(v) Fast Road Car

22 posts

• Page 1 of 2 • 1, 2

Famous Frank asked recently on another post about my engine build. I promised to provide information on a separate thread. But, I realize I have probably bragged enough about it on previous posts. I provide some links for the earlier posts below since the search on the forum can be a bit dodgy:

lotus-twincam-f39/engine-hot-off-the-dyno-t35851.html

lotus-elan-f19/back-the-saddle-after-years-t39920.html#p278498

elan-racing-f12/sweet-sounding-twincam-t40911.html#p286619

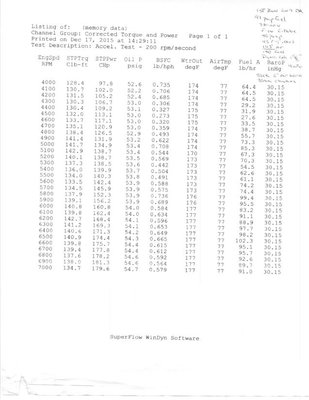

I don't think I ever posted my dyno sheet (apologies if this is a repeat):

I still only have a few hundred miles on the car since I got it back on the road. In terms of driving impressions, it is quite tractable with lots of response at lower rpms. Of course, from 4000 on up the acceleration is quite exhilarating. And handling is as good as I remember, if not better, with the wider tires (185/60 on 26r hubs/wheels).

Not really sure how fast the car is terms of timings but in impromptu stop light drags it has left everyone in the dust (haven't challenged any supercars yet).

My teenage hooligan self surfaced this last weekend. Leaving the Sears Point CSRG vintage races, and I guess inspired by the Lotus 26r I had just seen racing, I pulled away from the parking lot behind a late model Dinan modified BMW. He looked in the rear view mirror and gunned it. In terms of acceleration, my Lotus seemed more than a match. Perhaps, the turbos on the BMW take time to spool up.

Anyway, Famous Frank, if you have any other questions about my build let me know. Besides the engine, the car has been uprated throughout but with the stock outward appearance (except for wheels/tires). I have pondered messing with the body (debadging, removing "stuck-on" federal reflectors, flares, maybe 26r headlight covers) but at the moment keeping it stock. It seems that most mods come about because someone is resurrecting a damaged or badly neglected Elan. My car has never been in an accident (even has original paint) - and as original owner it would be quite painful to start cutting or otherwise messing with the body.

lotus-twincam-f39/engine-hot-off-the-dyno-t35851.html

lotus-elan-f19/back-the-saddle-after-years-t39920.html#p278498

elan-racing-f12/sweet-sounding-twincam-t40911.html#p286619

I don't think I ever posted my dyno sheet (apologies if this is a repeat):

I still only have a few hundred miles on the car since I got it back on the road. In terms of driving impressions, it is quite tractable with lots of response at lower rpms. Of course, from 4000 on up the acceleration is quite exhilarating. And handling is as good as I remember, if not better, with the wider tires (185/60 on 26r hubs/wheels).

Not really sure how fast the car is terms of timings but in impromptu stop light drags it has left everyone in the dust (haven't challenged any supercars yet).

My teenage hooligan self surfaced this last weekend. Leaving the Sears Point CSRG vintage races, and I guess inspired by the Lotus 26r I had just seen racing, I pulled away from the parking lot behind a late model Dinan modified BMW. He looked in the rear view mirror and gunned it. In terms of acceleration, my Lotus seemed more than a match. Perhaps, the turbos on the BMW take time to spool up.

Anyway, Famous Frank, if you have any other questions about my build let me know. Besides the engine, the car has been uprated throughout but with the stock outward appearance (except for wheels/tires). I have pondered messing with the body (debadging, removing "stuck-on" federal reflectors, flares, maybe 26r headlight covers) but at the moment keeping it stock. It seems that most mods come about because someone is resurrecting a damaged or badly neglected Elan. My car has never been in an accident (even has original paint) - and as original owner it would be quite painful to start cutting or otherwise messing with the body.

'69 Elan S4 SE

Street 181 BHP

Original owner

Street 181 BHP

Original owner

- 1owner69Elan

- Fourth Gear

- Posts: 897

- Joined: 16 Jun 2015

I wish I had known you and Keith Franck were coming out. I was racing my Crossle 25f in the Crossflow Cup. I had a couple extra crew passes too.

Dan

Dan

There is no cure for Lotus, only treatment.

-

StressCraxx - Coveted Fifth Gear

- Posts: 1421

- Joined: 26 Sep 2003

Dan,

We'll have to coordinate next time. Thanks for the kind offer.

We'll have to coordinate next time. Thanks for the kind offer.

'69 Elan S4 SE

Street 181 BHP

Original owner

Street 181 BHP

Original owner

- 1owner69Elan

- Fourth Gear

- Posts: 897

- Joined: 16 Jun 2015

? Kent Cams, High lift (0.44 in) , short duration, 250 deg at .050?, .008? intake and .010? exhaust cold lash. 105 lobe center on intake. 107 lobe center on exhaust.

? 1.625? intake valves, 1.375? exhaust (Manley). Stainless steel with hardchrome finish on stems

? Valve springs, US made by PSI industries

? Retainers US made VMW

? Keepers Generic 5/16? keepers

? Followers. Steel (Dave Bean)

? FF crank, square main bearing caps. Per Ford 77.6 mm stroke, shot peened and stress relieved, balanced SCCA/Scat

? Long FF Rods, 4.928? a/b centerline distance. ARP bolts

? Custom forged CP pistons, with special wrist pin heights, 3.2765? diameter, 3.2795? bore

? 10.25 compression ratio, pump gas

? Custom made 26R deep airbox and mounting plate (stock Weber airbox reduced bhp by 7 on the dyno)

? Newly manufactured, CNC Weber head, street porting, from SAS Engineering, replacing original Federal Stromberg head. Final porting, finishing by Dave Vegher

? New Weber 151 40 DCOE?s with 32 mm chokes for street tractability. Contrary to popular wisdom that 45?s are needed to develop this level of horsepower, the 40?s develop substantial streetable horsepower and torque at lower rpms (with 7K redline). Not a WOT racing engine but rather quite tractable on the road throughout the rev range. Idles very smoothly and quietly below 1000 rpm. No throttle blips needed to keep it going.

Capacity is ~1700cc (precisely 1692cc)

? 1.625? intake valves, 1.375? exhaust (Manley). Stainless steel with hardchrome finish on stems

? Valve springs, US made by PSI industries

? Retainers US made VMW

? Keepers Generic 5/16? keepers

? Followers. Steel (Dave Bean)

? FF crank, square main bearing caps. Per Ford 77.6 mm stroke, shot peened and stress relieved, balanced SCCA/Scat

? Long FF Rods, 4.928? a/b centerline distance. ARP bolts

? Custom forged CP pistons, with special wrist pin heights, 3.2765? diameter, 3.2795? bore

? 10.25 compression ratio, pump gas

? Custom made 26R deep airbox and mounting plate (stock Weber airbox reduced bhp by 7 on the dyno)

? Newly manufactured, CNC Weber head, street porting, from SAS Engineering, replacing original Federal Stromberg head. Final porting, finishing by Dave Vegher

? New Weber 151 40 DCOE?s with 32 mm chokes for street tractability. Contrary to popular wisdom that 45?s are needed to develop this level of horsepower, the 40?s develop substantial streetable horsepower and torque at lower rpms (with 7K redline). Not a WOT racing engine but rather quite tractable on the road throughout the rev range. Idles very smoothly and quietly below 1000 rpm. No throttle blips needed to keep it going.

Capacity is ~1700cc (precisely 1692cc)

'69 Elan S4 SE

Street 181 BHP

Original owner

Street 181 BHP

Original owner

- 1owner69Elan

- Fourth Gear

- Posts: 897

- Joined: 16 Jun 2015

Sounds like a great engine. Thanks for sharing the specs. I saw on one post that you are at 33 degrees total ignition advance. What is your static advance and have you recurved the advance away from stock?

1963 Unicorn

1964 S1

1965 S2

1967 S3 SE DHC

Frankentwincam 26R

Seven S2 A

Seven S2 F

1964 S1

1965 S2

1967 S3 SE DHC

Frankentwincam 26R

Seven S2 A

Seven S2 F

- knockoffnut

- Third Gear

- Posts: 227

- Joined: 02 Sep 2011

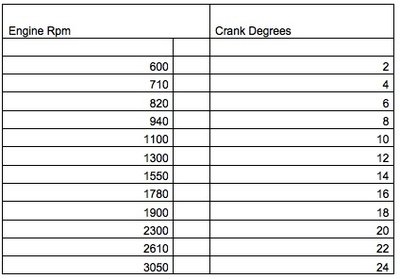

The car is using a Pertronix distributor #D1905. Using the default advance springs it came with.

With a static advance of 9 deg the total advance curve appears thusly:

500: 9

1000: 9

1500: 12

2000: 19

2500: 25

3000: 31

3500 and up: 33

Pertronix touts the advance curve as:

"Tailored advance curve for optimal performance and drivability."

I can say that there is no pinging (pinking) on pump gas, 91 octane (R+M)/2). The dyno results shown were on pump gas.

With a static advance of 9 deg the total advance curve appears thusly:

500: 9

1000: 9

1500: 12

2000: 19

2500: 25

3000: 31

3500 and up: 33

Pertronix touts the advance curve as:

"Tailored advance curve for optimal performance and drivability."

I can say that there is no pinging (pinking) on pump gas, 91 octane (R+M)/2). The dyno results shown were on pump gas.

'69 Elan S4 SE

Street 181 BHP

Original owner

Street 181 BHP

Original owner

- 1owner69Elan

- Fourth Gear

- Posts: 897

- Joined: 16 Jun 2015

I fitted the same Pertronix distributor to my engine, which has 10.5:1 compression now and it is much better than the original which Miles Wilkins in his book describes as unsuitable for modified engines. My engine is less modified than One Owners. I have the timing set about the same.

'65 S2 4844

- Davidb

- Fourth Gear

- Posts: 941

- Joined: 02 Jul 2009

Turns out I need to make a correction on the Pertronix advance curve for the D1905 distributor.

What I had posted earlier is from the chart that Pertronix publishes in their distributor instructions. However, upon further checking with Pertronix support, the curve is different for "British" distributors like the D1905:

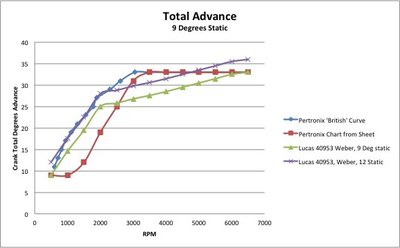

If you compare the "British" curve provided, it tracks closely to the original Lucas 40953 for Weber-standard (see Miles Wilkins) in the lower rpms. The various curves are shown below.

Note, what I don't quite understand is that using the "British" curve as provided, why don't I have a problem with pinging (pinking) on pump gas with CR of 10.3. As per Wilkins: "One thing is quite certain, the Big Valve must not have the the 40953 distributor fitted, otherwise severe pinking will occur due the engine being so over-advanced." The Big Valve ostensibly has a 10.5 CR vs my 10.3 - not that much difference to allow the aggressive advance curve I would think.

The whole issue of advance curves seems to be shrouded in misinformation and confusion. Something that Mile Wilkins tried to clarify. But, I still have questions.

In any event, I don't have pinking with the Pertronix D1905 (9 deg static) and I can't quarrel with the hp/torque results on pump gas.

What I had posted earlier is from the chart that Pertronix publishes in their distributor instructions. However, upon further checking with Pertronix support, the curve is different for "British" distributors like the D1905:

If you compare the "British" curve provided, it tracks closely to the original Lucas 40953 for Weber-standard (see Miles Wilkins) in the lower rpms. The various curves are shown below.

Note, what I don't quite understand is that using the "British" curve as provided, why don't I have a problem with pinging (pinking) on pump gas with CR of 10.3. As per Wilkins: "One thing is quite certain, the Big Valve must not have the the 40953 distributor fitted, otherwise severe pinking will occur due the engine being so over-advanced." The Big Valve ostensibly has a 10.5 CR vs my 10.3 - not that much difference to allow the aggressive advance curve I would think.

The whole issue of advance curves seems to be shrouded in misinformation and confusion. Something that Mile Wilkins tried to clarify. But, I still have questions.

In any event, I don't have pinking with the Pertronix D1905 (9 deg static) and I can't quarrel with the hp/torque results on pump gas.

'69 Elan S4 SE

Street 181 BHP

Original owner

Street 181 BHP

Original owner

- 1owner69Elan

- Fourth Gear

- Posts: 897

- Joined: 16 Jun 2015

This is a very interesting discussion (to me in any case) . There are many different factors which affect the onset of "pinking" or "ping" as it is variously called and this is the reason that I had asked. Detonation occurs first on hotspots in the chamber, typically formed at sharp edges. I have always spent a ridiculous amount of time during engine building, removing sharp edges, in the chamber by adding a nice radius to the valve cutouts in the piston tops, any sharp edges around the sparkplug hole, valve seat areas, and anywhere else I see a sharp edge in the chamber. This has the effect of delaying the onset of both knock and ping, especially on poor quality gas, and at higher compression. The net result is an engine which can sustain either more compression, or more advance, or both. It is a very complex situation and Mr. Wilkens has likely overstated the situation, in my experience. I have built engines which, after increasing the CR significantly, can still withstand MORE advance, than before the rebuild. I am sure that the varying amounts of alcohol (ethanol) content in different brands of gasoline also have an effect on this, similar to pure alcohol injection on turbo engines, so it is important to use the same gas in back to back tests. Your 33 degree advance caught my eye, and made me curious about the other mods you may have done, but also how soon the advance comes in at the lower revs, as I will be building a few twincams this year, including my Frankentwincam. My buddy has a 2.0L alloy twincam (LTC head on BDP block) built by a serious engine builder, set up on a dyno, and running 32 degrees of total advance at 8000RPM. I will likely try mine, when it is ready, at 30, 31, 32, 33, and 34 maximum advance and see what happens.

1963 Unicorn

1964 S1

1965 S2

1967 S3 SE DHC

Frankentwincam 26R

Seven S2 A

Seven S2 F

1964 S1

1965 S2

1967 S3 SE DHC

Frankentwincam 26R

Seven S2 A

Seven S2 F

- knockoffnut

- Third Gear

- Posts: 227

- Joined: 02 Sep 2011

Knockoffnut reminded me that my engine build also included Dave Vegher carefully removing sharp edges to avoid hot spots.

The other factor in my engine being able to run on pump gas but with substantial advance and reasonable CR is perhaps due to the modern alloy (LM 25 TF) used in the newly manufactured SAS head. Perhaps this new alloy provides better thermal efficiency than the original heads.

Another factor might be the precise CNC machining process and less porous casting producing a better overall combustion chamber shape and surface? Even if microscopically, not evident to the human eye.

The modern vs original aluminum alloys are certainly different. For example, these new heads allow running the cams without cam bearings. Dave also says when doing machining on the new heads that they are clearly "harder" and tend to wear out tooling much faster.

The other factor in my engine being able to run on pump gas but with substantial advance and reasonable CR is perhaps due to the modern alloy (LM 25 TF) used in the newly manufactured SAS head. Perhaps this new alloy provides better thermal efficiency than the original heads.

Another factor might be the precise CNC machining process and less porous casting producing a better overall combustion chamber shape and surface? Even if microscopically, not evident to the human eye.

The modern vs original aluminum alloys are certainly different. For example, these new heads allow running the cams without cam bearings. Dave also says when doing machining on the new heads that they are clearly "harder" and tend to wear out tooling much faster.

'69 Elan S4 SE

Street 181 BHP

Original owner

Street 181 BHP

Original owner

- 1owner69Elan

- Fourth Gear

- Posts: 897

- Joined: 16 Jun 2015

Knockoffnut, be interested to hear about your Frankentwincam build.

BTW, made a run over to Dave Vegher this morning in my Elan. We wanted to try a few different jets to see what, if anything, might change. After driving the car, as is, there really isn't much to complain about or improve on the engine. We did try a different idle jet, more just out of curiosity, but not a lot of difference and thus switched back to what I was running before (50F6). The tractability remains exemplary pulling cleanly and strongly throughout. Really fun to drive and as Dave noted - "easy to get into trouble with" - very tempting to get on it all the time at the risk of running afoul of the law.

Dave showed me around the shop. Lots of very interesting engine builds going on from twincams to BDA to Cosworth DFV's. One thing that was particularly interesting was a newly manufactured twincam head with the ability to run massive valve sizes. The combustion chamber footprint becomes more oval than circular to accommodate the larger valves. Displacement of the current build using this head will remain under 1600cc. From Jennings if I recall correctly. Also of interest was the use of special lightweight Carillo rods that run without bearings with a special coated wrist pin. Dramatic difference in overall outer dimensions and weight. Presumably faster throttle response and higher rpms.

BTW, made a run over to Dave Vegher this morning in my Elan. We wanted to try a few different jets to see what, if anything, might change. After driving the car, as is, there really isn't much to complain about or improve on the engine. We did try a different idle jet, more just out of curiosity, but not a lot of difference and thus switched back to what I was running before (50F6). The tractability remains exemplary pulling cleanly and strongly throughout. Really fun to drive and as Dave noted - "easy to get into trouble with" - very tempting to get on it all the time at the risk of running afoul of the law.

Dave showed me around the shop. Lots of very interesting engine builds going on from twincams to BDA to Cosworth DFV's. One thing that was particularly interesting was a newly manufactured twincam head with the ability to run massive valve sizes. The combustion chamber footprint becomes more oval than circular to accommodate the larger valves. Displacement of the current build using this head will remain under 1600cc. From Jennings if I recall correctly. Also of interest was the use of special lightweight Carillo rods that run without bearings with a special coated wrist pin. Dramatic difference in overall outer dimensions and weight. Presumably faster throttle response and higher rpms.

'69 Elan S4 SE

Street 181 BHP

Original owner

Street 181 BHP

Original owner

- 1owner69Elan

- Fourth Gear

- Posts: 897

- Joined: 16 Jun 2015

A CNC machined surface with a "tighter" alloy (harder, and less porous) will provide a nice smooth surface which means there wont be any tiny sharp edges which allow knock and ping to initiate. Knock and Ping behave just like water boiling. Heat up water in a nice smoothly polished stainless pot on the stove, and then just before, or just after it starts to boil throw in some salt, or sand and see how the sharp edges lower the energy of the reaction, enabling it to happen at lower levels... So I polish combustion chambers to a mirror finish, and smooth out any sharp edges with a generous radius.

Frankentwincam is an 1850cc LTC being built on a Cosworth BDP block, sleeved at 90mm bore. I had been planning to build a 2.0L with a 77.65mm stroke, until I came across a 72.75 steel crank, so I have decided to stay with 1850. It will run a vintage Lotus Twincam head with very big valves 1.70 intakes and 1.4 exhausts, radiused valve seats, opened up, polished ports, AE forged pistons, 72.75mm stroke steel wide journal crank, Steel rods, lightened steel flywheel (though I also have an alloy flywheel that fits), 45DCOE (Italian) Weber carbs, 440 cams, TTR big exhaust manifold. I will likely run about 11:1 compression, which require a bit of a dish in the piston tops. I will probably keep 5mm of the original piston top as a flat edge around the piston dish, though I am still debating the merits of this. I have a theory that running a flat top piston below the gasket surface instead of a dish should produce more horsepower with peak cylinder pressure occurring slightly sooner, so on slightly less advance (has anybody tried both?) Mating the LTC head and BDP block requires welding and significant machining of the block around the waterpump area in order to fit the LTC pump. The head must be welded to reduce the water ports in the head face where they come too close to the bores. Mine is a low budget, backyard build, so it won't likely ever see a dyno. It is only meant for fast road use in a lightweight Elan. I am aiming for a stock look, light weight and some extra torque and horsepower. As it is a road car it will get a wet sump, with baffles and windage tray. The BDP block has enough meat to machine it for the oil pickup configuration of the standard block. I have been talking with people who have experience with this type of engine build, in the hopes of not making too many mistakes the first time.

Frankentwincam is an 1850cc LTC being built on a Cosworth BDP block, sleeved at 90mm bore. I had been planning to build a 2.0L with a 77.65mm stroke, until I came across a 72.75 steel crank, so I have decided to stay with 1850. It will run a vintage Lotus Twincam head with very big valves 1.70 intakes and 1.4 exhausts, radiused valve seats, opened up, polished ports, AE forged pistons, 72.75mm stroke steel wide journal crank, Steel rods, lightened steel flywheel (though I also have an alloy flywheel that fits), 45DCOE (Italian) Weber carbs, 440 cams, TTR big exhaust manifold. I will likely run about 11:1 compression, which require a bit of a dish in the piston tops. I will probably keep 5mm of the original piston top as a flat edge around the piston dish, though I am still debating the merits of this. I have a theory that running a flat top piston below the gasket surface instead of a dish should produce more horsepower with peak cylinder pressure occurring slightly sooner, so on slightly less advance (has anybody tried both?) Mating the LTC head and BDP block requires welding and significant machining of the block around the waterpump area in order to fit the LTC pump. The head must be welded to reduce the water ports in the head face where they come too close to the bores. Mine is a low budget, backyard build, so it won't likely ever see a dyno. It is only meant for fast road use in a lightweight Elan. I am aiming for a stock look, light weight and some extra torque and horsepower. As it is a road car it will get a wet sump, with baffles and windage tray. The BDP block has enough meat to machine it for the oil pickup configuration of the standard block. I have been talking with people who have experience with this type of engine build, in the hopes of not making too many mistakes the first time.

1963 Unicorn

1964 S1

1965 S2

1967 S3 SE DHC

Frankentwincam 26R

Seven S2 A

Seven S2 F

1964 S1

1965 S2

1967 S3 SE DHC

Frankentwincam 26R

Seven S2 A

Seven S2 F

- knockoffnut

- Third Gear

- Posts: 227

- Joined: 02 Sep 2011

22 posts

• Page 1 of 2 • 1, 2

Total Online:

Users browsing this forum: crannyr and 16 guests