Fuel Pump Options?

17 posts

• Page 1 of 2 • 1, 2

The only thing I had not checked was the fuel pump!

Naturally it leaks like a sieve when left overnight after I had spun the engine to fill the fuel line.

Sadly the usual suspects had saved a few pence by fitting a pump without the female unf (?) threads. Instead they fitted - http://www.ptz.si/en/fuel-pumps/mechani ... s/pn-3261#

The gasket was distorted and the filter had a hole in it. Sadly I cannot find how or where to get spares. The factory in Slovenia is a bit of a trek. Or if there is a distributor in the UK.

A feeble slip on pipe with hose clips is hardly ideal to put next top the distributor, even by their standards.

So now, if I get a new pump I will need some adapters. 1/2 unf to straight pipe?

Anyone got an original pipe that fits an original style pump? And / or a good pump for sale?

I'm walking away for a day or so or there may be another +2 kit car.

Perhaps now is the time to consider an electric option?

Naturally it leaks like a sieve when left overnight after I had spun the engine to fill the fuel line.

Sadly the usual suspects had saved a few pence by fitting a pump without the female unf (?) threads. Instead they fitted - http://www.ptz.si/en/fuel-pumps/mechani ... s/pn-3261#

The gasket was distorted and the filter had a hole in it. Sadly I cannot find how or where to get spares. The factory in Slovenia is a bit of a trek. Or if there is a distributor in the UK.

A feeble slip on pipe with hose clips is hardly ideal to put next top the distributor, even by their standards.

So now, if I get a new pump I will need some adapters. 1/2 unf to straight pipe?

Anyone got an original pipe that fits an original style pump? And / or a good pump for sale?

I'm walking away for a day or so or there may be another +2 kit car.

Perhaps now is the time to consider an electric option?

- vincereynard

- Coveted Fifth Gear

- Posts: 1240

- Joined: 12 Jan 2015

Doesn`t it need to be flexible hoses to the pump. Did you intend to pipe it up in solid tubing?

The engine moves on its mountings and the carburettors are usually flexibly mounted on the head.

Maybe I have not understood your intentions properly.

Eric in Burnley

1967 S3SE DHC

The engine moves on its mountings and the carburettors are usually flexibly mounted on the head.

Maybe I have not understood your intentions properly.

Eric in Burnley

1967 S3SE DHC

- ericbushby

- Coveted Fifth Gear

- Posts: 1363

- Joined: 13 Jun 2011

Why do you consider push on with clip unsuitable, the pump has negative pressure on one side and a maximum of about 6 psi on the other, agreed the exact size pipe is required but it?s a perfectly good method.

Consider, how are the connections made to the carburettors, just that, push on rubber pipe with a clip. It may look different as there is a banjo fitment but it the same sealing method onto that fitment.

Consider, how are the connections made to the carburettors, just that, push on rubber pipe with a clip. It may look different as there is a banjo fitment but it the same sealing method onto that fitment.

- Craven

- Coveted Fifth Gear

- Posts: 1634

- Joined: 14 Sep 2013

I always thought that the correct pipe installation on a standard pump was for the black nylon pipe from the tank to be fitted with a suitable size olive/nut and screwed directly into the pump. The output side then needs a short length of metal tube again fitted with an olive/nut. Braided rubber pipe from here to the carb with jubilee clips.

- William2

- Fourth Gear

- Posts: 983

- Joined: 20 Jan 2013

Craven wrote:Why do you consider push on with clip unsuitable, the pump has negative pressure on one side and a maximum of about 6 psi on the other, agreed the exact size pipe is required but it?s a perfectly good method.

Consider, how are the connections made to the carburettors, just that, push on rubber pipe with a clip. It may look different as there is a banjo fitment but it the same sealing method onto that fitment.

It still requires a care and skill that has been sadly lacking so far.

The end of the pipe is distorted so it's unlikely to make a good fuel proof join. Also it seems counterintuitive to me to clam down on the stainless braided hose. It resists compression.

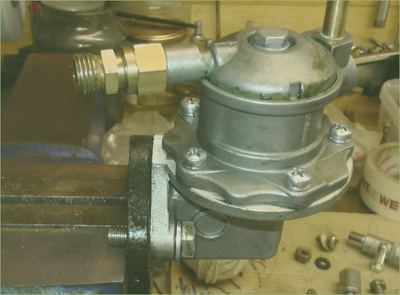

Slipping the end cover off showed quite what a mess it was.

However things have moved on since then . I have been in touch with the makers in Slovakia and they stated -

"You mean it leaks on the top? Did you open the pump or change cover

position?

If you did it, than you need to change washer and use some glue on both

sides, or you won't be able to seal it by hand."

Now it is more than likely the restorers, to use the term loosely, shifted the top to get it to fit. Not knowing, or likely considering, that it would not seal properly again.

Could this be the reason for the constant petrol stink in the garage? A slow weep out of the pump that quickly evaporates?

It nitrile rubber fuel proof? I could make up two thin gaskets with a filter mess in between them.

As stated above there is little actual pressure. Probably at maximum when the car is standing with a full tank. Atmospheric pressure rises 1/10th of a bar per metre. The tank has a head of 600mm (?). Not much.

Or is this nonsense?

- vincereynard

- Coveted Fifth Gear

- Posts: 1240

- Joined: 12 Jan 2015

You do have an uphill battle, If you are still considering changing to rigid pipe connection to the pump make sure the pump you have is machined inside to accept the olives. The pump shown in you link has screwed in hose tails so may not be suitable.

With push on connectors the pipe I/D must be exactly the corresponding size for the hose tail, the seal is NOT made by the tightness of the clip but between the expanded end of the tail and the slight expansion of the hose over it. May come as a surprise to many but the clip is just to stop the hose coming off. If you have a leak from any of this type of connection it?s not from a loose clip.

FWIW

Ron.

With push on connectors the pipe I/D must be exactly the corresponding size for the hose tail, the seal is NOT made by the tightness of the clip but between the expanded end of the tail and the slight expansion of the hose over it. May come as a surprise to many but the clip is just to stop the hose coming off. If you have a leak from any of this type of connection it?s not from a loose clip.

FWIW

Ron.

- Craven

- Coveted Fifth Gear

- Posts: 1634

- Joined: 14 Sep 2013

vincereynard wrote:

It nitrile rubber fuel proof? I could make up two thin gaskets with a filter mess in between them.

As stated above there is little actual pressure. Probably at maximum when the car is standing with a full tank. Atmospheric pressure rises 1/10th of a bar per metre. The tank has a head of 600mm (?). Not much.

nitrile is fuel proof, it comes in different hardness varieties but in general is not as flexible as cork, so if you have a serious alloy body/cover distortion it may not be a suitable fix alone... stock bowl pumps, which are rebuildable, have a cork/nitrile gasket I believe, and it is not glued, just held by the bolt which is tightened by hand above the glass bowl. If you trap something between 2 gasket you'll have a hard time to avoid leaks, esp. nitrile : on stock pumps there is a brass gauze filter inside the cavity, snug onto the fuel port to the carbs.

as for the steel braided hoses, I believe that proper fittings tighten the inside hose and the outside steel separately (not always easy to slip them correctly) : from glancing at your photo, you may want to check if you can slip the steel in between the jubilee and the body of the fitting (slotting the steel if required, yet the steel should go deep enough so as to be held when everything is tight).

S4SE 36/8198

-

nmauduit - Coveted Fifth Gear

- Posts: 2045

- Joined: 02 Sep 2013

Craven wrote:With push on connectors the pipe I/D must be exactly the corresponding size for the hose tail, the seal is NOT made by the tightness of the clip but between the expanded end of the tail and the slight expansion of the hose over it. May come as a surprise to many but the clip is just to stop the hose coming off. If you have a leak from any of this type of connection it?s not from a loose clip.

FWIW

Ron.

So what you are saying is the steel braiding, being reluctant to compress or expand, is there to prevent the hose expanding and therefore making a tighter join. Interesting.

nmauduit wrote:as for the steel braided hoses, I believe that proper fittings tighten the inside hose and the outside steel separately (not always easy to slip them correctly) : from glancing at your photo, you may want to check if you can slip the steel in between the jubilee and the body of the fitting (slotting the steel if required, yet the steel should go deep enough so as to be held when everything is tight).

I've stripped back the tatty steel bits so that the hose clip acts on the pipe itself.

I cut a sealing gasket out of 2mm nitrile rubber and added a small O ring to the underneath of the fixing bolt. (Otherwise it will leak past the bolt!) So far it has held 10 psi air pressure overnight so that is encouraging. Now to make up a suitable brass filter and try again.

Sorry rubbish image -

- vincereynard

- Coveted Fifth Gear

- Posts: 1240

- Joined: 12 Jan 2015

There are at least two types of braided hose, where the braid has different functions.

In the type of hose you show the braid provides protection against abrasion etc and is loosely bound this type has a certain ? give ? and within reason suitable for push on connectors.

Another type of hose has a tightly bound braiding, an example would be flexible brake hose where its purpose is to stop the inner hose expanding, greatly increasing its pressure rating, this type of hose is unusable for push on connection.

In the type of hose you show the braid provides protection against abrasion etc and is loosely bound this type has a certain ? give ? and within reason suitable for push on connectors.

Another type of hose has a tightly bound braiding, an example would be flexible brake hose where its purpose is to stop the inner hose expanding, greatly increasing its pressure rating, this type of hose is unusable for push on connection.

- Craven

- Coveted Fifth Gear

- Posts: 1634

- Joined: 14 Sep 2013

vincereynard wrote:I cut a sealing gasket out of 2mm nitrile rubber and added a small O ring to the underneath of the fixing bolt. (Otherwise it will leak past the bolt!) So far it has held 10 psi air pressure overnight so that is encouraging. Now to make up a suitable brass filter and try again.

10 PSI should be plenty safety margin, regular operation usually being around 2-4 ...

S4SE 36/8198

-

nmauduit - Coveted Fifth Gear

- Posts: 2045

- Joined: 02 Sep 2013

First - the good news.

I have received a small envelope of spares washers and filters as a freebie from the manufacturers in Slovakia! Jolly decent of them.

I'll fit the bits and pressure test again.

Now back to Arachnid SNAFU. Surely the attachment bolts are too short. (And that's with the spring washer replaced with a plain.)

I'm going to replace them with studding to make fitting the pump at lot easier. (It was a pig last time.)

As I've been saying for the last month - nearly there!

I have received a small envelope of spares washers and filters as a freebie from the manufacturers in Slovakia! Jolly decent of them.

I'll fit the bits and pressure test again.

Now back to Arachnid SNAFU. Surely the attachment bolts are too short. (And that's with the spring washer replaced with a plain.)

I'm going to replace them with studding to make fitting the pump at lot easier. (It was a pig last time.)

As I've been saying for the last month - nearly there!

- vincereynard

- Coveted Fifth Gear

- Posts: 1240

- Joined: 12 Jan 2015

When fitting the Pump i have found it is easier if you turn the Engine over by hand to position the Fuel Pump cam in it's lowest position. Then fitting the Pump you are not pushing against the Pump action on the Cam profile.

If you fit a Pump (without a glass dome)all metal then check the output pressure it is producing.

I have found the all metal Pumps tend to produce too much pressure for the Webers or Dellortos. Therefore a Fuel pressure Regulater is needed.

Alan

If you fit a Pump (without a glass dome)all metal then check the output pressure it is producing.

I have found the all metal Pumps tend to produce too much pressure for the Webers or Dellortos. Therefore a Fuel pressure Regulater is needed.

Alan

Alan.b Brittany 1972 elan sprint fhc Lagoon Blue 0460E

- alan.barker

- Coveted Fifth Gear

- Posts: 3711

- Joined: 06 Dec 2008

Could one of you please tell me the fuel pressure our Webers expect to see?

What pressure was designed into the stock Elan mechanical pump?

I'm planning to install an electric pump and may need to regulate the pressure.

What pressure was designed into the stock Elan mechanical pump?

I'm planning to install an electric pump and may need to regulate the pressure.

- TurbineHeli

- Second Gear

- Posts: 64

- Joined: 24 Nov 2012

TurbineHeli wrote:Could one of you please tell me the fuel pressure our Webers expect to see?

What pressure was designed into the stock Elan mechanical pump?

I'm planning to install an electric pump and may need to regulate the pressure.

Webers like about 2 to 2-1/2 psig.

There is no cure for Lotus, only treatment.

-

StressCraxx - Coveted Fifth Gear

- Posts: 1425

- Joined: 26 Sep 2003

Where did you get the pump from it's not as original.

Alan

Alan

Alan.b Brittany 1972 elan sprint fhc Lagoon Blue 0460E

- alan.barker

- Coveted Fifth Gear

- Posts: 3711

- Joined: 06 Dec 2008

17 posts

• Page 1 of 2 • 1, 2

Total Online:

Users browsing this forum: No registered users and 7 guests