the part to be unservicable next time the nut was removed? So, went ahead and used them without any problems.

A proper "stover" nut has been crimped at the end and is forced back toward it's original shape as it is tightened up. This added friction stops the nut from becoming loose,but can damage the thread.

The TTR nut is quite different. It has been cut diagonally from both sides, at the end, and then the ends pressed down to reduce the diameter of the nut's internal dimension. As the nut is tightened, the ends are spread apart and grip the thread. Because of the diagonal cuts, the ends spread more easily than a stover nut and and the thread is not damaged.

Cheers,

Colin.

mark030358 wrote:Thanks for the replies..

Stover nuts never heard of them ???? So if I buy some nylocs is there a grade to buy??

Anybody else outhere fitted the TTR drive shafts? did you use the nuts he supplies??

Thanks

'68 S4 DHC

- fatboyoz

- Fourth Gear

- Posts: 693

- Joined: 04 Oct 2003

Yes, as I reported at the time, TT persuaded me to replace my perfectly serviceable hub shafts with his keyless ones. Despite scrupulous fitting, one failed. TT, of course told me it was because I was an idiot, such a charmer. He then recommended torqueing up the hub nuts every (!) time I use the car.

Keyway drilled and key fitted = no more problems.

Jim

Keyway drilled and key fitted = no more problems.

Jim

- jimj

- Coveted Fifth Gear

- Posts: 1119

- Joined: 25 Feb 2008

Thanks for the answers, out of interest I bought the ones with a key way.

But going back to engineers blue issue, what trace pattern should I look for after lapping in?

thanks

But going back to engineers blue issue, what trace pattern should I look for after lapping in?

thanks

-

mark030358 - Coveted Fifth Gear

- Posts: 1182

- Joined: 29 May 2004

I usually get the moron award on this forum. I got a pair of TT hubs and drive axles 15 years ago to install on my S2 that was going to cope with a 1700cc 150 hp twin cam. I got it all through Ray at RD ent and there were no instructions or other info. I looked at them and thought they looked pretty nice. So when it was finally time to install them, This moron did and the only problem I had was getting enough torque on them, when I pulled up I lifted the back of the elan and when I pushed down, the Elan rolled forward. Some how this DMF must have got it close because they have been on for 15 years and the only issue that I have had it the reddish-orange patina that has developed. They do have the key but I figure thats just about as useless as ToaB. I think I just maxed out the 200ft/lb torque wrench or just used an 18 inch breaker-bar and gave till I burst a blood vessel, what ever I did, I thought that was good enough and it apparently has been.

Gary

http://www.engineershandbook.com/Tables/torque2.htm

Gary

http://www.engineershandbook.com/Tables/torque2.htm

-

garyeanderson - Coveted Fifth Gear

- Posts: 3391

- Joined: 12 Sep 2003

Mark,

I'm sure Gary has uploaded photos of his lapped shaft(s) & hubs(s) somewhere, but I can't locate them at the moment...

However, have a look at this link. A different application but same process involved here:

http://www.mastercraft.com/teamtalk/sho ... hp?t=29565

Hope it helps

Cheers - Richard

I'm sure Gary has uploaded photos of his lapped shaft(s) & hubs(s) somewhere, but I can't locate them at the moment...

However, have a look at this link. A different application but same process involved here:

http://www.mastercraft.com/teamtalk/sho ... hp?t=29565

Hope it helps

Cheers - Richard

- ardee_selby

- Coveted Fifth Gear

- Posts: 2197

- Joined: 30 Sep 2003

ardee_selby wrote:Mark,

I'm sure Gary has uploaded photos of his lapped shaft(s) & hubs(s) somewhere, but I can't locate them at the moment...

However, have a look at this link. A different application but same process involved here:

http://www.mastercraft.com/teamtalk/sho ... hp?t=29565

Hope it helps

Cheers - Richard

Maybe this topic in the plus2 area

elan-plus-f13/replacing-right-rear-hub-key-t21071-15.html

Gary

p.s. - I didn't use any bluing - just my bad eyes

-

garyeanderson - Coveted Fifth Gear

- Posts: 3391

- Joined: 12 Sep 2003

Spread the blue over the shaft taper evenly and very very thinly

The fit the hub without torquing it up and remove it again. I lightly tap the hub in place with a hammer and taper it again to remove it.

This will transfer blue from the shaft taper to the hub taper

Look for areas on the hub where the blue does not tranfer

If you get a nice even transfer over the whole surface then the hub and shaft are fitting well.

It is hard to get the blue on the axle taper thin enough sometimes so I woiuld check a second time by not putting any more blue on the axle taper and cleaning just the hub taper and fitting it again and remove it and check again.

cheers

Rohan

The fit the hub without torquing it up and remove it again. I lightly tap the hub in place with a hammer and taper it again to remove it.

This will transfer blue from the shaft taper to the hub taper

Look for areas on the hub where the blue does not tranfer

If you get a nice even transfer over the whole surface then the hub and shaft are fitting well.

It is hard to get the blue on the axle taper thin enough sometimes so I woiuld check a second time by not putting any more blue on the axle taper and cleaning just the hub taper and fitting it again and remove it and check again.

cheers

Rohan

-

rgh0 - Coveted Fifth Gear

- Posts: 8831

- Joined: 22 Sep 2003

Thanks for all the comments most appreciated.

The pictures were a boon.

Been almost 38 years since I put enginers blue on anything (as a first year apprentice... WoW getting old

The pictures were a boon.

Been almost 38 years since I put enginers blue on anything (as a first year apprentice... WoW getting old

-

mark030358 - Coveted Fifth Gear

- Posts: 1182

- Joined: 29 May 2004

Update...

Blued up the TTR shafts with new TTR rear hubs and I guess an 85% coverage... seems ok to me straight out of the box so to speak

cheers

Blued up the TTR shafts with new TTR rear hubs and I guess an 85% coverage... seems ok to me straight out of the box so to speak

cheers

-

mark030358 - Coveted Fifth Gear

- Posts: 1182

- Joined: 29 May 2004

26 posts

• Page 1 of 2 • 1, 2

Total Online:

Users browsing this forum: No registered users and 17 guests