Help - refitting clutch slave cylinder & clutch fork stuck

28 posts

• Page 1 of 2 • 1, 2

Hi All

I need your sage advise please. I am refitting the clutch slave cylinder and the clutch release fork is stuck towards the front of the car i.e. closest to the engine.

- I have tried to give it a push by hand but no movement (I get a few mills and thats it)

- I have tried to change gears in the car and it will go in and out of all gears (including reverse) with no problems

Whats the advice, as I have no clutch (the slave cylinder is off and there is no fluid) then I can't simply press/release the clutch.

Its on axle stands at the moment, do you think I will need to put it back on the floor - push it out of the garage, put it in gear and start the car - I read similar on a forum post.

Thanks

Gareth

I need your sage advise please. I am refitting the clutch slave cylinder and the clutch release fork is stuck towards the front of the car i.e. closest to the engine.

- I have tried to give it a push by hand but no movement (I get a few mills and thats it)

- I have tried to change gears in the car and it will go in and out of all gears (including reverse) with no problems

Whats the advice, as I have no clutch (the slave cylinder is off and there is no fluid) then I can't simply press/release the clutch.

Its on axle stands at the moment, do you think I will need to put it back on the floor - push it out of the garage, put it in gear and start the car - I read similar on a forum post.

Thanks

Gareth

To get something you've never had, you need to do something you've never done!

- GHill

- Second Gear

- Posts: 210

- Joined: 06 Sep 2014

As an update I wound the push rod nut all the way in (towards the clutch slave cylinder) and managed to fit and bleed (to an extent) the clutch.

My plan is to get a 20mm spanner (typically the one I don't have) and to then slowly tighten as much as possible and try to use the clutch itself to move the clutch release fork?

What do we think - should this work?

Regards

Gareth

My plan is to get a 20mm spanner (typically the one I don't have) and to then slowly tighten as much as possible and try to use the clutch itself to move the clutch release fork?

What do we think - should this work?

Regards

Gareth

To get something you've never had, you need to do something you've never done!

- GHill

- Second Gear

- Posts: 210

- Joined: 06 Sep 2014

Hi Gareth,

Seems an unusual situation, the clutch release fork is on a pivot therefore from your description the fork and release bearing are as far away from contact with the clutch as possible.

Normally with no cylinder fitted the fork, just using fingers, should slide the release bearing into contact with the clutch pressure plate ( fork toward the gearbox ) and away from the pressure plate ( fork toward the engine ) with from memory about 1 inch free play.

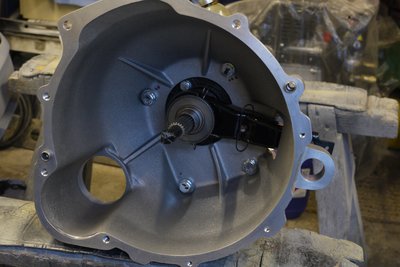

If you are not familiar with the arrangement this pic may help.

Ron.

Seems an unusual situation, the clutch release fork is on a pivot therefore from your description the fork and release bearing are as far away from contact with the clutch as possible.

Normally with no cylinder fitted the fork, just using fingers, should slide the release bearing into contact with the clutch pressure plate ( fork toward the gearbox ) and away from the pressure plate ( fork toward the engine ) with from memory about 1 inch free play.

If you are not familiar with the arrangement this pic may help.

Ron.

- Craven

- Coveted Fifth Gear

- Posts: 1633

- Joined: 14 Sep 2013

Thanks Ron

So looking at your picture plus the one on rdent.com its more that the clutch release fork won't pivot forward? I have no idea what to cause of that could be, as a reminder I can engage all of the gears including reverse. This would make sense if the clutch release arm is back and therefore not engaging?

Thanks for the advice - any other ideas on why the clutch release fork won't move forward would be great to know.

Regards

Gareth

So looking at your picture plus the one on rdent.com its more that the clutch release fork won't pivot forward? I have no idea what to cause of that could be, as a reminder I can engage all of the gears including reverse. This would make sense if the clutch release arm is back and therefore not engaging?

Thanks for the advice - any other ideas on why the clutch release fork won't move forward would be great to know.

Regards

Gareth

To get something you've never had, you need to do something you've never done!

- GHill

- Second Gear

- Posts: 210

- Joined: 06 Sep 2014

Hi Gareth,

Is it possible that the fork has been bent, so that the bearing end has reached the end of it`s travel and cannot move any further.

It should be possible to inspect this through the fork hole after removing the gaiter.

You should be able to see the release bearing moving to touch the clutch- ( or not ).

It is a free pivot and no effort should be required.

Eric in Burnley

1967 S3SE DHC

Is it possible that the fork has been bent, so that the bearing end has reached the end of it`s travel and cannot move any further.

It should be possible to inspect this through the fork hole after removing the gaiter.

You should be able to see the release bearing moving to touch the clutch- ( or not ).

It is a free pivot and no effort should be required.

Eric in Burnley

1967 S3SE DHC

- ericbushby

- Coveted Fifth Gear

- Posts: 1363

- Joined: 13 Jun 2011

Hi Gareth,

In my experience with no cylinder fitted there is always enough free play in the fork to feel the action of the bearing being moved against and away from the clutch.

What are the background details, has this problem just arisen on replacing the slave on an otherwise working system or has the clutch been replaced? All gears can be selected without an operational clutch.

Ron.

In my experience with no cylinder fitted there is always enough free play in the fork to feel the action of the bearing being moved against and away from the clutch.

What are the background details, has this problem just arisen on replacing the slave on an otherwise working system or has the clutch been replaced? All gears can be selected without an operational clutch.

Ron.

- Craven

- Coveted Fifth Gear

- Posts: 1633

- Joined: 14 Sep 2013

Hi Chaps

Some background for context:

- Used the car all summer absolutely fine

- Towards the end of summer I had the 'feeling' that the clutch travel was not very far between engaging and disengaging (however I was getting in and out of the Lotus plus my modern ford quite a lot so just assumed it was related to the different cars)

- In the autumn just before my holiday and with decent weather I went to take if for a run and the clutch just sank to the floor

- On investigating the clutch slave cylinder had fluid all over it and a massive split in the dust cover (no 26 on rdent.com - plus 2 --> clutch --> housing plate)

- I ordered the replacement repair kit, disassembled, cleaned and then went on holiday for 3(ish) weeks, when I came back it was 12 hour days, 6 days a week at work so was at least 5 weekends before I could look at replacing the parts.

- As I recall the fork moved forward and backwards quite freely, it was definitely towards the back when I removed the clutch slave in any case.

- As I cleaned and reassembled I put the spring on which brought the clutch release fork forward, thereafter I haven't been able to move it backwards.

- I posted on the forum, wound the nut all the way in, fitted the slave and bled (sort of) the cylinders.

- I can see the cylinder apply pressure to the clutch release fork when the pedal is depressed

- I haven't yet removed the gaiter to see if I can see this through the fork hole (one for next weekend now)

Thanks again gents for your thoughts - keep 'em coming

Regards

Gareth

Some background for context:

- Used the car all summer absolutely fine

- Towards the end of summer I had the 'feeling' that the clutch travel was not very far between engaging and disengaging (however I was getting in and out of the Lotus plus my modern ford quite a lot so just assumed it was related to the different cars)

- In the autumn just before my holiday and with decent weather I went to take if for a run and the clutch just sank to the floor

- On investigating the clutch slave cylinder had fluid all over it and a massive split in the dust cover (no 26 on rdent.com - plus 2 --> clutch --> housing plate)

- I ordered the replacement repair kit, disassembled, cleaned and then went on holiday for 3(ish) weeks, when I came back it was 12 hour days, 6 days a week at work so was at least 5 weekends before I could look at replacing the parts.

- As I recall the fork moved forward and backwards quite freely, it was definitely towards the back when I removed the clutch slave in any case.

- As I cleaned and reassembled I put the spring on which brought the clutch release fork forward, thereafter I haven't been able to move it backwards.

- I posted on the forum, wound the nut all the way in, fitted the slave and bled (sort of) the cylinders.

- I can see the cylinder apply pressure to the clutch release fork when the pedal is depressed

- I haven't yet removed the gaiter to see if I can see this through the fork hole (one for next weekend now)

Thanks again gents for your thoughts - keep 'em coming

Regards

Gareth

To get something you've never had, you need to do something you've never done!

- GHill

- Second Gear

- Posts: 210

- Joined: 06 Sep 2014

the fork is known to crack and bend or come off the pivot. You can see it through the gaiter. Adjusting the rod to zero clearance and then stepping on the clutch is a potential cause in addition to just time and use. Heavy duty forks are available and expensive.

Eric

64 S1 Hart

Eric

64 S1 Hart

-

ecamiel - Third Gear

- Posts: 263

- Joined: 02 Oct 2003

Your description of:

" I went to take if for a run and the clutch just sank to the floor

- On investigating the clutch slave cylinder had fluid all over it and a massive split in the dust cover"

I think you have experienced a catastrophic failure of either the actual clutch fork inside the bell-housing or even more likely, the actual clutch diaphragm. I'll bet that when your clutch "went to the floor" this was actually the fork and release bearing pushing through the weakened diaphragm.I don't think this was a failure of the slave cylinder, but rather the failed cylinder was a result of the actual clutch cover/pressure plate failure which allowed the slave cylinder to over-travel.

To repair, you will need to replace the pressure plate, release bearing and driven disc and have the free play between the release bearing and diaphragm set properly. There is a small spring connecting fork arm to the bell-housing, which keeps the release bearing from dragging on the diaphragm, causing wear and the eventual failure as I have suggested.

I hope I am wrong, but I don't think so. Good luck.

Roger

" I went to take if for a run and the clutch just sank to the floor

- On investigating the clutch slave cylinder had fluid all over it and a massive split in the dust cover"

I think you have experienced a catastrophic failure of either the actual clutch fork inside the bell-housing or even more likely, the actual clutch diaphragm. I'll bet that when your clutch "went to the floor" this was actually the fork and release bearing pushing through the weakened diaphragm.I don't think this was a failure of the slave cylinder, but rather the failed cylinder was a result of the actual clutch cover/pressure plate failure which allowed the slave cylinder to over-travel.

To repair, you will need to replace the pressure plate, release bearing and driven disc and have the free play between the release bearing and diaphragm set properly. There is a small spring connecting fork arm to the bell-housing, which keeps the release bearing from dragging on the diaphragm, causing wear and the eventual failure as I have suggested.

I hope I am wrong, but I don't think so. Good luck.

Roger

'67 Elan S3 SS DHC

'67 Elan FHC pre-airflow

'67 Elan S3 SE upgrade to 26R by Original owner

'58 Eleven S2 (ex-works)

'62 20/22 FJ (ex-Yamura)

'70 Elan +2S RHD

'61 20 FJ project

'76 Modus M1 F3

'67 Elan FHC pre-airflow

'67 Elan S3 SE upgrade to 26R by Original owner

'58 Eleven S2 (ex-works)

'62 20/22 FJ (ex-Yamura)

'70 Elan +2S RHD

'61 20 FJ project

'76 Modus M1 F3

- Elan45

- Coveted Fifth Gear

- Posts: 2518

- Joined: 23 Nov 2008

Thanks Guys

Not a good prognosis then?

This weekend I will take the tunnel cover off and have a peer down the hole where the gear stick is.

Haven't 'played' with a clutch before, so that will be exciting - any specific tools required before I start? Im thinking at least the clutch location tool?

Regards

Gareth

Not a good prognosis then?

This weekend I will take the tunnel cover off and have a peer down the hole where the gear stick is.

Haven't 'played' with a clutch before, so that will be exciting - any specific tools required before I start? Im thinking at least the clutch location tool?

Regards

Gareth

To get something you've never had, you need to do something you've never done!

- GHill

- Second Gear

- Posts: 210

- Joined: 06 Sep 2014

Gareth,

Pull the gaiter on the side of the bell housing off, where the clutch fork enters, and have a look in there.

Eric in Burnley

Pull the gaiter on the side of the bell housing off, where the clutch fork enters, and have a look in there.

Eric in Burnley

- ericbushby

- Coveted Fifth Gear

- Posts: 1363

- Joined: 13 Jun 2011

Gareth,

Yeah, you'll need a clutch alignment tool and of course, a way to lift the engine out.

But first, pull the gaiter and have a look inside. If I am correct in my diagnosis, you should be able to see the trouble inside. and maybe another Elan.net member could stop by, observe and give a 2nd opinion.

Roger

Yeah, you'll need a clutch alignment tool and of course, a way to lift the engine out.

But first, pull the gaiter and have a look inside. If I am correct in my diagnosis, you should be able to see the trouble inside. and maybe another Elan.net member could stop by, observe and give a 2nd opinion.

Roger

'67 Elan S3 SS DHC

'67 Elan FHC pre-airflow

'67 Elan S3 SE upgrade to 26R by Original owner

'58 Eleven S2 (ex-works)

'62 20/22 FJ (ex-Yamura)

'70 Elan +2S RHD

'61 20 FJ project

'76 Modus M1 F3

'67 Elan FHC pre-airflow

'67 Elan S3 SE upgrade to 26R by Original owner

'58 Eleven S2 (ex-works)

'62 20/22 FJ (ex-Yamura)

'70 Elan +2S RHD

'61 20 FJ project

'76 Modus M1 F3

- Elan45

- Coveted Fifth Gear

- Posts: 2518

- Joined: 23 Nov 2008

Hi Chaps

Managed to get out of work earlier than normal so managed to have a look as suggested - to be honest it was very dark but I did manage to take a few pictures.

Look at the rdent.com website then it looks like the clutch release fork spring has fallen off (if this is possible) as you can clearly see a gap on the clutch release pin.

First the rdent.com picture - specifically looking at parts 18 & 19

Then looking at my clutch you can clearly see a gap in the clutch release pin

What are the thoughts of the forum? How easy is it to put the fork back on the clutch release pin and add the spring?

Regards

Gareth

Managed to get out of work earlier than normal so managed to have a look as suggested - to be honest it was very dark but I did manage to take a few pictures.

Look at the rdent.com website then it looks like the clutch release fork spring has fallen off (if this is possible) as you can clearly see a gap on the clutch release pin.

First the rdent.com picture - specifically looking at parts 18 & 19

Then looking at my clutch you can clearly see a gap in the clutch release pin

What are the thoughts of the forum? How easy is it to put the fork back on the clutch release pin and add the spring?

Regards

Gareth

To get something you've never had, you need to do something you've never done!

- GHill

- Second Gear

- Posts: 210

- Joined: 06 Sep 2014

Hi Gareth,

Looks to me as if the pin has moved away from the bellhouse, the bright section you can see should be a press fit into its hole in the bellhousing.

If you are lucky! Find a suitable flat lever to place between the square hole edge and the left hand side of the fork, lever to force the pin back into the bellhousing.

Next

Ron.

Looks to me as if the pin has moved away from the bellhouse, the bright section you can see should be a press fit into its hole in the bellhousing.

If you are lucky! Find a suitable flat lever to place between the square hole edge and the left hand side of the fork, lever to force the pin back into the bellhousing.

Next

Ron.

- Craven

- Coveted Fifth Gear

- Posts: 1633

- Joined: 14 Sep 2013

As another poster has suggested, have you checked to ensure the clutch fork is not bent? This part was only ever designed for a 1,500cc pushrod Mk.1 Cortina (it's the same 109E part). It's stressed even when asked to operate a standard twin cam clutch. It frequently breaks in RS/twin cam Fords hence Burtons have an uprated item available which I would recommend instead of the standard part. If it was bent this would allow the arm to move forward along with the pivot which is attached to it with a clip. Link to Burton part attached:

http://www.burtonpower.com/clutch-fork- ... 2e205.html

http://www.burtonpower.com/clutch-fork- ... 2e205.html

1970 Ford Escort Twin Cam

1972 Ford Escort GT1600 Twin Cam

1980 Ford Escort 2.0 Ghia

Peugeot 505 GTI Wagons (5spdx1) (Autox1)

2022 Ford Fiesta ST.

1972 Ford Escort GT1600 Twin Cam

1980 Ford Escort 2.0 Ghia

Peugeot 505 GTI Wagons (5spdx1) (Autox1)

2022 Ford Fiesta ST.

- 2cams70

- Coveted Fifth Gear

- Posts: 2050

- Joined: 10 Jun 2015

28 posts

• Page 1 of 2 • 1, 2

Total Online:

Users browsing this forum: No registered users and 16 guests