+2 Alloy Wheel Collar Needed !

62 posts

• Page 4 of 5 • 1, 2, 3, 4, 5

CBUEB1771 wrote:khamai wrote:Eliminates the problem of the K/O nut loosening over time caused by the expansion/contraction of the alloy wheel (due to temperature changes and brake heating). On the test wheels we did not have the thrust ring and the K/O nuts came loose within a couple hundred miles of normal street driving.

Interesting comment, the steel wheels can deform elastically when the knock-on nut is brought up to torque. The elastic deformation allows the nut to remain tight through temperature cycling.

Does this mean Lotus did a similar thing for their alloys by using steel for the Alloy Only Spinner/Nut?

Thx muchly Kiyoshi. Clears up a lot. I guess we will have to have something custom made up for the Minilite if we feel the round to bevel profile is not adequate.

Given Minilite has confirmed I have assembled their design correctly with all required parts, and there is essentially no effective difference to the profile miss-match to the Minilite thrust ring if using Alloy Only, Steel Wheel Only, or Unmarked Who Knows Spinner/Nuts, I guess I am comfortable with my set-up as installed. Will snug them up and go for a drive!

Stu

1969 Plus 2 Federal LHD

1969 Plus 2 Federal LHD

-

stugilmour - Coveted Fifth Gear

- Posts: 2063

- Joined: 03 Sep 2007

Russ, if I put a minilite on a hub, I get 6 full turns of the spinner before tight. I get 9 full turns with the same spinner/hub, but on a steel wheel. There are definitely less threads engaged - on mine anyway. Maybe my minilites are thicker than others?

Stu, how many full turns of the nut/spinner do you get before it's tight?

The 'alloy wheel only' nut is a bit of a puzzle. Maybe they were marked that way for a short time when alloy wheels were first introduced.

Gary, I tried a magnet - they are both non-magnetic using a normal magnet, but both are mildly magnetic using a super ('rare earth') magnet. As far as I can tell they are the same brass material.

Kiyoshi, I like your thrust ring profile. I think the conical surface would give the best spinner seat & grip. A pity minilite don't make these.

Hopefully the rounded minilite rings will be OK & spinners wil stay tight. Will find out when I get to drive it.

Grant

Stu, how many full turns of the nut/spinner do you get before it's tight?

The 'alloy wheel only' nut is a bit of a puzzle. Maybe they were marked that way for a short time when alloy wheels were first introduced.

Gary, I tried a magnet - they are both non-magnetic using a normal magnet, but both are mildly magnetic using a super ('rare earth') magnet. As far as I can tell they are the same brass material.

Kiyoshi, I like your thrust ring profile. I think the conical surface would give the best spinner seat & grip. A pity minilite don't make these.

Hopefully the rounded minilite rings will be OK & spinners wil stay tight. Will find out when I get to drive it.

Grant

- Grant K

- First Gear

- Posts: 22

- Joined: 04 Dec 2009

Hi Grant

Thanks for trying the magnet. It just didn't look like the beat up spinners that I have. Here is a picture of another wheel that I have, the JAP Magna. there are 2 sizes 13 x 6 and 13 x 7, nice and light wheels but they leak air fast. They have a pretty small contact ring that matches the spinners angle. I have not used them other than to roll the Elan around.

Thanks for trying the magnet. It just didn't look like the beat up spinners that I have. Here is a picture of another wheel that I have, the JAP Magna. there are 2 sizes 13 x 6 and 13 x 7, nice and light wheels but they leak air fast. They have a pretty small contact ring that matches the spinners angle. I have not used them other than to roll the Elan around.

-

garyeanderson - Coveted Fifth Gear

- Posts: 3391

- Joined: 12 Sep 2003

Gary,

Don't worry, they work just fine with plain old 'undo' spinners!

To be frank, if I hadn't seen the photographic evidence on this thread I wouldn't have believed the alloy/non alloy nut/spinner story. Over the years I've only seen the normal 'undo' marked and the alloy 26R type. Live and learn, eh?

Some observations:-

Perhaps the 52 deg. measurement is the key? Clearly from Gary's photo of the stack of spinner/nut/spinner, his, like mine are 45 deg. The corresponding taper in the JAP wheel is also the same. I have a steel +2 wheel whose 'witness' mark appears to be at a greater angle. I don't currently have a means of measuring this with any accuracy but it is towards the angle mentioned.

For comparison the thickness of the +2 wheel from hub mating face to the outside of the wheel is 27mm 20mm (1 1/16") and shows 22mm of thread from the very front face of the wheel giving nine and a half turns to hand tighten the wheel.

The JAP wheel is 32mm (1 1/4") thick and shows a thread of 15mm giving seven and a half turns to hand tighten.

The spinner I used has a total thread depth of 25 mm so there is no chance of bottoming out. Also I was always lead to believe the spinners are bronze. Different of course for the 26R which had bronze hubs and an alloy spinner with a totally different thread.

The JAP wheels do not use a separate ring. They have NEVER come loose. Well, except when all (the incorrect straight) drive pins dropped out! These I was wrongly sold to suit the S2 which of course should have the 'top hat' pin. The straight ones, according to R and R, were first introduced for the +2.

Before the advent of the Sarto tool, the spinners on the JAPs would 'change their tune' quite distinctly when fully tightened up with a copper headed hammer. Does this happen with the steels, Lotus and other alloys?

Lastly, the spinner 'sits in' the steel wheel whereas on the JAP it is proud. Enough to get Sarto's tool on but still using the middle part of the taper on spinner so another reason not to have a ring.

I hope I haven't muddied the waters to much!

Don't worry, they work just fine with plain old 'undo' spinners!

To be frank, if I hadn't seen the photographic evidence on this thread I wouldn't have believed the alloy/non alloy nut/spinner story. Over the years I've only seen the normal 'undo' marked and the alloy 26R type. Live and learn, eh?

Some observations:-

Perhaps the 52 deg. measurement is the key? Clearly from Gary's photo of the stack of spinner/nut/spinner, his, like mine are 45 deg. The corresponding taper in the JAP wheel is also the same. I have a steel +2 wheel whose 'witness' mark appears to be at a greater angle. I don't currently have a means of measuring this with any accuracy but it is towards the angle mentioned.

For comparison the thickness of the +2 wheel from hub mating face to the outside of the wheel is 27mm 20mm (1 1/16") and shows 22mm of thread from the very front face of the wheel giving nine and a half turns to hand tighten the wheel.

The JAP wheel is 32mm (1 1/4") thick and shows a thread of 15mm giving seven and a half turns to hand tighten.

The spinner I used has a total thread depth of 25 mm so there is no chance of bottoming out. Also I was always lead to believe the spinners are bronze. Different of course for the 26R which had bronze hubs and an alloy spinner with a totally different thread.

The JAP wheels do not use a separate ring. They have NEVER come loose. Well, except when all (the incorrect straight) drive pins dropped out! These I was wrongly sold to suit the S2 which of course should have the 'top hat' pin. The straight ones, according to R and R, were first introduced for the +2.

Before the advent of the Sarto tool, the spinners on the JAPs would 'change their tune' quite distinctly when fully tightened up with a copper headed hammer. Does this happen with the steels, Lotus and other alloys?

Lastly, the spinner 'sits in' the steel wheel whereas on the JAP it is proud. Enough to get Sarto's tool on but still using the middle part of the taper on spinner so another reason not to have a ring.

I hope I haven't muddied the waters to much!

Roy

'65 S2

'65 S2

-

elj221c - Fourth Gear

- Posts: 722

- Joined: 12 Sep 2003

Sarto here. I just checked my Panasports wheels and the spinner had 6 full turn to tight. The photo shows that most of the beveled portion has full contact and used most of the bevel's surface.

I use 190 foot lbs of torque and have not had a re-occurrence of the spinner coming loose.

Sarto

EDITED I just counted the total number of threads on the spinner and to my best eye count, its 9 and the three eared spinner on my Panasports uses 6 full turns. That sounds like a secured wheel. Any thoughts?

I use 190 foot lbs of torque and have not had a re-occurrence of the spinner coming loose.

Sarto

EDITED I just counted the total number of threads on the spinner and to my best eye count, its 9 and the three eared spinner on my Panasports uses 6 full turns. That sounds like a secured wheel. Any thoughts?

lotus elan 1966 S3 FHC

36/5785

LHD

36/5785

LHD

-

mac5777 - Fourth Gear

- Posts: 537

- Joined: 05 Jul 2004

Grant K wrote:Russ, if I put a Minilite on a hub, I get 6 full turns of the spinner before tight. I get 9 full turns with the same spinner/hub, but on a steel wheel. There are definitely less threads engaged - on mine anyway. Maybe my Minilites are thicker than others?

Stu, how many full turns of the nut/spinner do you get before it's tight?

The 'alloy wheel only' nut is a bit of a puzzle. Maybe they were marked that way for a short time when alloy wheels were first introduced.

Gary, I tried a magnet - they are both non-magnetic using a normal magnet, but both are mildly magnetic using a super ('rare earth') magnet. As far as I can tell they are the same brass material.

Kiyoshi, I like your thrust ring profile. I think the conical surface would give the best spinner seat & grip. A pity Minilite don't make these.

Hopefully the rounded Minilite rings will be OK & spinners will stay tight. Will find out when I get to drive it.

Grant

Grant, I am about 6 1/2 turns to tight. This is with the deeper Minilite thrust ring as per Russ' photo above and Federal Octagon nut marked only "Undo". The edge of the nut is slightly proud of the thrust ring when tightened.

I am not sure of the applied torque, but trying for 200 to 220 lb ft. I was distorting my flat RD Enterprises supplied wrench trying to get them tight. My wrench is different than the one Ray shows on his site now, which looks a bit more robust.

After my rear wheel almost fully exited stage left last year, I purchased the JAS' Octagon wrench shown here. Great bit of kit, just clears the Plus 2 fender with the pipe handle. Would be great if it would accept a torque wrench like Sarto uses.

elan-f14/octagon-spinner-tool-t20582.html

I immediately bent the pipe handle I bought at Home Depot. Inserted a smaller solid steel bar inside the pipe, and take it to where it is almost bending both of these. To paraphrase the Sheriff in Jaws, "I think we are going to need a bigger bar".

Agree the Panasport bevel looks way better. I am going to make sure I have the Minilites pretty tight.

Stu

1969 Plus 2 Federal LHD

1969 Plus 2 Federal LHD

-

stugilmour - Coveted Fifth Gear

- Posts: 2063

- Joined: 03 Sep 2007

Nice wheels Gary. Would look good on the right car, but flaring wheel arches tastfully is always a challenge. Maybe a thick coat of paint on the inside will seal them.

Thanks Stu & Sarto for confirming 6 threads into the spinner is normal. Can't help thinking 9 threads for steel wheels is better, but since my steel wheels are shot, I'll just have to make sure the spinners are nice & tight on the minilites.

That JAS tool is great. I don't think it would be difficult to get a consistent torque with a suitably long (& strong enough) bar.

I don't know why, but I like the the slightly dangerous look of the 3 eared spinners, so I'll get some new ones when they are available again.

What was this thread about again?

Thanks Stu & Sarto for confirming 6 threads into the spinner is normal. Can't help thinking 9 threads for steel wheels is better, but since my steel wheels are shot, I'll just have to make sure the spinners are nice & tight on the minilites.

That JAS tool is great. I don't think it would be difficult to get a consistent torque with a suitably long (& strong enough) bar.

I don't know why, but I like the the slightly dangerous look of the 3 eared spinners, so I'll get some new ones when they are available again.

What was this thread about again?

- Grant K

- First Gear

- Posts: 22

- Joined: 04 Dec 2009

Grant K wrote:What was this thread about again?

Collars.....or spinners.....aw, nuts!

I knew I would muddy things!

If as suggested, Minilite just copied Lotus, maybe you could ask if the metal they used would be suitable to use without the ring and appropriately profiled as in the JAP scenario. This would obviously depend on the boss thickness as well. From Grant's 6 turns it sounds like it would be OK. In fact, without a ring there would be more engagement.

Just because Sarto showed us his, I will show you mine......

Oh, and I reckon 10 full threads in my spinner which equates to my measurement of thread depth of 25mm with a 2.5mm pitch. The contact width is approximately 4mm. The bore in the wheel is 62mm. (2.5")

Roy

'65 S2

'65 S2

-

elj221c - Fourth Gear

- Posts: 722

- Joined: 12 Sep 2003

Grant K wrote:Nice wheels Gary. Would look good on the right car, but flaring wheel arches tastfully is always a challenge. Maybe a thick coat of paint on the inside will seal them.

What was this thread about again?

Hi Grant

I'd rather have bolt-ons but I have these and these arches will work with them until I can afford or find something else thats suitable. I have read the contact cement will seal them, I just haven't taken the time to dismount the tires and do it, not at the top of the priority list yet. Needs a lot of work still before that floats to the top...

-

garyeanderson - Coveted Fifth Gear

- Posts: 3391

- Joined: 12 Sep 2003

elj221c wrote: I knew I would muddy things!

ermmmmm...

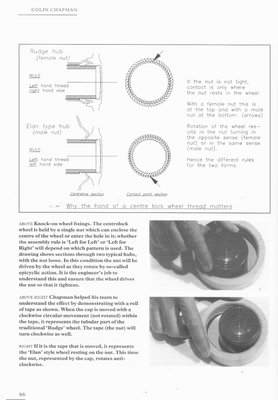

Do the "rules" for right & left handed threads (as described below) still hold when there is no direct contact between wheel and nut/spinner?

Does the interference fit between wheel & insert/collar mean they act as one assembly?

Cheers - Richard

- ardee_selby

- Coveted Fifth Gear

- Posts: 2197

- Joined: 30 Sep 2003

ardee_selby wrote:

Does the interference fit between wheel & insert/collar mean they act as one assembly?

Cheers - Richard

I would say so. There are no collars on a steel wheel and Lotus put the collar on their alloys without changing the left, right, red/green as far as I am aware.

Someone with Lotus alloys ?.............

Roy

'65 S2

'65 S2

-

elj221c - Fourth Gear

- Posts: 722

- Joined: 12 Sep 2003

As a follow-up comment & stating the obvious -

The "depth" of the trust ring is critical. The "depth" being the amount that the thrust ring stands proud of the wheel, since that "depth" contributes to the over all distance between the wheel's mating face (to the hub) and where the K/O nut will fit when tightened. In the case of the Panasport we had to find a "depth" that would allow for clearance between the K/O nut ears and the wheel's spokes yet keep the overall thickness thin enough allow for the K/O nut to properly engage with the K/O threads. In the end it was a bit of a compromise, not too thick of a ring and thick enough to give enough room between ears and spokes. Make sense?

Of course Sarto's lovely 3-ear tool helps, lessening the need for more space between ears and spokes. K/O nuts users should have wisely dumped the factory wrench for a proper socket.

Cheers,

Kiyoshi

The "depth" of the trust ring is critical. The "depth" being the amount that the thrust ring stands proud of the wheel, since that "depth" contributes to the over all distance between the wheel's mating face (to the hub) and where the K/O nut will fit when tightened. In the case of the Panasport we had to find a "depth" that would allow for clearance between the K/O nut ears and the wheel's spokes yet keep the overall thickness thin enough allow for the K/O nut to properly engage with the K/O threads. In the end it was a bit of a compromise, not too thick of a ring and thick enough to give enough room between ears and spokes. Make sense?

Of course Sarto's lovely 3-ear tool helps, lessening the need for more space between ears and spokes. K/O nuts users should have wisely dumped the factory wrench for a proper socket.

Cheers,

Kiyoshi

**************

Life is more fun behind the wheel of a Lotus!

www.gglotus.org

www.gglotus.org/blog

Life is more fun behind the wheel of a Lotus!

www.gglotus.org

www.gglotus.org/blog

-

khamai - Third Gear

- Posts: 266

- Joined: 20 Oct 2003

Grant K wrote:Nice wheels Gary. Would look good on the right car, but flaring wheel arches tastfully is always a challenge.

Page 1 of this thread shows my car on the same size JAPs as Gary's. I like it......

Grant K wrote:Maybe a thick coat of paint on the inside will seal them.

I have a 'leaker' but that is because the tyre bead wire has blown the tyre. (over 20 years since the car has been driven!) The paint doesn't have to be thick. I used a couple of sparing coats of Smoothrite rattle can.

Sorry, way of topic now!

Roy

'65 S2

'65 S2

-

elj221c - Fourth Gear

- Posts: 722

- Joined: 12 Sep 2003

On Roy's photo of his three eared spinner shows the threads, I count 9 turns and if you can get 6 full turns, it should be secured.

On lotus steel wheels the spinner ears bend out away from the wheel and the further out my tool grips the ears the more clearance you get. Except on the Panasport/ Minilites the spokes get real close to the spinner's ears. My tool grips closer to the center to avoid the Panasport raised spokes and works well with steel wheels. The photo shows just how close the spinner's tips are to the wheel and how close the tool comes to the center part of the wheel without touching. The leather stops the tool from getting any closer.

Kiyoshi is correct with his design, the balance in the thrust ring thickness works well. If the center thrust ring was too thin the spinner could touch the wheel and leave very little room to hit the spinner with a hammer.

Sarto

On lotus steel wheels the spinner ears bend out away from the wheel and the further out my tool grips the ears the more clearance you get. Except on the Panasport/ Minilites the spokes get real close to the spinner's ears. My tool grips closer to the center to avoid the Panasport raised spokes and works well with steel wheels. The photo shows just how close the spinner's tips are to the wheel and how close the tool comes to the center part of the wheel without touching. The leather stops the tool from getting any closer.

Kiyoshi is correct with his design, the balance in the thrust ring thickness works well. If the center thrust ring was too thin the spinner could touch the wheel and leave very little room to hit the spinner with a hammer.

Sarto

- Attachments

lotus elan 1966 S3 FHC

36/5785

LHD

36/5785

LHD

-

mac5777 - Fourth Gear

- Posts: 537

- Joined: 05 Jul 2004

Ah, I must be thick! Now I see the problem!

Thanks Sarto.

Us JAP owners don't have this problem as you will see from the pics below. JAP, and I guess Wolfrace and Revolutions apart, it would seem there is to be a problem using the 'Minilite' style wheels adapted for our 5 pin KO situation. The Lotus originals also excepted I assume but why did they feel the need for the rings? Any Revolution and Wolfrace owners out there care to comment on their fitment? Did Lotus follow what Minilite did with their after market wheels or vice versa? Sarto, do the Halibrands use a steel ring?

Finally, apologies to Jon for a severe high-jacking!

Did you find yourself a spare ring?

Thanks Sarto.

Us JAP owners don't have this problem as you will see from the pics below. JAP, and I guess Wolfrace and Revolutions apart, it would seem there is to be a problem using the 'Minilite' style wheels adapted for our 5 pin KO situation. The Lotus originals also excepted I assume but why did they feel the need for the rings? Any Revolution and Wolfrace owners out there care to comment on their fitment? Did Lotus follow what Minilite did with their after market wheels or vice versa? Sarto, do the Halibrands use a steel ring?

Finally, apologies to Jon for a severe high-jacking!

Did you find yourself a spare ring?

Roy

'65 S2

'65 S2

-

elj221c - Fourth Gear

- Posts: 722

- Joined: 12 Sep 2003

62 posts

• Page 4 of 5 • 1, 2, 3, 4, 5

Total Online:

Users browsing this forum: No registered users and 6 guests