Cosworth YB Turbo Into Elan

Front section of mould made, just needs to cure. What do you think of my ultra lightweight grill?

- stevebroad

- Fourth Gear

- Posts: 917

- Joined: 08 Mar 2004

Decided to add some aero to the front wings:

Actually, the lip of the front arches rolled under and would be a pain to replicate so decided to have a knife edge. This required a slight widening of the arch to look right, IMO. The upright plastic is just there to allow the mould to turn up so making the edge of the mould stiffer. The final wing width will be back from this, decided once bonnet and wheels are fitted.

Actually, the lip of the front arches rolled under and would be a pain to replicate so decided to have a knife edge. This required a slight widening of the arch to look right, IMO. The upright plastic is just there to allow the mould to turn up so making the edge of the mould stiffer. The final wing width will be back from this, decided once bonnet and wheels are fitted.

- stevebroad

- Fourth Gear

- Posts: 917

- Joined: 08 Mar 2004

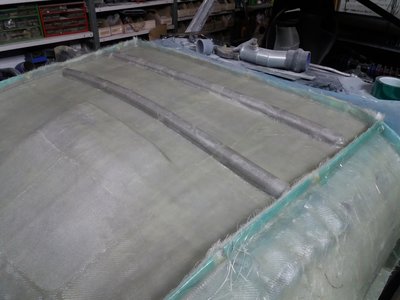

Wing moulds now done. Just the bonnet area to do (the biggest but easiest part).

- stevebroad

- Fourth Gear

- Posts: 917

- Joined: 08 Mar 2004

nmauduit wrote:nice work. Are you planning a frame of some sort to hold the parts together like a jig, or would you mould directly when bolted together (what thickness is the mould)?

Thanks.

The plan is to drill and bolt the sections of mould together. A support will be placed between the bottom of the wings once it is bagged up in order to resist any warping. However the materials used have been designed to withstand the proposed 120 deg C temp. I have added a 30mm lip all the way round the mould to add to the stiffness.

The mould is made from a layer of gel coat followed by one layer of 100gm woven glass mat and 6 layers of 210gm woven glass mat. The wing vents were covered in an epoxy moulding paste prior to the glass fibre.

- stevebroad

- Fourth Gear

- Posts: 917

- Joined: 08 Mar 2004

Run out of high temp resin so still a couple of layers of fibreglass to be added to the bonnet area but I am almost there. Should be ready to attempt to remove the mould by Thursday.

- stevebroad

- Fourth Gear

- Posts: 917

- Joined: 08 Mar 2004

Mould removed and just fitted into my oven  Just awaiting the prepreg carbon.

Just awaiting the prepreg carbon.

- stevebroad

- Fourth Gear

- Posts: 917

- Joined: 08 Mar 2004

Just amazing work Steve.

Glen

05 Elise - Back where I started

65 Elan S2 - 26/4055

72 Europa - 74/2358R

69 Elan S4 - 45/7941

64 Elan S1 - 26/0379

12 Colin 30 - Lotus Racing Kart

07 Exige S - Wicked Road/Track Car

07 Exige S - Fast Road/Track Car

06 Elise - Track pack

05 Elise - Back where I started

65 Elan S2 - 26/4055

72 Europa - 74/2358R

69 Elan S4 - 45/7941

64 Elan S1 - 26/0379

12 Colin 30 - Lotus Racing Kart

07 Exige S - Wicked Road/Track Car

07 Exige S - Fast Road/Track Car

06 Elise - Track pack

-

Certified Lotus - Coveted Fifth Gear

- Posts: 1233

- Joined: 04 Aug 2014

Certified Lotus wrote:Just amazing work Steve.

Hi Glen.

Thanks. It is still a steep learning curve but I haven't fallen back down the slope yet

Steve

- stevebroad

- Fourth Gear

- Posts: 917

- Joined: 08 Mar 2004

nmauduit wrote:Did you use epoxy for the mould for better standing the curing, and what temperature are you planning to cure?

superbe work, looking forward to see the outcome...

taking the time to post is really empowering, thank you!

Thanks.

The epoxy gelcoat is used to give a much smoother surface than by just using fibreglass. The gelcoat and fibreglass expoxies are designed to deal with the elevated oven temps as normal fibreglass resin starts to break down over 90 deg C.

The plan is to cure at 120 deg C which will take around one hour. However it takes a while to get to this figure as I can only increase the temp by a maximum 3 deg C per minute. This is to ensure that the mould and carbon both increase in temp at a controlled and similar rate.

Once cured it is left to cool naturally before demoulding.

- stevebroad

- Fourth Gear

- Posts: 917

- Joined: 08 Mar 2004

Total Online:

Users browsing this forum: No registered users and 13 guests