Head to Block Assembly Question

7 posts

• Page 1 of 1

Hi:

I'm a new member of this list. I came over from the Europa forum. I'm building my first twin cam engine and it seems the Europa site has more Renault engine members. I hope everyone is OK with this as we are related

I have the lower end of the engine assembled and the head has been done by John McCoy at Omnitech (but still needs final assembly). I have made an assembly list after reading Miles Wilkins book, the shop manual and this site and the Europa site. My list is below. I would appreciate any corrections, comments and suggestions.

Thanks,

Sherman

Windsor, Colorado

1. Find TDC (I am using a new crankshaft pulley that is unmarked). The new pulley is a gilmer drive from Dave Bean, as I am using their cartridge water pump.

3 methods that I know of, but I'm sure there are more:

a. Dial indicator; use magnetic deck bridge: TDC by rotating clockwise until the dial indicator drops to a certain reading, mark that on the flywheel, then rotate counterclockwise until the dial indicator reaches the same reading and mark the flywheel. TDC is half way between the two marks.

b. Dial indicator; use magnetic deck bridge. Slowly rotate the flywheel clockwise and stop when the piston reaches top dead center (TDC). This is the point where the needle reverses its direction on dial indicator as the flywheel is rotated.

Use deck bridge and attach dial indicator at edge of piston. Push down on both edge of piston at least 3 times and then zero out dial indicator. Push down on opposite side of piston and note reading on dial indicator. Divide that number by 2. Push piston down by that number and that is true top dead center.

c. Using piston stop and degree wheel. Attach degree wheel to crankshaft and put wire indicator on timing chest bolt. Line up to 0 degrees. Make sure piston is dropped down in bore a small amount. Attach piston stop. Rotate clockwise and note where on degree wheel piston hits piston stop. Rotate in anti clockwise direction and note where on degree wheel piston hits stop. Make sure readings are on both sides of TDC. Add degrees together and divide by 2. That is amount on each side of TDC. Reposition pointer to correct degree. Rotate engine to make sure that it is equal distance on pointer. Remove piston stop. 0 degree on degree wheel is now TDC

I don't know if I have written these out clearly, but I have an understanding of the concepts.

2. Mark new crankshaft pulley to match TDC mark on timing chest with true TDC.

3. Bolt crankshaft pulley on crankshaft

4. Lower pistons in block

5. Attach Timing Chain Idler to head. Per Miles Wilkins apply Loctite and torque to 45 lbs

6. Attach Brass plugs on exhaust side of head using Permatex thread sealer

7. Attach small grub screw to exhaust camshaft using Permatex thread sealer

8. Place cork gasket on block, covering both sides with The Right Stuff sealer

9. Spray both sides of Head Gasket with Permatex copper coat, wait 5 minutes to tack. Head gasket is from RD Enterprises and is a composite. I also have a copper head gasket, but my machinist suggested the composite with the copper coat.

10. Place Head Gasket on block and screw in two alignment studs (opposite left and right)

11. Place head to block oil drain tube on block.

12. Place block on head. (Make sure timing chain is resting on top of water pump housing and can be fished to top of block when needed.)

13. Place head bolts and timing chest bolts (remove alignment studs)

14. Torque head bolts (65 lbs in three stages 25, 45 & 65) Using ARP bolts

15. Torque timing chest bolts. 15 lbs. Per Miles Wilkins do 3 times to insure cork gasket compressed.

16. Raise pistons to TDC

17. Place oil seal on inlet camshaft. Use tape to make smooth transition over circlip groove (this is instead of using lotus tool). Use Right Stuff sealant where seal sits in head.

18. Put inlet sprocket on inlet camshaft.

19. Place in head and line up timing mark to top of head. Cam lobe on #4 just rocking ? see picture in Miles Wilkins book

20. Tighten caps evenly and then torque (9 lbs)

21. Put exhaust sprocket on exhaust camshaft

22 Place exhaust camshaft in head and line up timing mark to top of head Cam lobe on #4 just rocking ? see picture in Miles Wilkins book

23. Tighten caps evenly and then torque (9 lbs)

24. Remove inlet and exhaust sprockets

25. Fish up timing chain

26. Attach timing chain to inlet sprocket and then place on camshaft. Make sure timing marks are correct.

27. Attach timing chain to exhaust sprocket and then place on cam. May have to use vice grip on camshaft to move slightly to make sure timing marks are correct.

28. Install timing chain tensioner in block and adjust timing chain.

29. Rotate engine at least 2 times and make sure timing marks line up

30. Torque camshaft sprocket bolts and front pulley bolt to 25 lbs

Alternative per Miles Wilkins is to start with exhaust sprocket. Starting with inlet is per Elan website.

Do not turn camshafts without timing chain attached (can turn only a minimal amount) Valves can hit if turn.

Per number #5 above is Loctite correct in this location?

Is it correct that the Europa inlet camshaft is sealed by the alternator pulley bolt. Should Permatex sealant be used on this bolt?

I'm a new member of this list. I came over from the Europa forum. I'm building my first twin cam engine and it seems the Europa site has more Renault engine members. I hope everyone is OK with this as we are related

I have the lower end of the engine assembled and the head has been done by John McCoy at Omnitech (but still needs final assembly). I have made an assembly list after reading Miles Wilkins book, the shop manual and this site and the Europa site. My list is below. I would appreciate any corrections, comments and suggestions.

Thanks,

Sherman

Windsor, Colorado

1. Find TDC (I am using a new crankshaft pulley that is unmarked). The new pulley is a gilmer drive from Dave Bean, as I am using their cartridge water pump.

3 methods that I know of, but I'm sure there are more:

a. Dial indicator; use magnetic deck bridge: TDC by rotating clockwise until the dial indicator drops to a certain reading, mark that on the flywheel, then rotate counterclockwise until the dial indicator reaches the same reading and mark the flywheel. TDC is half way between the two marks.

b. Dial indicator; use magnetic deck bridge. Slowly rotate the flywheel clockwise and stop when the piston reaches top dead center (TDC). This is the point where the needle reverses its direction on dial indicator as the flywheel is rotated.

Use deck bridge and attach dial indicator at edge of piston. Push down on both edge of piston at least 3 times and then zero out dial indicator. Push down on opposite side of piston and note reading on dial indicator. Divide that number by 2. Push piston down by that number and that is true top dead center.

c. Using piston stop and degree wheel. Attach degree wheel to crankshaft and put wire indicator on timing chest bolt. Line up to 0 degrees. Make sure piston is dropped down in bore a small amount. Attach piston stop. Rotate clockwise and note where on degree wheel piston hits piston stop. Rotate in anti clockwise direction and note where on degree wheel piston hits stop. Make sure readings are on both sides of TDC. Add degrees together and divide by 2. That is amount on each side of TDC. Reposition pointer to correct degree. Rotate engine to make sure that it is equal distance on pointer. Remove piston stop. 0 degree on degree wheel is now TDC

I don't know if I have written these out clearly, but I have an understanding of the concepts.

2. Mark new crankshaft pulley to match TDC mark on timing chest with true TDC.

3. Bolt crankshaft pulley on crankshaft

4. Lower pistons in block

5. Attach Timing Chain Idler to head. Per Miles Wilkins apply Loctite and torque to 45 lbs

6. Attach Brass plugs on exhaust side of head using Permatex thread sealer

7. Attach small grub screw to exhaust camshaft using Permatex thread sealer

8. Place cork gasket on block, covering both sides with The Right Stuff sealer

9. Spray both sides of Head Gasket with Permatex copper coat, wait 5 minutes to tack. Head gasket is from RD Enterprises and is a composite. I also have a copper head gasket, but my machinist suggested the composite with the copper coat.

10. Place Head Gasket on block and screw in two alignment studs (opposite left and right)

11. Place head to block oil drain tube on block.

12. Place block on head. (Make sure timing chain is resting on top of water pump housing and can be fished to top of block when needed.)

13. Place head bolts and timing chest bolts (remove alignment studs)

14. Torque head bolts (65 lbs in three stages 25, 45 & 65) Using ARP bolts

15. Torque timing chest bolts. 15 lbs. Per Miles Wilkins do 3 times to insure cork gasket compressed.

16. Raise pistons to TDC

17. Place oil seal on inlet camshaft. Use tape to make smooth transition over circlip groove (this is instead of using lotus tool). Use Right Stuff sealant where seal sits in head.

18. Put inlet sprocket on inlet camshaft.

19. Place in head and line up timing mark to top of head. Cam lobe on #4 just rocking ? see picture in Miles Wilkins book

20. Tighten caps evenly and then torque (9 lbs)

21. Put exhaust sprocket on exhaust camshaft

22 Place exhaust camshaft in head and line up timing mark to top of head Cam lobe on #4 just rocking ? see picture in Miles Wilkins book

23. Tighten caps evenly and then torque (9 lbs)

24. Remove inlet and exhaust sprockets

25. Fish up timing chain

26. Attach timing chain to inlet sprocket and then place on camshaft. Make sure timing marks are correct.

27. Attach timing chain to exhaust sprocket and then place on cam. May have to use vice grip on camshaft to move slightly to make sure timing marks are correct.

28. Install timing chain tensioner in block and adjust timing chain.

29. Rotate engine at least 2 times and make sure timing marks line up

30. Torque camshaft sprocket bolts and front pulley bolt to 25 lbs

Alternative per Miles Wilkins is to start with exhaust sprocket. Starting with inlet is per Elan website.

Do not turn camshafts without timing chain attached (can turn only a minimal amount) Valves can hit if turn.

Per number #5 above is Loctite correct in this location?

Is it correct that the Europa inlet camshaft is sealed by the alternator pulley bolt. Should Permatex sealant be used on this bolt?

- Britcar82

- New-tral

- Posts: 8

- Joined: 15 Nov 2018

I must say I have not cheked the whole list, but regarding #3 TDC finding I would use the first version BUT only turning clockwise, so as not to mess alignments with the slack of the chain. I understand you may be able to cut corners being very careful and if you don't have a lot of slack in the chain by going over CCW and backing to take up the slack CW before your measurement, but the option of turning only CW is bullet proof.

--edit oups got the rotation upside down at first ... time to call it a day

--edit oups got the rotation upside down at first ... time to call it a day

Last edited by nmauduit on Fri Nov 16, 2018 10:15 pm, edited 1 time in total.

S4SE 36/8198

-

nmauduit - Coveted Fifth Gear

- Posts: 2045

- Joined: 02 Sep 2013

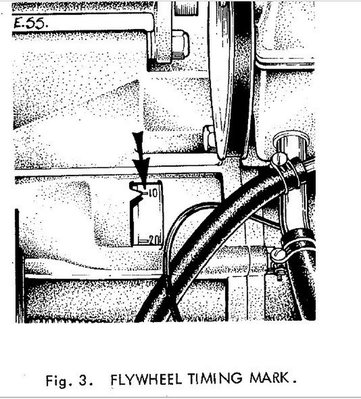

Also I have not read the whole list (so I am lazy) but the Europa TC has the timing marks on the flywheel (seen through a slot in the bellhousing from above)TDC and advance marks can be found from there.

Probably not good enough for exact degree timing set up but certainly good enough to set up the engine initially.

Not sure if the pulley marks can be seen from below, I have had both a Renault and TC Special Europa's but saw the light and changed to Elans

Probably not good enough for exact degree timing set up but certainly good enough to set up the engine initially.

Not sure if the pulley marks can be seen from below, I have had both a Renault and TC Special Europa's but saw the light and changed to Elans

Brian

64 S2 Roadster

72 Sprint FHC

64 S2 Roadster

72 Sprint FHC

-

types26/36 - Coveted Fifth Gear

- Posts: 3873

- Joined: 11 Sep 2003

This was my description of how to fit the cylinder head and cam sprockets on a twin-can.

lotus-twincam-f39/clay-test-checking-clearance-between-valves-pistons-t26441.html#p175063

It's important to ensure that the portion of the chain from the crankshaft pulley to the output valves sprocket is taut. at all times.

Your measurement of TDC seems over fussy to me, with the head off, its pretty obvious where TDC is, its when the piston in cyl 1 reaches the top and starts to go down.

lotus-twincam-f39/clay-test-checking-clearance-between-valves-pistons-t26441.html#p175063

It's important to ensure that the portion of the chain from the crankshaft pulley to the output valves sprocket is taut. at all times.

Your measurement of TDC seems over fussy to me, with the head off, its pretty obvious where TDC is, its when the piston in cyl 1 reaches the top and starts to go down.

Bill Williams

36/6725 S3 Coupe OGU108E Yellow over Black.

36/6725 S3 Coupe OGU108E Yellow over Black.

- billwill

- Coveted Fifth Gear

- Posts: 5062

- Joined: 19 Apr 2008

Thanks to everyone. I've only built one engine before this (an MG) so I'm trying to dot all of my i's and cross all of my t's.

Bill, Timing chain idler, I meant timing chain sprocket. Before I decided to make my list I had read another post about someone snapping a camshaft. I don't want to do that or bend a valve so I'm trying to be extra careful.

Thank you for the link. Your pictures and write up will be a great help.

I don't have the gearbox/bell housing at the moment. It's at a shop being rebuilt. The engine is currently on a stand.

Thanks again,

Sherman

Bill, Timing chain idler, I meant timing chain sprocket. Before I decided to make my list I had read another post about someone snapping a camshaft. I don't want to do that or bend a valve so I'm trying to be extra careful.

Thank you for the link. Your pictures and write up will be a great help.

I don't have the gearbox/bell housing at the moment. It's at a shop being rebuilt. The engine is currently on a stand.

Thanks again,

Sherman

- Britcar82

- New-tral

- Posts: 8

- Joined: 15 Nov 2018

In the past I've used the positive stop method for finding TDC, but this was only for dialling in cams once it was all together and not for installing the head. As others have said it's pretty obvious when the head is off where TDC is.

Chris

Elan +2 #0245

Exige S2 Supercharged

Elan +2 #0245

Exige S2 Supercharged

- Chrispy

- Third Gear

- Posts: 331

- Joined: 29 Oct 2017

7 posts

• Page 1 of 1

Total Online:

Users browsing this forum: No registered users and 21 guests