Engine Block Material

16 posts

• Page 1 of 2 • 1, 2

My Engine block is the original as fitted in my 1968 +2. ------ Stamped / Cast 3020 E6015

Require to measure the Bore Wall Thickness with Ultrasonic Thickness Gauge, which has settings for Cast Iron, Grey Cast Iron and Nodular Cast Iron.

Miles Wilkins Twin Cam book says the block is ?Ford Cast-Iron?

Can anyone confirm if the block is, Cast Iron, Grey Cast Iron or Nodular Cast Iron, as the thickness readings are different for each material selection?

Thanks for any comments.

Require to measure the Bore Wall Thickness with Ultrasonic Thickness Gauge, which has settings for Cast Iron, Grey Cast Iron and Nodular Cast Iron.

Miles Wilkins Twin Cam book says the block is ?Ford Cast-Iron?

Can anyone confirm if the block is, Cast Iron, Grey Cast Iron or Nodular Cast Iron, as the thickness readings are different for each material selection?

Thanks for any comments.

Trevor

1968 Elan +2 50/0173

1968 Elan +2 50/0173

-

TeeJay - Fourth Gear

- Posts: 579

- Joined: 30 May 2007

Thanks Brian and Rohan for your comments.

I had read the manual, but in my keenness to try out the new tool; my focus was on getting some measurements.

Following your comments, I went back to the manual and then realised what ?Measuring by Velocity Setting? was. This Meter can increment the Velocity by steps of 10 m/s or 100 m/s.

So I can calibrate to a known thickness.

So I will be shortly going into the garage to re measure, adopting your suggestion.

Thanks again.

I had read the manual, but in my keenness to try out the new tool; my focus was on getting some measurements.

Following your comments, I went back to the manual and then realised what ?Measuring by Velocity Setting? was. This Meter can increment the Velocity by steps of 10 m/s or 100 m/s.

So I can calibrate to a known thickness.

So I will be shortly going into the garage to re measure, adopting your suggestion.

Thanks again.

Trevor

1968 Elan +2 50/0173

1968 Elan +2 50/0173

-

TeeJay - Fourth Gear

- Posts: 579

- Joined: 30 May 2007

RTFM always helps

When i measure the block thickness I normally record 4 measurements scans along the walls of the bore i.e. front back and each side looking for the minimum thick on each. I also scan the total bore looking for any other significantly thinner areas that may exist compared to these 4 axis measurements. You also need to try to pick up the wall thickness between the bore and the oil cross drilling between cylinders 2 and 3 which can be challenging.

You can then determine how to offset the boring to achieve the maximum wall thickness for the bore you want to go to. If your machine shop cant offset bore from the current bore centre line then find one who can. There is a limit to how far you can offset bore depending on how much bigger the new bore is as the cutter needs to still cut the full bore circle adequately to establish it as round.

What is an acceptable wall thickness is the next question and to some degree this depends on the area of minimum thickness and location. The thrust face of the piston is the most critical area and you don't want to have a large thin area on that side of the bore. In general when building my race engines I like to maintain 3 mm wall thickness minimum over the full bore if possible with 2.5 mm the absolute minimum in localized areas and I would aim for that to not be on the piston thrust side or over any significant area on the other 3 sides. A road engine will tolerate larger areas of 2.5 mm wall thickness but still keep it away from the piston thrust face.

cheers

Rohan

When i measure the block thickness I normally record 4 measurements scans along the walls of the bore i.e. front back and each side looking for the minimum thick on each. I also scan the total bore looking for any other significantly thinner areas that may exist compared to these 4 axis measurements. You also need to try to pick up the wall thickness between the bore and the oil cross drilling between cylinders 2 and 3 which can be challenging.

You can then determine how to offset the boring to achieve the maximum wall thickness for the bore you want to go to. If your machine shop cant offset bore from the current bore centre line then find one who can. There is a limit to how far you can offset bore depending on how much bigger the new bore is as the cutter needs to still cut the full bore circle adequately to establish it as round.

What is an acceptable wall thickness is the next question and to some degree this depends on the area of minimum thickness and location. The thrust face of the piston is the most critical area and you don't want to have a large thin area on that side of the bore. In general when building my race engines I like to maintain 3 mm wall thickness minimum over the full bore if possible with 2.5 mm the absolute minimum in localized areas and I would aim for that to not be on the piston thrust side or over any significant area on the other 3 sides. A road engine will tolerate larger areas of 2.5 mm wall thickness but still keep it away from the piston thrust face.

cheers

Rohan

-

rgh0 - Coveted Fifth Gear

- Posts: 8829

- Joined: 22 Sep 2003

Rohan, again many thanks for your comments.

For information, the block is marked ?LB?, so according to all the rules should not have been bored oversize to 0.060?. But it was machined by a well known company who have a good reputation for the twin cam engine; he measured the Bore Walls and said it was possible.

Yes, the Wall Thk of oil cross drill was fun. I measured the depth of the oil channel and then marked the upper and lower positions on the bores of 2 & 3 Cyl, to give me a target position.

Final result was No 3 = 3.9mm, No 2 = 3.2mm. BUT I will re measure again with the sensor rotated by 90 degrees, as I read that this is a suggested technique.

Results posted below and would appreciate any comments.

Use Liners? New block? Pressure test the block?

Best Regards

For information, the block is marked ?LB?, so according to all the rules should not have been bored oversize to 0.060?. But it was machined by a well known company who have a good reputation for the twin cam engine; he measured the Bore Walls and said it was possible.

Yes, the Wall Thk of oil cross drill was fun. I measured the depth of the oil channel and then marked the upper and lower positions on the bores of 2 & 3 Cyl, to give me a target position.

Final result was No 3 = 3.9mm, No 2 = 3.2mm. BUT I will re measure again with the sensor rotated by 90 degrees, as I read that this is a suggested technique.

Results posted below and would appreciate any comments.

Use Liners? New block? Pressure test the block?

Best Regards

Trevor

1968 Elan +2 50/0173

1968 Elan +2 50/0173

-

TeeJay - Fourth Gear

- Posts: 579

- Joined: 30 May 2007

Hi Trevor

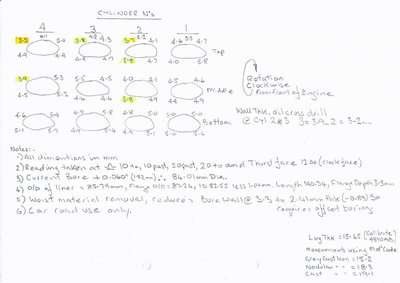

As i understand it your block has been bored 60 thou oversize to 84 mm and the thickness measurements you have taken are in the attached JPEG. The measurements are at 10, 20, 40 and 50 minutes versus 0 minutes / 12 o'clock at the thrust face of the block plus the thrust face at 0 minutes. The thrust face is at 90 degrees to the block front / rear axis and on the carb side.

Your ultrasonic gauge has been calibrated at 4890 m/s using one of the lugs on block which is not far off the standard grey cast iron velocity, so the thickness measurements should be good. I have measured velocities between 4800 and 5000 m/s across the blocks I have measured so yours in typical

From what I can see you have an excellent block that is at the top end of overall Cylinder casting OD at 92+ mm. The cylinder casting OD varies based on my measurements from a minimum of around 88 mm to average of 90 mm to maximum of 92 mm. Yours is at the very top end of what I have measured on around 30 plus blocks. Your bores are also nicely centered on this casting OD with consistent wall thickness above 4 mm at an 84 mm bore.

The 84 mm bore you have now is safe and relatively well centered on the casting. The minimum thickness of 3.3 mm in a limited area such as the top of cylinder 4 at 50 minutes is a low stress area and still plenty even for a high stress area. The thickness over the cross drilling also appears to be good

The Lotus original stamping e.g. LA / LAA / LB was based on a couple of thickness tests using special calipers through the casting plugs so it was only a rough guide and while it detected potential castings that could be bored larger than the Lotus standard 82.55 it failed to detect many that met the criteria these days based on a more comprehensive ultrasonic bore scan. In practice I see no real difference between new ford motor sport blocks and original blocks, non lotus original ford blocks, or L blocks and between LB blocks and LA blocks though I have only ever measure a couple of LA blocks. The casting technology is the same on all of the blocks and this limits the bore wall thickness to the range I have tested and any block may be thicker or thinner due to random variation in the actual casting.

With careful offset boring you could further use this block for a 85 mm race engine and those blocks are extremely rare. ..... For a road engine you have an absolutely solid block at 84 mm bore. I would examine the bore for any porosity and do a crack test on the bores and then pressure test the block to confirm nothing has been missed but given the thickness testing i would expect none of this to show a problem.

..... For a road engine you have an absolutely solid block at 84 mm bore. I would examine the bore for any porosity and do a crack test on the bores and then pressure test the block to confirm nothing has been missed but given the thickness testing i would expect none of this to show a problem.

cheers

Rohan

As i understand it your block has been bored 60 thou oversize to 84 mm and the thickness measurements you have taken are in the attached JPEG. The measurements are at 10, 20, 40 and 50 minutes versus 0 minutes / 12 o'clock at the thrust face of the block plus the thrust face at 0 minutes. The thrust face is at 90 degrees to the block front / rear axis and on the carb side.

Your ultrasonic gauge has been calibrated at 4890 m/s using one of the lugs on block which is not far off the standard grey cast iron velocity, so the thickness measurements should be good. I have measured velocities between 4800 and 5000 m/s across the blocks I have measured so yours in typical

From what I can see you have an excellent block that is at the top end of overall Cylinder casting OD at 92+ mm. The cylinder casting OD varies based on my measurements from a minimum of around 88 mm to average of 90 mm to maximum of 92 mm. Yours is at the very top end of what I have measured on around 30 plus blocks. Your bores are also nicely centered on this casting OD with consistent wall thickness above 4 mm at an 84 mm bore.

The 84 mm bore you have now is safe and relatively well centered on the casting. The minimum thickness of 3.3 mm in a limited area such as the top of cylinder 4 at 50 minutes is a low stress area and still plenty even for a high stress area. The thickness over the cross drilling also appears to be good

The Lotus original stamping e.g. LA / LAA / LB was based on a couple of thickness tests using special calipers through the casting plugs so it was only a rough guide and while it detected potential castings that could be bored larger than the Lotus standard 82.55 it failed to detect many that met the criteria these days based on a more comprehensive ultrasonic bore scan. In practice I see no real difference between new ford motor sport blocks and original blocks, non lotus original ford blocks, or L blocks and between LB blocks and LA blocks though I have only ever measure a couple of LA blocks. The casting technology is the same on all of the blocks and this limits the bore wall thickness to the range I have tested and any block may be thicker or thinner due to random variation in the actual casting.

With careful offset boring you could further use this block for a 85 mm race engine and those blocks are extremely rare.

cheers

Rohan

-

rgh0 - Coveted Fifth Gear

- Posts: 8829

- Joined: 22 Sep 2003

Very much appreciate your comments and time Rohan and its great to hear that the block is usable and not scrap.

So will proceed with; Porosity, Crack and Pressure Tests.

I had noted the Thrust measurements, but only on the exhaust side (12.00 hrs). Have now taken readings on both sides, Exhaust and Carbs at; Top, Middle and Bottom. See below.

Have also measured the Wall Thk oil cross Drill with sensor at 90 degrees,

No 3 = 3.9mm re 3.9mm and No 2 = 3.1mm re 3.2mm, so not much difference with the sensor @ 90 degree rotation.

At the start of measurement sessions, I always check the Lug to ensure its still reading at 15.7mm and again at the end of any readings. This just to confirm confidence with the batch of readings and the Gauge settings.

Exhaust 12.00hrs 4 3 2 1

Top 6.1 4.2 5.2 5.3

Mid 6.2 4.5 5.5 5.1

Bottom 6.4 5.6 3.1 5.6

Carbs @ 6.00hrs 4 3 2 1

Top 7.0 4.8 5.3 6.2

Mid 6.5 4.9 5.4 5.3

Bottom 7.0 4.7 5.4 6.2

Sorry cannot get the grid to line up, hope its readable.

Finally I have well and truly skinned my knuckle (forefinger); it just catches the top of the bore for every measurement, but well worth the effort.

Best Regards

So will proceed with; Porosity, Crack and Pressure Tests.

I had noted the Thrust measurements, but only on the exhaust side (12.00 hrs). Have now taken readings on both sides, Exhaust and Carbs at; Top, Middle and Bottom. See below.

Have also measured the Wall Thk oil cross Drill with sensor at 90 degrees,

No 3 = 3.9mm re 3.9mm and No 2 = 3.1mm re 3.2mm, so not much difference with the sensor @ 90 degree rotation.

At the start of measurement sessions, I always check the Lug to ensure its still reading at 15.7mm and again at the end of any readings. This just to confirm confidence with the batch of readings and the Gauge settings.

Exhaust 12.00hrs 4 3 2 1

Top 6.1 4.2 5.2 5.3

Mid 6.2 4.5 5.5 5.1

Bottom 6.4 5.6 3.1 5.6

Carbs @ 6.00hrs 4 3 2 1

Top 7.0 4.8 5.3 6.2

Mid 6.5 4.9 5.4 5.3

Bottom 7.0 4.7 5.4 6.2

Sorry cannot get the grid to line up, hope its readable.

Finally I have well and truly skinned my knuckle (forefinger); it just catches the top of the bore for every measurement, but well worth the effort.

Best Regards

Trevor

1968 Elan +2 50/0173

1968 Elan +2 50/0173

-

TeeJay - Fourth Gear

- Posts: 579

- Joined: 30 May 2007

Hi Trevor and Rohan.

I'm a bit late to this earlier discussion on measuring bore wall thicknesses, but as this is now some time ago, was wondering how you got on Trevor.

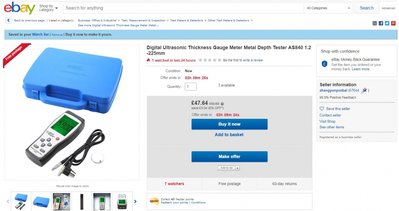

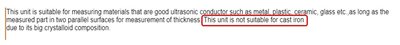

I've been looking at a similar device myself on Flea-Bay. This one look reasonable, given that I don't really want to pay out ?-Hundreds for a professional one.

https://www.ebay.co.uk/itm/Digital-Ultr ... fresh=true

Reading through the spec, it does mention that it is not suitable for "Cast Iron". However, from your previous post, setting it to a Velocity of 4890 m/s and using a rear mounting lug on the block as a "Set-Up/Accuracy Gauge", you have obviously got a fair result.

So:-

Question is..... Were you using the type of tester I've mentioned above, or were you using more expensive/professional equipment ?.

I'm a bit late to this earlier discussion on measuring bore wall thicknesses, but as this is now some time ago, was wondering how you got on Trevor.

I've been looking at a similar device myself on Flea-Bay. This one look reasonable, given that I don't really want to pay out ?-Hundreds for a professional one.

https://www.ebay.co.uk/itm/Digital-Ultr ... fresh=true

Reading through the spec, it does mention that it is not suitable for "Cast Iron". However, from your previous post, setting it to a Velocity of 4890 m/s and using a rear mounting lug on the block as a "Set-Up/Accuracy Gauge", you have obviously got a fair result.

So:-

Question is..... Were you using the type of tester I've mentioned above, or were you using more expensive/professional equipment ?.

John "Freddie" Nelson, Berks UK

26/3212 - Rebuilding

S4-Sprint DHC - Now at a new home.....

26/3212 - Rebuilding

S4-Sprint DHC - Now at a new home.....

- Fredtech

- Second Gear

- Posts: 69

- Joined: 19 Oct 2010

I use a Dakota PR-82 ultrasonic thickness tester. This was about A$1000 when I bought it a number of years ago now. It is a semi professional unit tailored for engine builders. A lot cheaper than the ones I have used for piping and pressure vessel and welding inspections at work but more expensive than the one your looking at.

Modern electronics and chinese manufacture has brought down the cost of many instruments so it may be OK but i would check that it has the range of adjustability to enable it to test cast iron in the cores satisfactorily.

cheers

Rohan

Modern electronics and chinese manufacture has brought down the cost of many instruments so it may be OK but i would check that it has the range of adjustability to enable it to test cast iron in the cores satisfactorily.

cheers

Rohan

-

rgh0 - Coveted Fifth Gear

- Posts: 8829

- Joined: 22 Sep 2003

Browsing the cheap Ebay options there appears to be a couple of Chinese manufactures selling under a range of names. Most say their device is not suitable for castings which is a critical capability for looking at cylinder heads and blocks. The Dakota instrument I use is specifically designed for this function.

I don't fully understand what is required to measure a casting versus a forged or rolled or extrude piece of metal but I presume it is how the instrument deals with small microscopic voids that will be present in most castings. If a Chinese cheap supplier says it does not work with castings then they have got enough complaints or returned product to include that warning so they don't have to give you a refund. The issue may be around the frequency of ultrasonic sound waves used. The cheap Chinese units appear to use a fixed number of 5 MHz frequency the Dakota gauge appears to use a range of 1 to 10 MHz and this may be a key distinction.

cheers

Rohan

I don't fully understand what is required to measure a casting versus a forged or rolled or extrude piece of metal but I presume it is how the instrument deals with small microscopic voids that will be present in most castings. If a Chinese cheap supplier says it does not work with castings then they have got enough complaints or returned product to include that warning so they don't have to give you a refund. The issue may be around the frequency of ultrasonic sound waves used. The cheap Chinese units appear to use a fixed number of 5 MHz frequency the Dakota gauge appears to use a range of 1 to 10 MHz and this may be a key distinction.

cheers

Rohan

-

rgh0 - Coveted Fifth Gear

- Posts: 8829

- Joined: 22 Sep 2003

Hi Rohan. Thanks for the further clarification. I'd guessed the same thing. Casting, and specifically Cast-Iron will more likely have a "Grainy" type structure, as I remember from apprentice days (many years ago). Hence used for things such as Lathe-Beds etc, as the cast-iron retains a certain amount of free carbon grains in the structure, hence they are self lubricating to a certain extent. This would possibly cause the difficulties in measuring the thickness with an Ultrasonic Source.

Thanks, J

Thanks, J

John "Freddie" Nelson, Berks UK

26/3212 - Rebuilding

S4-Sprint DHC - Now at a new home.....

26/3212 - Rebuilding

S4-Sprint DHC - Now at a new home.....

- Fredtech

- Second Gear

- Posts: 69

- Joined: 19 Oct 2010

Hi John, only just seen your questions, currently away from home.

After a detailed research, into types of ultrasonic gauges, hiring / buying I ended up buying from Amazon Uk.

Mine was a Landtek Instruments Ultrasonic Thickness Gauge Meter Digital 1.00 to 200.00mm Metal/Non-Metal at a cost of ?175.85 and its still at the same price. Important to me was that it does measure Gray, Nodular and Cast Iron.

It also has an adjustable Sound velocity: 500 - 9000m/s .

Link https://www.amazon.co.uk/gp/product/B00 ... UTF8&psc=1

I can recommend it, not the cheapest but a very good spec.

I followed Rohan excellent advice on the measurement method, including the cross drilling and was very grateful when he reviewed the results and confirmed the wall thickness were usable.

Some details below

Product description

Handheld microprocessor-controlled ultrasonic thickness gauge specifically designed to measure the thickness of metallic and

non-metallic materials such as aluminium, titanium, plastics, ceramics, glass, plastics including rubber and other good ultrasonic wave conductors.

Applicable to measure the thickness of many materials, e.g. Steel, Cast Iron, Aluminum, Red copper,

Brass, Zinc, Quartz glass, Polyethylene, PVC, Gray cast iron, Nodular cast iron.

Specification:

Operating Principle: ULTRASONIC

LCD display : 4 digits, 10 mm LCD

Measuring method: Ultrasonic pulse echo

Measuring range (metric/imperial): 1.0~200.00mm, 0.039-7.87inch (45 sharp steel)

Resolution: 0.1mm / 0.001 inch

Accuracy: ?(0.5%n+0.1)

Sound velocity: 500 - 9000m/s

Diameter of sensor : 10 mm (0.39' inch)

Length of sensor : 90 cm (35' inch)

Weight of sensor : approx. 40g

After a detailed research, into types of ultrasonic gauges, hiring / buying I ended up buying from Amazon Uk.

Mine was a Landtek Instruments Ultrasonic Thickness Gauge Meter Digital 1.00 to 200.00mm Metal/Non-Metal at a cost of ?175.85 and its still at the same price. Important to me was that it does measure Gray, Nodular and Cast Iron.

It also has an adjustable Sound velocity: 500 - 9000m/s .

Link https://www.amazon.co.uk/gp/product/B00 ... UTF8&psc=1

I can recommend it, not the cheapest but a very good spec.

I followed Rohan excellent advice on the measurement method, including the cross drilling and was very grateful when he reviewed the results and confirmed the wall thickness were usable.

Some details below

Product description

Handheld microprocessor-controlled ultrasonic thickness gauge specifically designed to measure the thickness of metallic and

non-metallic materials such as aluminium, titanium, plastics, ceramics, glass, plastics including rubber and other good ultrasonic wave conductors.

Applicable to measure the thickness of many materials, e.g. Steel, Cast Iron, Aluminum, Red copper,

Brass, Zinc, Quartz glass, Polyethylene, PVC, Gray cast iron, Nodular cast iron.

Specification:

Operating Principle: ULTRASONIC

LCD display : 4 digits, 10 mm LCD

Measuring method: Ultrasonic pulse echo

Measuring range (metric/imperial): 1.0~200.00mm, 0.039-7.87inch (45 sharp steel)

Resolution: 0.1mm / 0.001 inch

Accuracy: ?(0.5%n+0.1)

Sound velocity: 500 - 9000m/s

Diameter of sensor : 10 mm (0.39' inch)

Length of sensor : 90 cm (35' inch)

Weight of sensor : approx. 40g

Trevor

1968 Elan +2 50/0173

1968 Elan +2 50/0173

-

TeeJay - Fourth Gear

- Posts: 579

- Joined: 30 May 2007

An old thread, but I try to keep topics together as best I can.

Following advice on here about wall thickness (thanks to Rohan and others), I purchased a cheapo ultrasonic thickness measuring tool from eBay for £80. I have to admit, early indications are very positive. I have messed around with my block and it seems to measure the bell housing lug about right, and the sensor seems to cope with a curved bore wall OK. I try to post a few pictures.

A question for those who know about these things, I am assuming I will have rust build-up inside the water jacket. I intend to clear it all out, but for the purposes of an early health check on the block, will rust / sludge have an effect on the measurements I see on the thickness gauge?

As ever, thanks for any responses.

Andy.

Following advice on here about wall thickness (thanks to Rohan and others), I purchased a cheapo ultrasonic thickness measuring tool from eBay for £80. I have to admit, early indications are very positive. I have messed around with my block and it seems to measure the bell housing lug about right, and the sensor seems to cope with a curved bore wall OK. I try to post a few pictures.

A question for those who know about these things, I am assuming I will have rust build-up inside the water jacket. I intend to clear it all out, but for the purposes of an early health check on the block, will rust / sludge have an effect on the measurements I see on the thickness gauge?

As ever, thanks for any responses.

Andy.

68 Elan S3 HSCC Roadsports spec

71 Elan Sprint (being restored)

32 Standard 12

Various modern stuff

71 Elan Sprint (being restored)

32 Standard 12

Various modern stuff

- Andy8421

- Coveted Fifth Gear

- Posts: 1178

- Joined: 27 Mar 2011

16 posts

• Page 1 of 2 • 1, 2

Total Online:

Users browsing this forum: Loustaller, rjaxe and 34 guests