S1 Elan Rebuild - My Story

Got my new rear rotors from TTR and installed them on the drive train. The rotor holes lined up perfectly with the half shafts and axle shafts. Did the left side first, all went well. Then moved to the right side and had a couple of issues. First the caps of the studs wouldn't fit past the only area on the bearing carrier allows them to slide thru. Had to tap them in with a small hammer. OK, no big deal. Then after I install all three bolts and rotate the hub notice one of the caps ever so slightly hits the bearing carrier. After a couple of rotations everything is fine, but I am a bit concerned about the close tolerance. See photos below. Any comments to this or is it just the abnormally of an old casting?

Got everything together and started rotating the hubs. Left side rotates fine. I try the right side, its makes one revolution and binds. Odd, I thought. Look for where it is binding and cant seem to find anything. All of a sudden I remember reading a post about the Ujoint drive shafts binding if the suspension is drooping. I lower the chassis to the ground and roll it back and forth in the garage. No binding.

Got everything together and started rotating the hubs. Left side rotates fine. I try the right side, its makes one revolution and binds. Odd, I thought. Look for where it is binding and cant seem to find anything. All of a sudden I remember reading a post about the Ujoint drive shafts binding if the suspension is drooping. I lower the chassis to the ground and roll it back and forth in the garage. No binding.

Last edited by Certified Lotus on Sat Jun 13, 2015 11:07 am, edited 1 time in total.

Glen

05 Elise - Back where I started

65 Elan S2 - 26/4055

72 Europa - 74/2358R

69 Elan S4 - 45/7941

64 Elan S1 - 26/0379

12 Colin 30 - Lotus Racing Kart

07 Exige S - Wicked Road/Track Car

07 Exige S - Fast Road/Track Car

06 Elise - Track pack

05 Elise - Back where I started

65 Elan S2 - 26/4055

72 Europa - 74/2358R

69 Elan S4 - 45/7941

64 Elan S1 - 26/0379

12 Colin 30 - Lotus Racing Kart

07 Exige S - Wicked Road/Track Car

07 Exige S - Fast Road/Track Car

06 Elise - Track pack

-

Certified Lotus - Coveted Fifth Gear

- Posts: 1233

- Joined: 04 Aug 2014

I have the same shafts I believe: I found on the large dia. side of the shaft the angular travel is restricted in one direction by interference of the clevice to the centre, a bit of careful material removal will improve travel several degrees but not to the same extent of the small end. If you set them on the bench and measure the angles in both directions on both ends you should see what I am talking about. (I bought mine about 4 years ago). While some will say it makes no difference which way around you put the shafts, in fact it does, as the camber change of the wheel at full droop is favourable to the angle interference of the shaft, so it works better if you put the large dia. to the outboard side, opposite to your pict. Believe me I had mine on and off at least three times sorting out the interference and differences! You may need to add travel restrictors, however I didn't have to.

Jack

Jack

- jk952

- Third Gear

- Posts: 304

- Joined: 04 Jan 2011

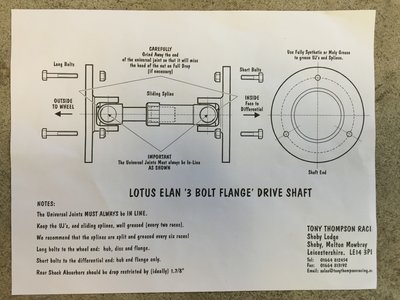

Jack, the axle shafts came with very specific instructions (see below). Did you have the same on yours when you installed them?

I have the limited droop Koni shocks that are special order from TTR so no need to restrict anything.

I have the limited droop Koni shocks that are special order from TTR so no need to restrict anything.

Glen

05 Elise - Back where I started

65 Elan S2 - 26/4055

72 Europa - 74/2358R

69 Elan S4 - 45/7941

64 Elan S1 - 26/0379

12 Colin 30 - Lotus Racing Kart

07 Exige S - Wicked Road/Track Car

07 Exige S - Fast Road/Track Car

06 Elise - Track pack

05 Elise - Back where I started

65 Elan S2 - 26/4055

72 Europa - 74/2358R

69 Elan S4 - 45/7941

64 Elan S1 - 26/0379

12 Colin 30 - Lotus Racing Kart

07 Exige S - Wicked Road/Track Car

07 Exige S - Fast Road/Track Car

06 Elise - Track pack

-

Certified Lotus - Coveted Fifth Gear

- Posts: 1233

- Joined: 04 Aug 2014

No unfortunately no instructions came with mine, and I can't read the scan, I will pm my email address as I wouldn't mind reading them, I am curious indeed.

As I said I tried them that way first and found the interference, there was about ten deg. less travel on one side of the one end, managed to it get to about 5 deg.

Jack

As I said I tried them that way first and found the interference, there was about ten deg. less travel on one side of the one end, managed to it get to about 5 deg.

Jack

- jk952

- Third Gear

- Posts: 304

- Joined: 04 Jan 2011

Jack, emailed you a PDF of the instruction sheet.

Spent some more time understanding the TTR ujoint drive shaft system. Jacked up the back of the chassis and slowly watched each moving part while rotating the rear wheels. With the help of my friend Drew we located the reason why the right side was binding at almost one revolution........one of the ujoint castings was just a little bit larger that the others and was hitting. Remember this is under full droop so the possibility of something happening is limited, but I wanted to make sure.

After communicating with TTR (Tony and Stuart are always very responsive) found out that there are typically small variations in the castings and its not unusual to grind the offending side down a bit to insure clearance. Was told not to worry about the potential of unbalancing the shaft as the maximum rotation speed is only 2000 rpm. My air grinder came right out and solved the problem in short order.

Spent some more time understanding the TTR ujoint drive shaft system. Jacked up the back of the chassis and slowly watched each moving part while rotating the rear wheels. With the help of my friend Drew we located the reason why the right side was binding at almost one revolution........one of the ujoint castings was just a little bit larger that the others and was hitting. Remember this is under full droop so the possibility of something happening is limited, but I wanted to make sure.

After communicating with TTR (Tony and Stuart are always very responsive) found out that there are typically small variations in the castings and its not unusual to grind the offending side down a bit to insure clearance. Was told not to worry about the potential of unbalancing the shaft as the maximum rotation speed is only 2000 rpm. My air grinder came right out and solved the problem in short order.

Last edited by Certified Lotus on Sat Jun 13, 2015 11:04 am, edited 3 times in total.

Glen

05 Elise - Back where I started

65 Elan S2 - 26/4055

72 Europa - 74/2358R

69 Elan S4 - 45/7941

64 Elan S1 - 26/0379

12 Colin 30 - Lotus Racing Kart

07 Exige S - Wicked Road/Track Car

07 Exige S - Fast Road/Track Car

06 Elise - Track pack

05 Elise - Back where I started

65 Elan S2 - 26/4055

72 Europa - 74/2358R

69 Elan S4 - 45/7941

64 Elan S1 - 26/0379

12 Colin 30 - Lotus Racing Kart

07 Exige S - Wicked Road/Track Car

07 Exige S - Fast Road/Track Car

06 Elise - Track pack

-

Certified Lotus - Coveted Fifth Gear

- Posts: 1233

- Joined: 04 Aug 2014

As my engine still isn't done...... I've got time to finish the installation of the brake system (got my 5-way brake tube junction) and reinstall the parking brake with a new cable.

Started cleaning up the transmission inside the bell housing as lots of clutch dust mixed with trans oil that had been leaking for a while. I had already ordered new seals front and rear and while getting ready to pull the seals noticed the input shaft on the trans was pretty sloppy. Checked the outer bearing for damage, it looked ok. Opened the shop manual to see the exploded view of the trans and noted the location of the needle bearing. Mmmmmm, that could be the culprit. Well, I have the trans out, the engines not done, maybe time to replace all the bearings in the trans (The PO had the trans rebuilt in 1984). Made a quick call to RD Enterprises, Ray had all the bearings and shipped them to me overnight. Guess what I'm doing tomorrow?

Started cleaning up the transmission inside the bell housing as lots of clutch dust mixed with trans oil that had been leaking for a while. I had already ordered new seals front and rear and while getting ready to pull the seals noticed the input shaft on the trans was pretty sloppy. Checked the outer bearing for damage, it looked ok. Opened the shop manual to see the exploded view of the trans and noted the location of the needle bearing. Mmmmmm, that could be the culprit. Well, I have the trans out, the engines not done, maybe time to replace all the bearings in the trans (The PO had the trans rebuilt in 1984). Made a quick call to RD Enterprises, Ray had all the bearings and shipped them to me overnight. Guess what I'm doing tomorrow?

Last edited by Certified Lotus on Sat Jun 13, 2015 2:24 pm, edited 1 time in total.

Glen

05 Elise - Back where I started

65 Elan S2 - 26/4055

72 Europa - 74/2358R

69 Elan S4 - 45/7941

64 Elan S1 - 26/0379

12 Colin 30 - Lotus Racing Kart

07 Exige S - Wicked Road/Track Car

07 Exige S - Fast Road/Track Car

06 Elise - Track pack

05 Elise - Back where I started

65 Elan S2 - 26/4055

72 Europa - 74/2358R

69 Elan S4 - 45/7941

64 Elan S1 - 26/0379

12 Colin 30 - Lotus Racing Kart

07 Exige S - Wicked Road/Track Car

07 Exige S - Fast Road/Track Car

06 Elise - Track pack

-

Certified Lotus - Coveted Fifth Gear

- Posts: 1233

- Joined: 04 Aug 2014

Greg, I will be at LOG 35 but not with my Elan. Too far to drive in a small car and the transport that was being arranged here in the NE fell through. I'm flying out. I'll be the guy with a Nikon SLR and a video camera slung on my shoulder.

Here is a video I shot of LOG 33 at Watkins Glen:

https://www.youtube.com/watch?v=rpXTs59l63Y

Will you be there?

Here is a video I shot of LOG 33 at Watkins Glen:

https://www.youtube.com/watch?v=rpXTs59l63Y

Will you be there?

Glen

05 Elise - Back where I started

65 Elan S2 - 26/4055

72 Europa - 74/2358R

69 Elan S4 - 45/7941

64 Elan S1 - 26/0379

12 Colin 30 - Lotus Racing Kart

07 Exige S - Wicked Road/Track Car

07 Exige S - Fast Road/Track Car

06 Elise - Track pack

05 Elise - Back where I started

65 Elan S2 - 26/4055

72 Europa - 74/2358R

69 Elan S4 - 45/7941

64 Elan S1 - 26/0379

12 Colin 30 - Lotus Racing Kart

07 Exige S - Wicked Road/Track Car

07 Exige S - Fast Road/Track Car

06 Elise - Track pack

-

Certified Lotus - Coveted Fifth Gear

- Posts: 1233

- Joined: 04 Aug 2014

Gear box rebuild day. The bearings I ordered arrived from RD Enterprises right on time (I had already ordered a complete gasket kit and the two oil seals). I headed over to Drew's shop (he has more tools & is better equipped than my shop) where he already had the gear box. Classic Drew, he had everything laid out and plastic down on a work bench to dismantle the gear box. We both had read the workshop manual and reviewed the exploded view of parts a number of times.

The question I posted on this forum about replacing the bearings got minimal response but two people brought up using a dummy shaft to remove and install the lay shaft. A couple of people said to leave the gear box alone. Thought about this a number of times, don't touch it, but the input shaft had a lot of play in it and now was the time to install new bearings, not later on when I would have to take the trans out again. Besides, it was leaking some oil and I wanted to try and minimize that.

I'll start by saying I'm glad I ventured down this path of rebuild. The input shaft bearings were very loose and the probable reason was the large nut holding the speedometer gear and main gear box shaft was not tightened to spec. As a matter of fact, it was several turns too loose causing the shaft to move back and forth, hence the reason for the sloppy bearings. Over all the gearbox was in very good condition. All the gears looked great (was rebuilt in 1984) and the syncro's all looked good. No metal in the bottom of the box.

We dismantled everything except the reverse gear shaft. Each and every step was photographed and I'm glad we did as there were a number of times we needed to go back and refer to the photos to make sure of the location of things.

Most of the rebuild was straight forward and anyone with fine mechanical skills, patience, a good memory, the factory manual and a decent shop with a press could do this. Couple of things needed to be paid attention to: there are some very small pieces that fit in locations that aren't so obvious. Loosing them or misplacing them would be easy. The syncro's need to be assembled in a very specific way and have a number of moving parts that require detailed attention. The removal of the lay shaft went easier then we thought including replacing all the roller bearings and reinstalling the lay shaft.

At the end of the re-assembly we realized that we didn't put one of the syncro's back together properly so the entire gearbox was disassembled again (we are now very good at this) and then reassembled. Before safety wiring the shift rod bolts we went thru all the gears while turning the input shaft. Everything was functioning very smoothly and we were very proud of ourselves until 4th gear........

When we put the gear shift lever into 4th gear there was a metal to metal rubbing noise. We went over it again and again, re-read the shop manual, had fiber optic lights in the gear box trying to figure out what wasn't right. We were almost ready to disassemble the gear box again when I asked Drew for a beer. Time to think it over with a cold one. We had been at this for 7 hours and needed perspective. On the second beer we realized the steel ball detents and springs weren't installed and they would prevent the fourth gear rod from moving too far forward and not allow any metal to rub. A dry install (no gaskets with sealant) proved this right. Phew!

Cleaned all the surfaces that had gaskets, trimmed a few gaskets as they didn't quite fit, used 832 sealant on both sides and put sealant on all bolts as the go thru the gearbox and are prime for leaking. Installed the two shaft seals. All that needs to be done now is paint the entire gear box and install!

Chancer had responded in my other gearbox bearing post that you don't need a press (lotus-gearbox-f37/replacing-bearings-speed-gear-box-t34411.html). Some pin punches, drifts and cold chisels are all you need. I would say that is correct, plus some skill and patience!

The question I posted on this forum about replacing the bearings got minimal response but two people brought up using a dummy shaft to remove and install the lay shaft. A couple of people said to leave the gear box alone. Thought about this a number of times, don't touch it, but the input shaft had a lot of play in it and now was the time to install new bearings, not later on when I would have to take the trans out again. Besides, it was leaking some oil and I wanted to try and minimize that.

I'll start by saying I'm glad I ventured down this path of rebuild. The input shaft bearings were very loose and the probable reason was the large nut holding the speedometer gear and main gear box shaft was not tightened to spec. As a matter of fact, it was several turns too loose causing the shaft to move back and forth, hence the reason for the sloppy bearings. Over all the gearbox was in very good condition. All the gears looked great (was rebuilt in 1984) and the syncro's all looked good. No metal in the bottom of the box.

We dismantled everything except the reverse gear shaft. Each and every step was photographed and I'm glad we did as there were a number of times we needed to go back and refer to the photos to make sure of the location of things.

Most of the rebuild was straight forward and anyone with fine mechanical skills, patience, a good memory, the factory manual and a decent shop with a press could do this. Couple of things needed to be paid attention to: there are some very small pieces that fit in locations that aren't so obvious. Loosing them or misplacing them would be easy. The syncro's need to be assembled in a very specific way and have a number of moving parts that require detailed attention. The removal of the lay shaft went easier then we thought including replacing all the roller bearings and reinstalling the lay shaft.

At the end of the re-assembly we realized that we didn't put one of the syncro's back together properly so the entire gearbox was disassembled again (we are now very good at this) and then reassembled. Before safety wiring the shift rod bolts we went thru all the gears while turning the input shaft. Everything was functioning very smoothly and we were very proud of ourselves until 4th gear........

When we put the gear shift lever into 4th gear there was a metal to metal rubbing noise. We went over it again and again, re-read the shop manual, had fiber optic lights in the gear box trying to figure out what wasn't right. We were almost ready to disassemble the gear box again when I asked Drew for a beer. Time to think it over with a cold one. We had been at this for 7 hours and needed perspective. On the second beer we realized the steel ball detents and springs weren't installed and they would prevent the fourth gear rod from moving too far forward and not allow any metal to rub. A dry install (no gaskets with sealant) proved this right. Phew!

Cleaned all the surfaces that had gaskets, trimmed a few gaskets as they didn't quite fit, used 832 sealant on both sides and put sealant on all bolts as the go thru the gearbox and are prime for leaking. Installed the two shaft seals. All that needs to be done now is paint the entire gear box and install!

Chancer had responded in my other gearbox bearing post that you don't need a press (lotus-gearbox-f37/replacing-bearings-speed-gear-box-t34411.html). Some pin punches, drifts and cold chisels are all you need. I would say that is correct, plus some skill and patience!

Last edited by Certified Lotus on Mon Jun 15, 2015 6:36 pm, edited 4 times in total.

Glen

05 Elise - Back where I started

65 Elan S2 - 26/4055

72 Europa - 74/2358R

69 Elan S4 - 45/7941

64 Elan S1 - 26/0379

12 Colin 30 - Lotus Racing Kart

07 Exige S - Wicked Road/Track Car

07 Exige S - Fast Road/Track Car

06 Elise - Track pack

05 Elise - Back where I started

65 Elan S2 - 26/4055

72 Europa - 74/2358R

69 Elan S4 - 45/7941

64 Elan S1 - 26/0379

12 Colin 30 - Lotus Racing Kart

07 Exige S - Wicked Road/Track Car

07 Exige S - Fast Road/Track Car

06 Elise - Track pack

-

Certified Lotus - Coveted Fifth Gear

- Posts: 1233

- Joined: 04 Aug 2014

Glen

05 Elise - Back where I started

65 Elan S2 - 26/4055

72 Europa - 74/2358R

69 Elan S4 - 45/7941

64 Elan S1 - 26/0379

12 Colin 30 - Lotus Racing Kart

07 Exige S - Wicked Road/Track Car

07 Exige S - Fast Road/Track Car

06 Elise - Track pack

05 Elise - Back where I started

65 Elan S2 - 26/4055

72 Europa - 74/2358R

69 Elan S4 - 45/7941

64 Elan S1 - 26/0379

12 Colin 30 - Lotus Racing Kart

07 Exige S - Wicked Road/Track Car

07 Exige S - Fast Road/Track Car

06 Elise - Track pack

-

Certified Lotus - Coveted Fifth Gear

- Posts: 1233

- Joined: 04 Aug 2014

Got an email from my engine building shop. My engine is done! Go see it on the dyno and pick it up this week. If everything goes according to plan will install the engine next weekend.

First order of business is to drill all the chassis holes, tap a couple of the holes and have the chassis aligned with the body.

I still have a long list of things I want to do before the engine gets installed. Wonder what I'm forgetting?

First order of business is to drill all the chassis holes, tap a couple of the holes and have the chassis aligned with the body.

I still have a long list of things I want to do before the engine gets installed. Wonder what I'm forgetting?

Last edited by Certified Lotus on Sun Jun 14, 2015 12:29 pm, edited 1 time in total.

Glen

05 Elise - Back where I started

65 Elan S2 - 26/4055

72 Europa - 74/2358R

69 Elan S4 - 45/7941

64 Elan S1 - 26/0379

12 Colin 30 - Lotus Racing Kart

07 Exige S - Wicked Road/Track Car

07 Exige S - Fast Road/Track Car

06 Elise - Track pack

05 Elise - Back where I started

65 Elan S2 - 26/4055

72 Europa - 74/2358R

69 Elan S4 - 45/7941

64 Elan S1 - 26/0379

12 Colin 30 - Lotus Racing Kart

07 Exige S - Wicked Road/Track Car

07 Exige S - Fast Road/Track Car

06 Elise - Track pack

-

Certified Lotus - Coveted Fifth Gear

- Posts: 1233

- Joined: 04 Aug 2014

Ron, now that makes absolute sense! Wonder why we hadn't thought of that. Thanks!

Glen

05 Elise - Back where I started

65 Elan S2 - 26/4055

72 Europa - 74/2358R

69 Elan S4 - 45/7941

64 Elan S1 - 26/0379

12 Colin 30 - Lotus Racing Kart

07 Exige S - Wicked Road/Track Car

07 Exige S - Fast Road/Track Car

06 Elise - Track pack

05 Elise - Back where I started

65 Elan S2 - 26/4055

72 Europa - 74/2358R

69 Elan S4 - 45/7941

64 Elan S1 - 26/0379

12 Colin 30 - Lotus Racing Kart

07 Exige S - Wicked Road/Track Car

07 Exige S - Fast Road/Track Car

06 Elise - Track pack

-

Certified Lotus - Coveted Fifth Gear

- Posts: 1233

- Joined: 04 Aug 2014

Total Online:

Users browsing this forum: No registered users and 30 guests