Piston / combustion chamber damage

20 posts

• Page 1 of 2 • 1, 2

Hi, I've been lurking around here for a few years but this is my first post so please be gentle!

Bit of a long story but please stick with it!

So, I've been attempting to recommission a 1968 Elan S4 that has been in our family for around 15 years.

This car has had a rather chequered history.

It was purchased as a box of bits with a rotten chassis and a body showing some crash damage.

It underwent a large amount of work in 1999/2000 which included a new galvanised chassis and running gear. The body was repaired and re-sprayed and the wiring and interior was also replaced.

The engine was thought to have recently undergone a rebuild, so along with the gearbox was installed in the new chassis where it was started and ran well.

Due to a number of reasons the work then ground to a halt and the car was stored in various garages and also, for a time, under cover outside. It has now found its way into my garage where I had begun the process of finishing off the work and getting it back on the road.

The engine was started for the first time in 10 years and the car was driveable.

I then discovered a huge oil leak from the back of the gearbox and so the decision was made to remove it have it reconditioned.

Whilst it was out I decided look at the condition of the engine. The head was removed with a view to changing the water pump and perhaps having new guides and seats fitted to allow the use of unleaded fuel.

This brings us up to date. Upon removal of the head I've discovered some damage to the no.3 piston and the corresponding combustion chamber. I've attached some pictures of the damage and would like some opinions on what may have caused this damage and whether or not the head is repairable.

There is also a picture of some scoring in cylinder no.1.

I think I've almost convinced myself to perform a complete rebuild but the damage to the head bothers me!

Any help would be gratefully received.

Thanks in advance!

Paul

Bit of a long story but please stick with it!

So, I've been attempting to recommission a 1968 Elan S4 that has been in our family for around 15 years.

This car has had a rather chequered history.

It was purchased as a box of bits with a rotten chassis and a body showing some crash damage.

It underwent a large amount of work in 1999/2000 which included a new galvanised chassis and running gear. The body was repaired and re-sprayed and the wiring and interior was also replaced.

The engine was thought to have recently undergone a rebuild, so along with the gearbox was installed in the new chassis where it was started and ran well.

Due to a number of reasons the work then ground to a halt and the car was stored in various garages and also, for a time, under cover outside. It has now found its way into my garage where I had begun the process of finishing off the work and getting it back on the road.

The engine was started for the first time in 10 years and the car was driveable.

I then discovered a huge oil leak from the back of the gearbox and so the decision was made to remove it have it reconditioned.

Whilst it was out I decided look at the condition of the engine. The head was removed with a view to changing the water pump and perhaps having new guides and seats fitted to allow the use of unleaded fuel.

This brings us up to date. Upon removal of the head I've discovered some damage to the no.3 piston and the corresponding combustion chamber. I've attached some pictures of the damage and would like some opinions on what may have caused this damage and whether or not the head is repairable.

There is also a picture of some scoring in cylinder no.1.

I think I've almost convinced myself to perform a complete rebuild but the damage to the head bothers me!

Any help would be gratefully received.

Thanks in advance!

Paul

- PaulFinch

- Second Gear

- Posts: 93

- Joined: 09 Oct 2012

Looks like a bolt or something similar went through the cylinder. It looks lucky you only have a couple of dings in the head. I presume there is matching ding in the piston for the head ding near the exhaust valve as well. The are a couple of marks in the piston valve pocket which may mean the item was laso jammed between the valve and piston. I would certainly replace the valves and piston in this cylinder and check the rod and bearings closely as the high loads caused the item jamming between the head and piston could have caused damege.

The head itself is probably OK and can easily be repair welded.

cheers

Rohan

The head itself is probably OK and can easily be repair welded.

cheers

Rohan

-

rgh0 - Coveted Fifth Gear

- Posts: 8831

- Joined: 22 Sep 2003

Thanks Rohan,

My initial thought was something sucked in to the bore. I just can't bring myself to believe I've allowed something that stupid to happen!

Yes, there is a corresponding ding on the exhaust side of the piston. I think a full engine strip may be on the cards.

I assume welding damage like this should be left to engineering companies who have dealt with twin cams in the past.

Anyone have any recommendations for such an establishment in the UK?

Paul

My initial thought was something sucked in to the bore. I just can't bring myself to believe I've allowed something that stupid to happen!

Yes, there is a corresponding ding on the exhaust side of the piston. I think a full engine strip may be on the cards.

I assume welding damage like this should be left to engineering companies who have dealt with twin cams in the past.

Anyone have any recommendations for such an establishment in the UK?

Paul

- PaulFinch

- Second Gear

- Posts: 93

- Joined: 09 Oct 2012

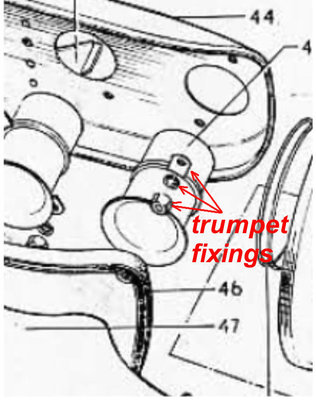

Could one of the trumpet fixings have been ingested at some point?

(Some have used an alternative & safer arrangement but can't find the detail at the moment...)

Cheers - Richard

(Some have used an alternative & safer arrangement but can't find the detail at the moment...)

Cheers - Richard

- ardee_selby

- Coveted Fifth Gear

- Posts: 2197

- Joined: 30 Sep 2003

well in the list of stupid things IVe done ...1 using an old cheap screw diver to check TDC and when withdrawn half of the damaged tip stayed in......result welding the port new valves and piston in #1 cylinder 2 allowing a spark Plug lead screw fitting fall into the head. While changing plugs ...The shape of your damage resembles that plug end so you may have bought the engine in that shape ....I caught that one resulted in pullingthehead and a new gasket ona nice sunny drive day .dum de dum dum....if you don't put. Tape or plug the spark plug hole immediately these things happen ....ed

dont close your eyes --you will miss the crash

Editor: On June 12, 2020, Edward Law, AKA TwinCamMan, passed away; his obituary can be read at https://www.friscolanti.com/obituary/edward-law. He will be missed.

Editor: On June 12, 2020, Edward Law, AKA TwinCamMan, passed away; his obituary can be read at https://www.friscolanti.com/obituary/edward-law. He will be missed.

-

twincamman - Coveted Fifth Gear

- Posts: 3175

- Joined: 02 Oct 2003

Ad anothe Dummy (me) to the list.

Wanted tocehck where real TDC was last night as I had suspected thst pully mark may have been out br 10 degrees.

Pulled the plug on one and spotted a piece of rubber or plastic (wire and casing) about 5mm long on the edge of the plug hole.

So what did I do??

Put the plug back and get a vacuum cleaner?? No. Get something stiocky to pick it up? No

I tried to pick it up with my fingers, when that didn't work I got a long nosed pliers and promptly knocked it into the bore.

Tried to vacuum it out with some tubing in the bore taped onto a vacuum cleaner but am not sure if it's out.

Luckily a friend has a bore scope....so fingers crossed....

Oh! TDC seems to be spot on the TDC mark on the pulley....which means my timing is WAY too advanced....

Peter

Wanted tocehck where real TDC was last night as I had suspected thst pully mark may have been out br 10 degrees.

Pulled the plug on one and spotted a piece of rubber or plastic (wire and casing) about 5mm long on the edge of the plug hole.

So what did I do??

Put the plug back and get a vacuum cleaner?? No. Get something stiocky to pick it up? No

I tried to pick it up with my fingers, when that didn't work I got a long nosed pliers and promptly knocked it into the bore.

Tried to vacuum it out with some tubing in the bore taped onto a vacuum cleaner but am not sure if it's out.

Luckily a friend has a bore scope....so fingers crossed....

Oh! TDC seems to be spot on the TDC mark on the pulley....which means my timing is WAY too advanced....

Peter

I is an Inginear....please excuse my speeling!

'73 +2S 130/5

Scimitar GTE for the lazy days, 3008, Some bicycles, Wife, Kids, Cats, Dogs....chickens....cluck cluck...one duck...the others flew away!

'73 +2S 130/5

Scimitar GTE for the lazy days, 3008, Some bicycles, Wife, Kids, Cats, Dogs....chickens....cluck cluck...one duck...the others flew away!

-

peterako - Fourth Gear

- Posts: 699

- Joined: 02 Mar 2006

Welcome!

Those look like hone marks in pic 1 - Much too even for FOD

Pic 3 the indent seems to below the edge of the valve is there any damage to the valve or seat?

My guess is that you are looking at old scars and the engine has been rebuilt?

Why do you need to replace guides and seats? it burnt oil? the tappets were noisy? ...Not for unleaded!

did the water pump leak or squeak?

If it ran well why do you want to rebuild it? it will cost you ?2k.

Gearbox oil leak can be cured with a seal kit for ?10 - why have it rebuilt? Take the cover off and have a look at the condition! Check the propshaft welch plug.

If you want to get the car on the road you are going in the wrong direction!

Those look like hone marks in pic 1 - Much too even for FOD

Pic 3 the indent seems to below the edge of the valve is there any damage to the valve or seat?

My guess is that you are looking at old scars and the engine has been rebuilt?

Why do you need to replace guides and seats? it burnt oil? the tappets were noisy? ...Not for unleaded!

did the water pump leak or squeak?

If it ran well why do you want to rebuild it? it will cost you ?2k.

Gearbox oil leak can be cured with a seal kit for ?10 - why have it rebuilt? Take the cover off and have a look at the condition! Check the propshaft welch plug.

If you want to get the car on the road you are going in the wrong direction!

- AHM

- Coveted Fifth Gear

- Posts: 1453

- Joined: 19 Apr 2004

Thanks for all your replies.

AHM - The main reason for thinking about a rebuild is because of all the uncertainty surrounding the engine.

When I say 'it ran well' I mean it started ok and revved freely, I have only ever driven the car up and down the cul de sac so have no idea about its true condition (oil consumption, behaviour under load etc).

Like I said, the car was a box of bits 13 years ago and, from what I understand, had been in this state for at least 10 years before this.

If these are old scars and the engine has been rebuilt then it wasn't rebuilt very well. I wouldn't put an engine back together with that amount of visible damage, and if that is the case and someone has rebuilt it in this state then I'm worried about what else they might have ignored.

You say I am going in the wrong direction but I don't see it like that. The engine, of unknown history and condition, which has sat for at least 20 years without any real use, is out of the car and now would seem like the perfect time for it to undergo refurbishment. This will give me peace of mind and hopefully an engine that, when well maintained, won't need any serious work for the next 50,000 miles / 5 years.

The same is true with regards to the gearbox. As I don't know whether it was making any strange noises or experiencing any other issues I think it would be foolish to assume that it's in A one condition, put it back in the car only to find in 1000 miles time that the bearings collapse or a synchro wears out. I have taken the inspection cover off and there is little visible wear but it's no guarantee of overall condition.

My aim is to have a useable and reliable Elan that I can drive and enjoy. I don't think I'd be able to do that with the engine and gearbox in their current state. I think I will gain far more enjoyment from knowing the car is 'right' but having to wait a few months to get it on the road, rather than just bolting it back together and getting it MOT'd next week.

Thanks again,

Paul

AHM - The main reason for thinking about a rebuild is because of all the uncertainty surrounding the engine.

When I say 'it ran well' I mean it started ok and revved freely, I have only ever driven the car up and down the cul de sac so have no idea about its true condition (oil consumption, behaviour under load etc).

Like I said, the car was a box of bits 13 years ago and, from what I understand, had been in this state for at least 10 years before this.

If these are old scars and the engine has been rebuilt then it wasn't rebuilt very well. I wouldn't put an engine back together with that amount of visible damage, and if that is the case and someone has rebuilt it in this state then I'm worried about what else they might have ignored.

You say I am going in the wrong direction but I don't see it like that. The engine, of unknown history and condition, which has sat for at least 20 years without any real use, is out of the car and now would seem like the perfect time for it to undergo refurbishment. This will give me peace of mind and hopefully an engine that, when well maintained, won't need any serious work for the next 50,000 miles / 5 years.

The same is true with regards to the gearbox. As I don't know whether it was making any strange noises or experiencing any other issues I think it would be foolish to assume that it's in A one condition, put it back in the car only to find in 1000 miles time that the bearings collapse or a synchro wears out. I have taken the inspection cover off and there is little visible wear but it's no guarantee of overall condition.

My aim is to have a useable and reliable Elan that I can drive and enjoy. I don't think I'd be able to do that with the engine and gearbox in their current state. I think I will gain far more enjoyment from knowing the car is 'right' but having to wait a few months to get it on the road, rather than just bolting it back together and getting it MOT'd next week.

Thanks again,

Paul

- PaulFinch

- Second Gear

- Posts: 93

- Joined: 09 Oct 2012

Paul,

Your car, your time, your money, your comments.

Why do you say it hasn't been rebuilt very well? That isn't much damage, and what benefit will filling the dents with weld have? Take it to a machine shop and see what they say.

You can check the condition of the bearings by undoing a few bolts.

Don't forget, this is 60's engineering so looking at it now you wouldn't put it together in the state in which it was new.

Realistically you aren't going to get it MOT'd next year let alone next week.

Simon

Your car, your time, your money, your comments.

Why do you say it hasn't been rebuilt very well? That isn't much damage, and what benefit will filling the dents with weld have? Take it to a machine shop and see what they say.

You can check the condition of the bearings by undoing a few bolts.

Don't forget, this is 60's engineering so looking at it now you wouldn't put it together in the state in which it was new.

Realistically you aren't going to get it MOT'd next year let alone next week.

Simon

- AHM

- Coveted Fifth Gear

- Posts: 1453

- Joined: 19 Apr 2004

Simon,

I say it hasn't been rebuilt very well because the piston and combustion chambers have visible damage. These are two fairly critical areas in any engine.

Repairing the combustion chamber will mean that the squish area isn't adversely affected and ensure that combustion takes place as it was intended. Combustion chambers are the shape they are for a reason, it's not just guess work.

Any damage to a piston will be a potential weak point and I don't really like the idea of writing off my engine when it lets go at 6500rpm. It's happened to me before and was not an enjoyable experience.

Thank you so much for your informative, useful and overall motivational advice.

I'm pleased that you know so much about me, my car and my circumstances that you are able to tell me when it's likely to be on the road.

Friendly round here, isn't it.

I say it hasn't been rebuilt very well because the piston and combustion chambers have visible damage. These are two fairly critical areas in any engine.

Repairing the combustion chamber will mean that the squish area isn't adversely affected and ensure that combustion takes place as it was intended. Combustion chambers are the shape they are for a reason, it's not just guess work.

Any damage to a piston will be a potential weak point and I don't really like the idea of writing off my engine when it lets go at 6500rpm. It's happened to me before and was not an enjoyable experience.

Thank you so much for your informative, useful and overall motivational advice.

I'm pleased that you know so much about me, my car and my circumstances that you are able to tell me when it's likely to be on the road.

Friendly round here, isn't it.

- PaulFinch

- Second Gear

- Posts: 93

- Joined: 09 Oct 2012

Hi Paul,

I would pull the gearbox apart if it has been sat about. You may have seen my post, perhaps, about opening boxes and finding damage with the roller bearings between the first motion shaft and the main shaft. My eyes are opened and having just put it all back together with new seals and bearing etc I am now happy. I will be opening up some older ones that I have this weekend to see what can be salvaged for my spares pot. I have few ford 3 rail boxes with the same main shaft as some of the early semi close boxes (pre snap ring type -draw nut).

Re: engine. As you will know they are worth a bob or two. If your gut says pull it, do it. I am happy to spilt stuff and find it in good condition. Not wasted time. I do not worry then. I know it is right. You can find all sorts of old bollocks jobs on cars that you thought were to a standard across the board. I found some good stuff on a car I bought from a well known whizzy club guy. Front callipers hanging on short bolts by a few threads. Rushed last part of a restoration. I was lucky that I did not launch them. Rest of car was generally good.

No price on peace of mind.

Part of the hobby, for me, is everything ?the scene?, ?the people?, research, buying bits, garage work and driving.

Mike

I would pull the gearbox apart if it has been sat about. You may have seen my post, perhaps, about opening boxes and finding damage with the roller bearings between the first motion shaft and the main shaft. My eyes are opened and having just put it all back together with new seals and bearing etc I am now happy. I will be opening up some older ones that I have this weekend to see what can be salvaged for my spares pot. I have few ford 3 rail boxes with the same main shaft as some of the early semi close boxes (pre snap ring type -draw nut).

Re: engine. As you will know they are worth a bob or two. If your gut says pull it, do it. I am happy to spilt stuff and find it in good condition. Not wasted time. I do not worry then. I know it is right. You can find all sorts of old bollocks jobs on cars that you thought were to a standard across the board. I found some good stuff on a car I bought from a well known whizzy club guy. Front callipers hanging on short bolts by a few threads. Rushed last part of a restoration. I was lucky that I did not launch them. Rest of car was generally good.

No price on peace of mind.

Part of the hobby, for me, is everything ?the scene?, ?the people?, research, buying bits, garage work and driving.

Mike

Last edited by miked on Fri Oct 12, 2012 8:32 am, edited 1 time in total.

Mike

Elan S4 Zetec

Suzuki Hustler T250

Suzuki TC120R trailcat

Yamaha YR5

Suzuki Vstrom 650XT

Suzuki TS185K

Elan S4 Zetec

Suzuki Hustler T250

Suzuki TC120R trailcat

Yamaha YR5

Suzuki Vstrom 650XT

Suzuki TS185K

-

miked - Coveted Fifth Gear

- Posts: 1233

- Joined: 29 Sep 2003

PaulFinch wrote:Hi, I've been lurking around here for a few years but this is my first post so please be gentle!

Paul

Paul,

Welcome to LotusElan.net, please don't be put off by any perceived abuse or what you feel are cantankerous replies, these forums are in my experience the most gentlemanly and overall helpful resource you will find anywhere. Sometimes this site is a victim of it's own success in that you can post a question and almost immediately get 3 or 4 conflicting replies from well meaning participants, all the advice here is free and freely given. Simon took the time and effort to reply and expressed his opinion, I'm sure it was well intentioned.

The damage that is shown on your pictures looks serious enough to me for you to at least investigate it further, Rohan's advice is seriously worth considering.

Kindest regards

Kindest regards

Alan Thomas

Alan Thomas

-

Spyder fan - Coveted Fifth Gear

- Posts: 2845

- Joined: 11 Jun 2009

personally I would leave the head alone, trying to build it up with weld could cause far more serious problems (distortion & porosity), just clean up around the damage to remove any potenital pre-ignition sites and check the valve seats and valves for damage.

It does look like it has been honed very recently, in which case I would pull the piston and rod and get the rod checked for distortion (twisting and roundness of both big and little ends) and if all is OK re-build with a new piston.

It does look like it has been honed very recently, in which case I would pull the piston and rod and get the rod checked for distortion (twisting and roundness of both big and little ends) and if all is OK re-build with a new piston.

- kstrutt11

- Third Gear

- Posts: 427

- Joined: 27 Jun 2007

Paul,

I'm sorry that you have taken exception to my opinion. Although I believe you offered an open invitation for opinions.

You are correct I know nothing about you - My throw away comment was in response to yours!

If you disagree wih my opionion or advice that is fine. I try to offer factual advice, if however, you have already "convinced myself to perform a complete rebuild" and disagree please save your sarcasm.

Personally, for peace of mind, I would have stripped and rebuilt the engine before running it. Regarding the quality of the rebuild, from what you say you know little of it. What Pistons were available to the rebuilder, what did they have crack tested or straightened? You won?t be mixing forged and cast pistons with different rings will you? A new set of pistons could be ?500 and the head work another ?500 ? My ?2k is looking a little light! Sorry if you don?t find that motivating!

I invite you to objectively re-read my posts. Have I not offered realistic opinion, factual advice, and alerted you to some key points/alternatives? I could have just said read the archives .... Where you will find much information. Particularly you may like to reference discussion on porous/soft heads, the cost of an engine rebuild, and missing Welch plugs.

It is easy to misinterpret the emphasis of the written word on forum, as you seem to have mine. The sarcasm and patronising comment in your last post are however clear.

Regarding friendliness. It is pretty friendly around here. You seem to have overlooked that my opening word was Welcome, and rather ungratefully dismissed the donation of my time.

Indeed, (no CFD packages then) not just guess work, there was a lot of trial and error as well, and the design of the twincam combustion chamber had moved on considerably from squish as the primary means of controlling flame speed. So for the small dents that you have, if you polish the tits off to prevent hot spots on your head, it will likely have naff all effect.

Regards,

Simon

I'm sorry that you have taken exception to my opinion. Although I believe you offered an open invitation for opinions.

You are correct I know nothing about you - My throw away comment was in response to yours!

PaulFinch wrote: .... rather than just bolting it back together and getting it MOT'd next week.

PaulFinch wrote:Thank you so much for your informative, useful and overall motivational advice.

If you disagree wih my opionion or advice that is fine. I try to offer factual advice, if however, you have already "convinced myself to perform a complete rebuild" and disagree please save your sarcasm.

Personally, for peace of mind, I would have stripped and rebuilt the engine before running it. Regarding the quality of the rebuild, from what you say you know little of it. What Pistons were available to the rebuilder, what did they have crack tested or straightened? You won?t be mixing forged and cast pistons with different rings will you? A new set of pistons could be ?500 and the head work another ?500 ? My ?2k is looking a little light! Sorry if you don?t find that motivating!

I invite you to objectively re-read my posts. Have I not offered realistic opinion, factual advice, and alerted you to some key points/alternatives? I could have just said read the archives .... Where you will find much information. Particularly you may like to reference discussion on porous/soft heads, the cost of an engine rebuild, and missing Welch plugs.

It is easy to misinterpret the emphasis of the written word on forum, as you seem to have mine. The sarcasm and patronising comment in your last post are however clear.

Regarding friendliness. It is pretty friendly around here. You seem to have overlooked that my opening word was Welcome, and rather ungratefully dismissed the donation of my time.

PaulFinch wrote:Repairing the combustion chamber will mean that the squish area isn't adversely affected and ensure that combustion takes place as it was intended. Combustion chambers are the shape they are for a reason, it's not just guess work.

Indeed, (no CFD packages then) not just guess work, there was a lot of trial and error as well, and the design of the twincam combustion chamber had moved on considerably from squish as the primary means of controlling flame speed. So for the small dents that you have, if you polish the tits off to prevent hot spots on your head, it will likely have naff all effect.

Regards,

Simon

- AHM

- Coveted Fifth Gear

- Posts: 1453

- Joined: 19 Apr 2004

Just to prove that this is a friendly forum, I'll continue with my helpful, if not inspiring or motivating advice

On the plus side it looks like there has been little head skimming so far.

Check the shim thickness for each valve ? will tell you the state of the seat

You are not going to get away with welding the ding by the inlet valve without removing the seat and having the recess recut.

Now I know that you want to fit new valve guides, valves, and seats, but have you had a quote yet? The classic car community is still divided on the need for hardened inserts for unleaded, particularly where already hard seats are used in aluminium heads ? I think the consensus here was that it wasn?t needed (all those that want to discuss please start a new thread).

And have you seen the price and disclaimers that go with welding old aluminium heads. (you won?t get a price until the job is done)

For reference a similar head job, with welding on the inlet manifold lug (but without recutting the valve seat recess) was ?600 +VAT +Valves ?150 ish

Pistons

New set of forged pistons ?500. Cast no longer available and some of them have obscure unavailable rings. Unless you are still on standard bore size when Original Lotus pistons can be had from Miles Wilkins for a sensible price. However, you have large valve cut-outs and Miles? are small so you can?t buy just one. So if you have standard size A type pistons and are stuck for one I may be able to help you!

On the plus side it looks like there has been little head skimming so far.

Check the shim thickness for each valve ? will tell you the state of the seat

You are not going to get away with welding the ding by the inlet valve without removing the seat and having the recess recut.

Now I know that you want to fit new valve guides, valves, and seats, but have you had a quote yet? The classic car community is still divided on the need for hardened inserts for unleaded, particularly where already hard seats are used in aluminium heads ? I think the consensus here was that it wasn?t needed (all those that want to discuss please start a new thread).

And have you seen the price and disclaimers that go with welding old aluminium heads. (you won?t get a price until the job is done)

For reference a similar head job, with welding on the inlet manifold lug (but without recutting the valve seat recess) was ?600 +VAT +Valves ?150 ish

Pistons

New set of forged pistons ?500. Cast no longer available and some of them have obscure unavailable rings. Unless you are still on standard bore size when Original Lotus pistons can be had from Miles Wilkins for a sensible price. However, you have large valve cut-outs and Miles? are small so you can?t buy just one. So if you have standard size A type pistons and are stuck for one I may be able to help you!

- AHM

- Coveted Fifth Gear

- Posts: 1453

- Joined: 19 Apr 2004

20 posts

• Page 1 of 2 • 1, 2

Total Online:

Users browsing this forum: pdenton26, steve lyle, Tmac897 and 36 guests