Tubular Anti Roll Bar

30 posts

• Page 2 of 2 • 1, 2

I think the large cornering forces are what can push the outer front bearing inward in the 26r aluminum bronze alloy hubs. These are brand new TTR hubs with around 500 road miles on them. The problem only arose while driving the car hard in corners to test the ARB.

There was a thread years back that discussed this mode of failure experienced during racing.

Quoting Rohan from 9 years ago:

? I have always stayed with the cast iron hubs on my competition Elan rather than add lightness with alloy hubs. The bearing races loosen as it is under high temp conditions. In an alloy hub it would be even worse and it does not look like the makers have got the fit tolerances right for hot hubs.?

At least it?s telling me perhaps I am pulling substantial g-forces in my test drives. On a private road. Otherwise I am sure I would be gaining some unwanted attention.

I probably should redo the other front bearing (cement it) before it fails as well.

There was a thread years back that discussed this mode of failure experienced during racing.

Quoting Rohan from 9 years ago:

? I have always stayed with the cast iron hubs on my competition Elan rather than add lightness with alloy hubs. The bearing races loosen as it is under high temp conditions. In an alloy hub it would be even worse and it does not look like the makers have got the fit tolerances right for hot hubs.?

At least it?s telling me perhaps I am pulling substantial g-forces in my test drives. On a private road. Otherwise I am sure I would be gaining some unwanted attention.

I probably should redo the other front bearing (cement it) before it fails as well.

'69 Elan S4 SE

Street 181 BHP

Original owner

Street 181 BHP

Original owner

- 1owner69Elan

- Fourth Gear

- Posts: 897

- Joined: 16 Jun 2015

1owner69Elan wrote:...., I discovered that the outer bearing race had shifted inward in the 26r alloy hub causing a loose condition on the bearing/hub. Apparently, this bearing movement was caused by my spirited ("racing type") test driving.

I have 26r alloy hubs and had simply pressed the bearings in, interference fit, with no bearing cement. As noted elsewhere on the Forum these alloy hubs can apparently be problematic.......

.

Good to see the setup is working for you. it is the combination of all the details you have done that enables an Elan to utilise the grip of modern tyres.

I don't understand the comments above about the hub becoming loose because the outer bearing race pressed into the hub moved. The bearing should be pressed up against a step in the hub and be unable to move inwards.

With alloy hubs the bearing races can become loose in the hub as the hub temperature can get high when racing and braking hard. This can allow the race to spin in the hub and wear the hub until it is loose and can move up and down but it generally cannot move in. If the the stub axle nut and D washer were loose I would suspect the bearings were not properly seated when the end float was set or the races not fully pressed home in the hub.

cheers

Rohan

-

rgh0 - Coveted Fifth Gear

- Posts: 8829

- Joined: 22 Sep 2003

Thanks Rohan for the comments.

I hope we are not getting confused with "inward" and "outward" terminology. My use: inward direction means toward the center of the car. Outward direction means away from the center of the car. The outer bearing is further from the center of the car than the inner one.

Thus, I am a bit confused about the comment about the outer bearing not being able to move inward. The outer front bearing on the TTR k/o hubs (as well as the standard hubs) is pressed to the outer side of the hub by approaching from the inner side of the hub and pushing outward up against a step. So, the result is that the outer race cannot move further outward but it can move inward. The movement inward is exactly how you remove the bearing race. Thus, this potential movement inward of the outer race, once installed, apparently needs to be arrested under driving conditions.

Upon initial installation, I am sure I pressed all the bearing races up against the stops. The wheels were tight with little end play. Although I admit I did not measure the end play instead using the approximate "feel" approach. I am using a dial indicator to precisely measure this now, along with the recent bearing replacement.

I hope we are not getting confused with "inward" and "outward" terminology. My use: inward direction means toward the center of the car. Outward direction means away from the center of the car. The outer bearing is further from the center of the car than the inner one.

Thus, I am a bit confused about the comment about the outer bearing not being able to move inward. The outer front bearing on the TTR k/o hubs (as well as the standard hubs) is pressed to the outer side of the hub by approaching from the inner side of the hub and pushing outward up against a step. So, the result is that the outer race cannot move further outward but it can move inward. The movement inward is exactly how you remove the bearing race. Thus, this potential movement inward of the outer race, once installed, apparently needs to be arrested under driving conditions.

Upon initial installation, I am sure I pressed all the bearing races up against the stops. The wheels were tight with little end play. Although I admit I did not measure the end play instead using the approximate "feel" approach. I am using a dial indicator to precisely measure this now, along with the recent bearing replacement.

'69 Elan S4 SE

Street 181 BHP

Original owner

Street 181 BHP

Original owner

- 1owner69Elan

- Fourth Gear

- Posts: 897

- Joined: 16 Jun 2015

On any Elan hub that I have seen the outer race is installed from the outside driving in. Thus the race cannot go inwards once installed and the nut and 'D' washer prevent it from going outwards. My aluminium hubs are Kelveden and are as described-my original hubs were as described and my 26R hubs in the eighties were as described. As Rohan said, there was a problem with the outer race coming loose in the aluminium/bronze 26R hubs-from rotational stress. We seem to be in the middle of a misunderstanding!

'65 S2 4844

- Davidb

- Fourth Gear

- Posts: 941

- Joined: 02 Jul 2009

OK. Now I am worried. Help!!

I checked my old standard knock-off hubs. And the front outer bearing journal is indeed installed as both Rohan and Davidb have indicated. From the outside - in. Then, pressed up against a step with reduced diameter.

Bearing journal

Slips into standard hub

But, the 26r hubs that I have from TTR:

1. The LM11910 outer bearing journal cannot fit into the hub from the outside. The hub ID is 1.68 inch. The bearing journal OD is 1.78. No way the bearing can slide into the hub from the outside. On the other hand, the standard hub ID is 1.784 - so the LM11910 readily slips inside.

TTR 26r front hub

Bearing journal too big to slip inside

2. So, do I have the wrong bearing (as supplied by TTR)? What was supplied (and consistent with the standard k/o hubs) was the LM11949/LM11910 pair. Or is this just a different (and perhaps flawed) hub design.

3. I don't have the 26r hubs disassembled at the moment. But, I installed the LM11910 journal the only way it could fit - from the backside. Moreover, the step inside these 26r hubs, for the outer bearings, faces the inside of the hub. So pushing a smaller bearing from the outside in would not encounter anything to stop it, as the step is of increasing diameter (not decreasing) in that direction.

Utterly perplexed. It seems that I definitely have a backwards situation, as described by others and from the original hubs, and one that lends itself to the bearing movement that I experienced. Not sure how I could have screwed this up with the parts as supplied.

Contacting TTR to get a clarification.

If anyone has any insights into this situation I would be grateful.

I checked my old standard knock-off hubs. And the front outer bearing journal is indeed installed as both Rohan and Davidb have indicated. From the outside - in. Then, pressed up against a step with reduced diameter.

Bearing journal

Slips into standard hub

But, the 26r hubs that I have from TTR:

1. The LM11910 outer bearing journal cannot fit into the hub from the outside. The hub ID is 1.68 inch. The bearing journal OD is 1.78. No way the bearing can slide into the hub from the outside. On the other hand, the standard hub ID is 1.784 - so the LM11910 readily slips inside.

TTR 26r front hub

Bearing journal too big to slip inside

2. So, do I have the wrong bearing (as supplied by TTR)? What was supplied (and consistent with the standard k/o hubs) was the LM11949/LM11910 pair. Or is this just a different (and perhaps flawed) hub design.

3. I don't have the 26r hubs disassembled at the moment. But, I installed the LM11910 journal the only way it could fit - from the backside. Moreover, the step inside these 26r hubs, for the outer bearings, faces the inside of the hub. So pushing a smaller bearing from the outside in would not encounter anything to stop it, as the step is of increasing diameter (not decreasing) in that direction.

Utterly perplexed. It seems that I definitely have a backwards situation, as described by others and from the original hubs, and one that lends itself to the bearing movement that I experienced. Not sure how I could have screwed this up with the parts as supplied.

Contacting TTR to get a clarification.

If anyone has any insights into this situation I would be grateful.

'69 Elan S4 SE

Street 181 BHP

Original owner

Street 181 BHP

Original owner

- 1owner69Elan

- Fourth Gear

- Posts: 897

- Joined: 16 Jun 2015

Oneowner: I just tried a 11910 outer race in my front hubs and it is a snug fit from the get-go. I use a 1 5/16th socket to drive the race into the hub until it hits the step and it is a Very snug fit--there is something wrong with your hubs/bearings!

'65 S2 4844

- Davidb

- Fourth Gear

- Posts: 941

- Joined: 02 Jul 2009

Davidb,

Thanks for the help.

There does indeed appear to be something "funny" about my hubs:

1. ID definitely too small to slide the bearings in. The difference of 0.10 inch is more than a tight fit and impossible to make fit. So something wrong.

2. The hub inner step that constrains the bearing is facing the wrong way.

Perhaps the Kelvedon and TTR 26r hubs are different, and the TTR ones not in a good way. To be seen. I have contacted TTR. It will be tomorrow before a reply.

Thanks for the help.

There does indeed appear to be something "funny" about my hubs:

1. ID definitely too small to slide the bearings in. The difference of 0.10 inch is more than a tight fit and impossible to make fit. So something wrong.

2. The hub inner step that constrains the bearing is facing the wrong way.

Perhaps the Kelvedon and TTR 26r hubs are different, and the TTR ones not in a good way. To be seen. I have contacted TTR. It will be tomorrow before a reply.

'69 Elan S4 SE

Street 181 BHP

Original owner

Street 181 BHP

Original owner

- 1owner69Elan

- Fourth Gear

- Posts: 897

- Joined: 16 Jun 2015

At this point, I don't know what to believe.

I have an S4 that originally had the larger stub axles. I did get new ones but thought they were same size.

Even, if a smaller bearing would be used the internal step is still the wrong way round.

We'll see what TTR has to say.

I notice that Kelvedon lists three different 26r front hubs. The differences seem to be in materials, not design:

1. Steel (?), least expensive

2. Alloy

3. Phosphor Bronze (apparently Kelvedon don't have these yet)

My TTR ones are Aluminum Bronze and the only 26r k/o's that TTR list.

Stay tuned.

Thanks again for your help.

I have an S4 that originally had the larger stub axles. I did get new ones but thought they were same size.

Even, if a smaller bearing would be used the internal step is still the wrong way round.

We'll see what TTR has to say.

I notice that Kelvedon lists three different 26r front hubs. The differences seem to be in materials, not design:

1. Steel (?), least expensive

2. Alloy

3. Phosphor Bronze (apparently Kelvedon don't have these yet)

My TTR ones are Aluminum Bronze and the only 26r k/o's that TTR list.

Stay tuned.

Thanks again for your help.

'69 Elan S4 SE

Street 181 BHP

Original owner

Street 181 BHP

Original owner

- 1owner69Elan

- Fourth Gear

- Posts: 897

- Joined: 16 Jun 2015

Mystery about 26r front hub outer bearings resolved.

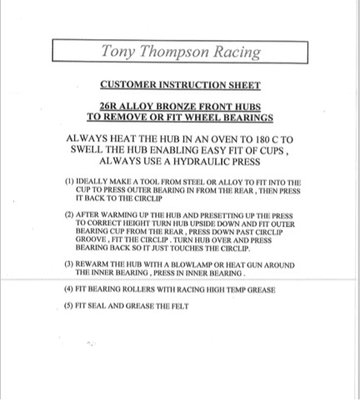

Turns out that the TTR 26r front hubs are apparently of different design to the experience of others, as noted here. Instead of the outer bearing being introduced to the hub from the outside, the TTR hubs have the outer bearing pressed toward the outside from inside the hub. Then, it is retained in place by an internal circlip that restrains any inward movement.

My problem was that I did not get the TTR instructions for the hubs, as above. And had no idea about the use of a circlip. Fortunately I haven't done that many miles before the missing circlips became evident and there is no lasting damage. I am in the process of redoing the front hubs as per the TTR instructions including the circlips.

Looking from the back of the hub, internal circlip retention of outer bearing

Turns out that the TTR 26r front hubs are apparently of different design to the experience of others, as noted here. Instead of the outer bearing being introduced to the hub from the outside, the TTR hubs have the outer bearing pressed toward the outside from inside the hub. Then, it is retained in place by an internal circlip that restrains any inward movement.

My problem was that I did not get the TTR instructions for the hubs, as above. And had no idea about the use of a circlip. Fortunately I haven't done that many miles before the missing circlips became evident and there is no lasting damage. I am in the process of redoing the front hubs as per the TTR instructions including the circlips.

Looking from the back of the hub, internal circlip retention of outer bearing

'69 Elan S4 SE

Street 181 BHP

Original owner

Street 181 BHP

Original owner

- 1owner69Elan

- Fourth Gear

- Posts: 897

- Joined: 16 Jun 2015

So, am I to conclude that all other 26r front hubs differ in design to the TTR ones, as far as the insertion of the outer bearing.

Is there an "original" configuration? Is the TTR hub a "modified version" or something original?

As far as the use of aluminum bronze for the material, this is undoubtedly problematic in high temperature situations, as noted by others.

A comment from an aluminum bronze supplier:

Thermal Expansion: Copper based alloys have a higher thermal expansion and contraction values than many other metals. Their approximate average expansion and contraction values are twice that of steel or cast iron. This is why it is necessary to adjust mating sizes if higher or lower than normal ambient temperature service is involved.

So why is aluminum bronze used? It is only marginally lighter than iron/steel.

Is there an "original" configuration? Is the TTR hub a "modified version" or something original?

As far as the use of aluminum bronze for the material, this is undoubtedly problematic in high temperature situations, as noted by others.

A comment from an aluminum bronze supplier:

Thermal Expansion: Copper based alloys have a higher thermal expansion and contraction values than many other metals. Their approximate average expansion and contraction values are twice that of steel or cast iron. This is why it is necessary to adjust mating sizes if higher or lower than normal ambient temperature service is involved.

So why is aluminum bronze used? It is only marginally lighter than iron/steel.

'69 Elan S4 SE

Street 181 BHP

Original owner

Street 181 BHP

Original owner

- 1owner69Elan

- Fourth Gear

- Posts: 897

- Joined: 16 Jun 2015

My original 26R hubs were similar in bearing installation to the standard hubs I recall. And the outer races would come loose...

My current front 26R hubs are Kelveden and made of an "aerospace' alloy-I forget which -they did tell me when I asked.

My current front 26R hubs are Kelveden and made of an "aerospace' alloy-I forget which -they did tell me when I asked.

'65 S2 4844

- Davidb

- Fourth Gear

- Posts: 941

- Joined: 02 Jul 2009

The front bearings on the TTR 26R hubs are now installed correctly with the internal circlip for the outer bearing.

Not sure if the TTR hub design is different to other 26R hubs (which they appear to be) but the bearings now seem to be quite secure with little chance of shifting as before.

Also, happy with the suspension setup with the 1" tubular ARB (Kelvedon).

Not sure if the TTR hub design is different to other 26R hubs (which they appear to be) but the bearings now seem to be quite secure with little chance of shifting as before.

Also, happy with the suspension setup with the 1" tubular ARB (Kelvedon).

'69 Elan S4 SE

Street 181 BHP

Original owner

Street 181 BHP

Original owner

- 1owner69Elan

- Fourth Gear

- Posts: 897

- Joined: 16 Jun 2015

30 posts

• Page 2 of 2 • 1, 2

Total Online:

Users browsing this forum: No registered users and 17 guests