Cosworth YB Turbo Into Elan

elansprint71 wrote:Steve- just a quick check; you are not Keith Frank, or a very close relative, are you?

No 'fence 'tended...

Which Keith Frank are you referring to?

- stevebroad

- Fourth Gear

- Posts: 917

- Joined: 08 Mar 2004

abstamaria wrote:What a project! You are a brave (and creative) man, Steve.

Andy

Thanks. However, brave is a very close friend of stupid

- stevebroad

- Fourth Gear

- Posts: 917

- Joined: 08 Mar 2004

The calculations have been done and it is as we suspected. The torsional rigidity of the chassis is, not to put too fine a point on it, crap.

Right, how to stiffen things up?

The body, contrary to what I always thought, does add significantly to the torsional rigidity of the chassis, so this is where I plan to attack the problem. I have dropped the idea of widening the central section of the chassis as this just makes more problems.

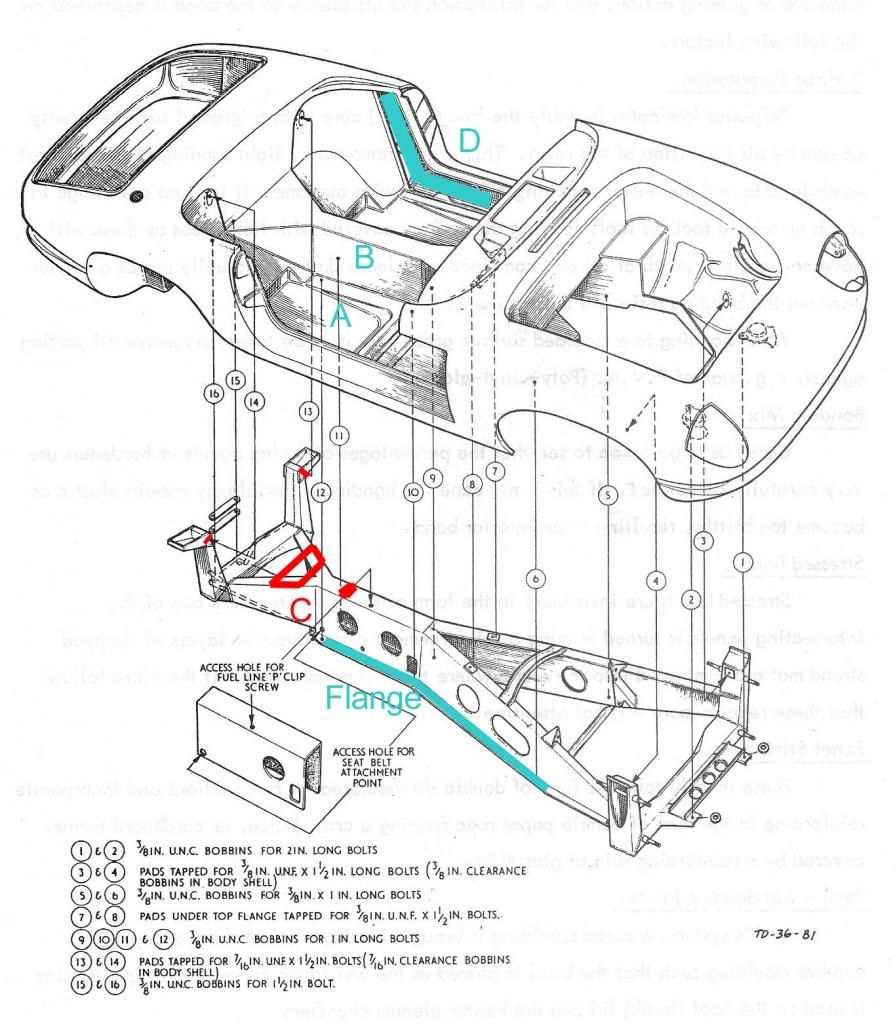

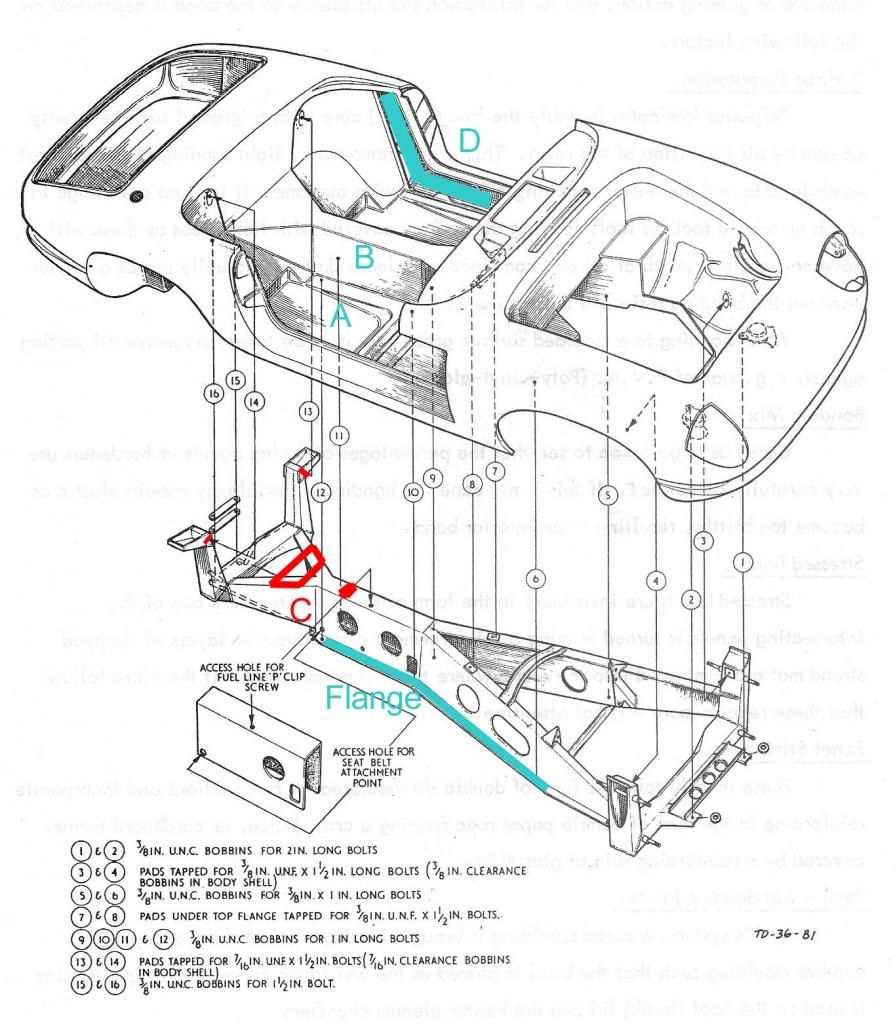

My plan is to stiffen up the floor A and the box section B covering the chassis with carbon fibre. I will glue the carbon fibre panels that surround the door opening D to the existing body and join the floor carbon fibre to them.

I will then bolt the body to the chassis with a lot more fasteners than the standard 16, especially in the cental box area. I will sandwich the body between the chassis flange and a steel strip in order to add axtra stiffness.

The roll bar fits to the body fasterners 13 and 14 and bolts to the chassis at the locations in red C

I will also look to add vertical stiffening between the body's central box section and the outer body panels wherever possible.

All extra weight, I know, but sometimes there is no choice

Right, how to stiffen things up?

The body, contrary to what I always thought, does add significantly to the torsional rigidity of the chassis, so this is where I plan to attack the problem. I have dropped the idea of widening the central section of the chassis as this just makes more problems.

My plan is to stiffen up the floor A and the box section B covering the chassis with carbon fibre. I will glue the carbon fibre panels that surround the door opening D to the existing body and join the floor carbon fibre to them.

I will then bolt the body to the chassis with a lot more fasteners than the standard 16, especially in the cental box area. I will sandwich the body between the chassis flange and a steel strip in order to add axtra stiffness.

The roll bar fits to the body fasterners 13 and 14 and bolts to the chassis at the locations in red C

I will also look to add vertical stiffening between the body's central box section and the outer body panels wherever possible.

All extra weight, I know, but sometimes there is no choice

- stevebroad

- Fourth Gear

- Posts: 917

- Joined: 08 Mar 2004

Not much happening on car as waiting for welded to be repaired so I can repair engine mount bracket that I managed to cut through whilst removing the ARB bracket!

In order to do something I have continued development work on the wheelie bar. Assembled it dry (nothing glued) and it seems to fit. I won't know how stiff or twisty it is until I have glued the rod end holders into the CF tubes, tightened the rod end nuts and secured the central support firmly to the tubes.

In order to do something I have continued development work on the wheelie bar. Assembled it dry (nothing glued) and it seems to fit. I won't know how stiff or twisty it is until I have glued the rod end holders into the CF tubes, tightened the rod end nuts and secured the central support firmly to the tubes.

Last edited by stevebroad on Mon Jan 26, 2015 12:50 pm, edited 1 time in total.

- stevebroad

- Fourth Gear

- Posts: 917

- Joined: 08 Mar 2004

I've just remembered that on the 9th Jan I posted this:

What I don't quite get is why you have kept any vestige of the original Elan folded-sheet chassis. They cost less than ?15 when new and, by modern race-chassis standards, are about as torsionally-rigid as a bowl of custard... without the bowl (and that's before you put the extra holes in). Back in the day racing-folks were making them stronger, rather than putting more holes in them.

I'd be interested to hear your reasoning on this aspect.

So having lightened (and thereby weakened the chassis), you are now beefing it and the body up, thereby removing lightness! Any comment from Graham Hathaway on the torsional tests?

I've also just remembered that I used to be a Mechanical Engineer, at one time specialising in structural frameworks.

What I don't quite get is why you have kept any vestige of the original Elan folded-sheet chassis. They cost less than ?15 when new and, by modern race-chassis standards, are about as torsionally-rigid as a bowl of custard... without the bowl (and that's before you put the extra holes in). Back in the day racing-folks were making them stronger, rather than putting more holes in them.

I'd be interested to hear your reasoning on this aspect.

So having lightened (and thereby weakened the chassis), you are now beefing it and the body up, thereby removing lightness! Any comment from Graham Hathaway on the torsional tests?

I've also just remembered that I used to be a Mechanical Engineer, at one time specialising in structural frameworks.

Cheers,

Pete.

http://www.petetaylor.org.uk

LOTUS ELAN flickr GROUP: https://www.flickr.com/groups/2515899@N20

flickr: http://www.flickr.com/photos/16096573@N02/sets/72157624226380576/

https://www.flickr.com/photos/16096573@N02/

Pete.

http://www.petetaylor.org.uk

LOTUS ELAN flickr GROUP: https://www.flickr.com/groups/2515899@N20

flickr: http://www.flickr.com/photos/16096573@N02/sets/72157624226380576/

https://www.flickr.com/photos/16096573@N02/

-

elansprint71 - Coveted Fifth Gear

- Posts: 4438

- Joined: 16 Sep 2003

The lightening of the chassis was done with guidance from Graham. The chassis was modifed to 26R spec plus (done by Graham) and is stiffer than a 26R chassis but, as you say, that isn't saying much. The floppy strip that the body bolts to has little bearing on chassis twist but that is now a lot stiffer with the swaged/flanged holes in it. The lightening of the front and rear uprights has no effect on the tortional stiffness.

Therefore, in my (and Graham's) opinion, the lightening undertaken has not adversly affected chassis stiffness.

The 26R chassis twists like Chubby Checker, so the planned body stiffening should reduce that substantionally.

Therefore, in my (and Graham's) opinion, the lightening undertaken has not adversly affected chassis stiffness.

The 26R chassis twists like Chubby Checker, so the planned body stiffening should reduce that substantionally.

Last edited by stevebroad on Tue Jan 27, 2015 6:15 pm, edited 1 time in total.

- stevebroad

- Fourth Gear

- Posts: 917

- Joined: 08 Mar 2004

Oops, Captain Cockup has just flown in.

Woke up at 1.30am last night. Lying there mulling things over and I realised that I had cocked upon the design of the wheelie bar. Basic structural geometry taught in primary schools. 3 sided structures stiff, 4 sided not. With all joints flexible and the design 4 sided it will flop about!

Checked this morning and, yes, it is floppy. What an idiot!

Just been to Heathrow to pick up sister-in-law and family so had thinking time and have worked out what to do. Basically, the two bottom rails need to be rigidly fixed to the wheel hub and I have designed this modification in my head (maybe not the best place bearing in mind what I have just done!).

Woke up at 1.30am last night. Lying there mulling things over and I realised that I had cocked upon the design of the wheelie bar. Basic structural geometry taught in primary schools. 3 sided structures stiff, 4 sided not. With all joints flexible and the design 4 sided it will flop about!

Checked this morning and, yes, it is floppy. What an idiot!

Just been to Heathrow to pick up sister-in-law and family so had thinking time and have worked out what to do. Basically, the two bottom rails need to be rigidly fixed to the wheel hub and I have designed this modification in my head (maybe not the best place bearing in mind what I have just done!).

- stevebroad

- Fourth Gear

- Posts: 917

- Joined: 08 Mar 2004

Bar, including all fixings, weighs in at 3.8kg. However, once I have modified it so it will actually work it will probably be around 4kg.

- stevebroad

- Fourth Gear

- Posts: 917

- Joined: 08 Mar 2004

Is this a troll thread?

Just asking?

If so, pass me the donkey's ears, I don't pay too much attention round here these days.

Just asking?

If so, pass me the donkey's ears, I don't pay too much attention round here these days.

Cheers,

Pete.

http://www.petetaylor.org.uk

LOTUS ELAN flickr GROUP: https://www.flickr.com/groups/2515899@N20

flickr: http://www.flickr.com/photos/16096573@N02/sets/72157624226380576/

https://www.flickr.com/photos/16096573@N02/

Pete.

http://www.petetaylor.org.uk

LOTUS ELAN flickr GROUP: https://www.flickr.com/groups/2515899@N20

flickr: http://www.flickr.com/photos/16096573@N02/sets/72157624226380576/

https://www.flickr.com/photos/16096573@N02/

-

elansprint71 - Coveted Fifth Gear

- Posts: 4438

- Joined: 16 Sep 2003

elansprint71 wrote:Is this a troll thread?

Just asking?

If so, pass me the donkey's ears, I don't pay too much attention round here these days.

A troll thread?

However, I can sort of see why you would think this.

- stevebroad

- Fourth Gear

- Posts: 917

- Joined: 08 Mar 2004

OK, Don't fancy cutting body about in order to fit carbon fibre panels in an attempt to stiffen everything up, so looking at fitting a full roll cage instead. I know it will weigh around 40kg, which hurts, but I will have to live with that.

However, has anyone any idea how much a Safery Devices full roll cage (welded not bolted) would improve the torsional stiffness by? I know, how long is a piece of string?, but some research may have been done.

Steve "me, a troll?" Broad

However, has anyone any idea how much a Safery Devices full roll cage (welded not bolted) would improve the torsional stiffness by? I know, how long is a piece of string?, but some research may have been done.

Steve "me, a troll?" Broad

- stevebroad

- Fourth Gear

- Posts: 917

- Joined: 08 Mar 2004

Steve,

Since nobody has responded, I'll attempt an answer. The Safety Devices roll cage you reference is designed to meet strict F.I.A. vintage race rules. The number of attachment points are restricted by the rules. To add rigidity to the structure, additional braces and attachment points are needed. Like attachment to the door sill latices and additional braces from the tunnel up to the rear strut towers. Forward braces to the front turrets (and across) would also help. As far as adding carbon fiber for strength, I would suggest adding several layers of carbon to the fiberglass body, tunnel section, along with additional bobbins glassed (carbon fiber) in along the bottom to bolt to the chassis. Some additional carbon and bobbins on top of the tunnel also.

Vic

Since nobody has responded, I'll attempt an answer. The Safety Devices roll cage you reference is designed to meet strict F.I.A. vintage race rules. The number of attachment points are restricted by the rules. To add rigidity to the structure, additional braces and attachment points are needed. Like attachment to the door sill latices and additional braces from the tunnel up to the rear strut towers. Forward braces to the front turrets (and across) would also help. As far as adding carbon fiber for strength, I would suggest adding several layers of carbon to the fiberglass body, tunnel section, along with additional bobbins glassed (carbon fiber) in along the bottom to bolt to the chassis. Some additional carbon and bobbins on top of the tunnel also.

Vic

- Vic

- Second Gear

- Posts: 58

- Joined: 12 Dec 2012

Hi Vic

Thanks for your thoughts.

With the body's weakest point coinsiding with the chassis' weakest point, the body adds very little to the tortional stiffness so we are going to ignore it. The sketch below is just a work in progress and we won't be able to harden up on the design until engine and body are back in/on the chassis. We have added our own thoughts (edged in red) to an existing sketch gabbed from the web. The door bars will be the only tubes not welded, so once fitted the body will be on for good.

Thanks for your thoughts.

With the body's weakest point coinsiding with the chassis' weakest point, the body adds very little to the tortional stiffness so we are going to ignore it. The sketch below is just a work in progress and we won't be able to harden up on the design until engine and body are back in/on the chassis. We have added our own thoughts (edged in red) to an existing sketch gabbed from the web. The door bars will be the only tubes not welded, so once fitted the body will be on for good.

- stevebroad

- Fourth Gear

- Posts: 917

- Joined: 08 Mar 2004

Total Online:

Users browsing this forum: No registered users and 3 guests