Machine tools for maintaining your cars?

Galwaylotus wrote:GrUmPyBoDgEr wrote:Incredibly to my amazement they now charge for Air at filling stations in GB!!!!!

I'm actually surprised that garages haven't always charged for compressed air. It's one of the most expensive forms of energy!!

John

Beware of the Illuminati

Editor: On Sunday morning, February 8th 2015, Derek "John" Pelly AKA GrumpyBodger passed away genuinely peacefully at Weston Hospicecare, Weston Super Mare. He will be missed.

Editor: On Sunday morning, February 8th 2015, Derek "John" Pelly AKA GrumpyBodger passed away genuinely peacefully at Weston Hospicecare, Weston Super Mare. He will be missed.

-

GrUmPyBoDgEr - Coveted Fifth Gear

- Posts: 3062

- Joined: 29 Oct 2004

paddy wrote:So who's got an air compressor in their workshop?

Well I have, I would not be without one, just so useful, blowing tyres, cleaning filters on wife's vacuum cleaner, cleaning carb jets, cleaning parts, cleaning engine (paraffin spray gun) blowing out the cars etc etc.

Mine is not massive but has V twin cylinders and a 1hp motor, I've sprayed wheels and other small parts and could probably spray a car if I sprayed one panel at a time.

My lathe is a little small but useful for turning small jobs, I also used to have a Myford 7 but to my regret did not bring it with me when I relocated countries.

Brian

64 S2 Roadster

72 Sprint FHC

64 S2 Roadster

72 Sprint FHC

-

types26/36 - Coveted Fifth Gear

- Posts: 3873

- Joined: 11 Sep 2003

Thanks for the responses.

I put off buying a bench press for ages, but now I wonder how I managed without. I imagine the same would be true of the compressor. I had already looked at what spec you need to run the 1/2" impact wrench and seen that the various DIY products don't really do the job, so it starts to get expensive

Then again, there's no bigger waste of time and money than cheap tools.

Paddy

I put off buying a bench press for ages, but now I wonder how I managed without. I imagine the same would be true of the compressor. I had already looked at what spec you need to run the 1/2" impact wrench and seen that the various DIY products don't really do the job, so it starts to get expensive

Then again, there's no bigger waste of time and money than cheap tools.

Paddy

1963 Elan S1

-

paddy - Coveted Fifth Gear

- Posts: 1196

- Joined: 27 Oct 2008

alexblack13 wrote:The flat belt drive system brings back memories.. When I first started a few of our machines were steam driven. And I am not kidding either. I was with the company for a few year before we removed it.. It just went in the scrap bin...

I see the machine you have, which is a beut by the way, has an idler pulley? does it have the mechanism for switching the belt from 'Idle to drive pulley?

Try getting that past the HSE nowadays....

I some how don't think so!

I had a nice horizontal mill with a great universal add on head and sold it some time ago. Another big mistake! But I was running out of room for working on the bikes and Scoots. (Just bought a very rare Vespa Douglas)

OH well..

Alex...

Yes it has the belt move mechanism from idle to GO. You can see it on this picture on my own website on the link above. http://www.datahighways.net/support/top ... orum_id=29

For which this is a miniature version of the photo.

Does 'elf & safetea apply in ones own personal workshop?

Bit pointless worrying about getting caught in belt drives, when (if you don't know what you are doing) you can get your tie or fingers caught between the cutting tool & the workpiece.

Bill Williams

36/6725 S3 Coupe OGU108E Yellow over Black.

36/6725 S3 Coupe OGU108E Yellow over Black.

- billwill

- Coveted Fifth Gear

- Posts: 5062

- Joined: 19 Apr 2008

billwill wrote:

Bit pointless worrying about getting caught in belt drives, when (if you don't know what you are doing) you can get your tie or fingers caught between the cutting tool & the workpiece.

Have you got a very posh workshop then Bill?

Stuart Holding

Thame UK / Alpe D'Huez France

69 S4 FHC

Honda GoldWing 1800

Honda CBX1000

Kawasaki H1 500

Yamaha XS2

Thame UK / Alpe D'Huez France

69 S4 FHC

Honda GoldWing 1800

Honda CBX1000

Kawasaki H1 500

Yamaha XS2

- 69S4

- Coveted Fifth Gear

- Posts: 1347

- Joined: 23 Sep 2004

Paddy:

I'd have to say the first piece of "machinery" I ever bought was a compressor. Don't know that it's actually a "machine tool", so perhaps we're straying off topic here, but I'd still put it at the top of the list. As others noted, you're forever blowing things off with it, and filling tires. It also opens up lots of other options that might otherwise not be a possibility.

In the "small tools" arena, the air-wratchet and impact wrench are lifesavers, as I couldn't have removed old suspension bushings with such a simple contraption without it (elan-f15/removing-year-old-front-suspension-bushings-with-photos-t23684.html).

For any grinding work, a pneumatic disc grinder has also been really handy, while a die grinder has allowed me to do surprisingly precise work in relatively small spaces. While you could probably do much the same with electric powered tools, the pneumatics are lighter and more nimble, in my experience. Finally, you've got options for other solutions in the future. I (probably impulsively) bought a blast cabinet that will make life much easier for me as I strip down and refinish suspension and other bits on the car. Hard to know if I'll use it after this rebuild, but the point is that I have the option because of the air supply I already own. I also plan to make my own soda blaster (http://www.aircooledtech.com/tools-on-t ... a_blaster/) for cleaning my Weber carb bodies, and again, couldn't do that without the air.

Regarding the compressor itself, I opted for something that I could use to spray a car if I wanted to (done a couple in the past, so maybe I'll be just that crazy again someday). I didn't want it running constantly, and was glad for that choice when I spent a day grinding on the frame welds a few weeks back. It's loud when it's on, but it's not on for more than a couple minutes, and then can run many tools for 10 minutes straight before needing to recharge.

I opted for an upright (major space saving design) 80gal, single stage model from Campbell Hausfeld. It delivers 135psi, and about 16CFM @ 90psi. In short, plenty of air for anything I need. It was something like $900 several years ago, and looks something like this:

I actually started this thread looking for advice on machine tools, specifically a combo lathe/mill vs. separate units. Here I am, taking the "buy big" approach, which may not be right for you. If you're mostly about pumping tires, dusting things off, and perhaps running an air wratchet, you can probably go much lighter, smaller and cheaper, which is good. The downside is that you'll probably run into a situation where your compressor won't be able to do something you want, and it'll generally run more frequently and be much louder. I say this assuming you just want info to help make a decision. We all know when our compressor is running, but some of them have a higher pitched, dental drill hammering, while the bigger compressors sound more like a motor running, at a lower pitch. This last item is something I didn't think about, but was brought home when working with a friends small compressor for the day. Bit of a headache by the end. Made me love my decision that much more.

I'm rambling here, so my last comment is that I just bought a mill/lathe combo. I can easily see regretting it when it's sat for years and I only used it twice . I've never felt that way about the compressor, even during the years when I only ran it every 6 months to blow dust off things. Every Lotus owner should have one, and big is good, but expensive, but only done once. Oh, and the upright takes barely more floor space than any most other models, actually.

. I've never felt that way about the compressor, even during the years when I only ran it every 6 months to blow dust off things. Every Lotus owner should have one, and big is good, but expensive, but only done once. Oh, and the upright takes barely more floor space than any most other models, actually.

Hope that helps,

Dave

P.S. I've got to start being more brief in my responses, don't I.

I'd have to say the first piece of "machinery" I ever bought was a compressor. Don't know that it's actually a "machine tool", so perhaps we're straying off topic here, but I'd still put it at the top of the list. As others noted, you're forever blowing things off with it, and filling tires. It also opens up lots of other options that might otherwise not be a possibility.

In the "small tools" arena, the air-wratchet and impact wrench are lifesavers, as I couldn't have removed old suspension bushings with such a simple contraption without it (elan-f15/removing-year-old-front-suspension-bushings-with-photos-t23684.html).

For any grinding work, a pneumatic disc grinder has also been really handy, while a die grinder has allowed me to do surprisingly precise work in relatively small spaces. While you could probably do much the same with electric powered tools, the pneumatics are lighter and more nimble, in my experience. Finally, you've got options for other solutions in the future. I (probably impulsively) bought a blast cabinet that will make life much easier for me as I strip down and refinish suspension and other bits on the car. Hard to know if I'll use it after this rebuild, but the point is that I have the option because of the air supply I already own. I also plan to make my own soda blaster (http://www.aircooledtech.com/tools-on-t ... a_blaster/) for cleaning my Weber carb bodies, and again, couldn't do that without the air.

Regarding the compressor itself, I opted for something that I could use to spray a car if I wanted to (done a couple in the past, so maybe I'll be just that crazy again someday). I didn't want it running constantly, and was glad for that choice when I spent a day grinding on the frame welds a few weeks back. It's loud when it's on, but it's not on for more than a couple minutes, and then can run many tools for 10 minutes straight before needing to recharge.

I opted for an upright (major space saving design) 80gal, single stage model from Campbell Hausfeld. It delivers 135psi, and about 16CFM @ 90psi. In short, plenty of air for anything I need. It was something like $900 several years ago, and looks something like this:

I actually started this thread looking for advice on machine tools, specifically a combo lathe/mill vs. separate units. Here I am, taking the "buy big" approach, which may not be right for you. If you're mostly about pumping tires, dusting things off, and perhaps running an air wratchet, you can probably go much lighter, smaller and cheaper, which is good. The downside is that you'll probably run into a situation where your compressor won't be able to do something you want, and it'll generally run more frequently and be much louder. I say this assuming you just want info to help make a decision. We all know when our compressor is running, but some of them have a higher pitched, dental drill hammering, while the bigger compressors sound more like a motor running, at a lower pitch. This last item is something I didn't think about, but was brought home when working with a friends small compressor for the day. Bit of a headache by the end. Made me love my decision that much more.

I'm rambling here, so my last comment is that I just bought a mill/lathe combo. I can easily see regretting it when it's sat for years and I only used it twice

Hope that helps,

Dave

P.S. I've got to start being more brief in my responses, don't I.

Dave

'66 Elan S2 - 26/4378

'66 Elan S2 - 26/4378

-

bilcoh - Second Gear

- Posts: 164

- Joined: 10 Jul 2011

69S4 wrote:billwill wrote:

Bit pointless worrying about getting caught in belt drives, when (if you don't know what you are doing) you can get your tie or fingers caught between the cutting tool & the workpiece.

Have you got a very posh workshop then Bill?

Nah, wot I meant was only someone who did not know what they are doing would wear a tie in a workshop.

Bill Williams

36/6725 S3 Coupe OGU108E Yellow over Black.

36/6725 S3 Coupe OGU108E Yellow over Black.

- billwill

- Coveted Fifth Gear

- Posts: 5062

- Joined: 19 Apr 2008

I have the same compressor as Dave. It took me buying 2 others that were insufficient in the volume of air produced to realize each had been a mistake. This one will run a HVLP spray gun and never run out of air. Will also run a DA sander and any other air tool I have in the garage without complaint. I have had this one for about 10 years and have never been sorry. And I use the crap out of it. My only complaint is the noise it generates, so, while I am in the process of building a new garage, I have built a separate closet, fully insulated, with outside venting for fresh air and cooling. A rotary compressor would have been much quieter, but was almost 4 times the cost.

I originally had a 9 inch Atlas lathe, which I found too small to do the things I wanted to do. Sold it for what I paid for it 20 years before, and purchased a 13 inch Asian unit. Not the best in the world, but, if careful, I can hold a tight tolerance. And, there have been times when I wish I had bought the 14 inch version. Four inch stock is a bit of a pain to work with, only having a 6 inch chuck. I also purchased what is known as a mill/drill. Have made lots of things with this unit, but it is also a pain to use, because you have to move the head rather than the table when using different tooling. Should have spent more and purchased what was correct for the things I make.

I also have a Mig, Tig, gas and buzz box arc welders. Each has its own use. I love the Tig the most, and if I had to have only one, that would be the one.

Another tool I use almost every time I am in the garage, is the 6x48 belt sander with a 12 inch disc. The one that should be completely worn out is the horizontal metal cutting band saw.

As for sitting idle, almost every tool, with exception of one or more of welders is used every month. Today, I will use the Mig and the band saw to fabricate posts for the new stairs railing, leading down from the deck over the new garage to ground level.

Rob Walker

26-4889

I originally had a 9 inch Atlas lathe, which I found too small to do the things I wanted to do. Sold it for what I paid for it 20 years before, and purchased a 13 inch Asian unit. Not the best in the world, but, if careful, I can hold a tight tolerance. And, there have been times when I wish I had bought the 14 inch version. Four inch stock is a bit of a pain to work with, only having a 6 inch chuck. I also purchased what is known as a mill/drill. Have made lots of things with this unit, but it is also a pain to use, because you have to move the head rather than the table when using different tooling. Should have spent more and purchased what was correct for the things I make.

I also have a Mig, Tig, gas and buzz box arc welders. Each has its own use. I love the Tig the most, and if I had to have only one, that would be the one.

Another tool I use almost every time I am in the garage, is the 6x48 belt sander with a 12 inch disc. The one that should be completely worn out is the horizontal metal cutting band saw.

As for sitting idle, almost every tool, with exception of one or more of welders is used every month. Today, I will use the Mig and the band saw to fabricate posts for the new stairs railing, leading down from the deck over the new garage to ground level.

Rob Walker

26-4889

Rob Walker

26-4889

50-0315N

1964 Sabra GT

1964 Elva Mk4T Coupe (awaiting restoration)

1965 Ford Falcon Ranchero, 302,AOD,9",rack and pinion,disc,etc,etc,etc

1954 Nash Healey LeMans Coupe

Owning a Lotus will get you off the couch

26-4889

50-0315N

1964 Sabra GT

1964 Elva Mk4T Coupe (awaiting restoration)

1965 Ford Falcon Ranchero, 302,AOD,9",rack and pinion,disc,etc,etc,etc

1954 Nash Healey LeMans Coupe

Owning a Lotus will get you off the couch

- prezoom

- Coveted Fifth Gear

- Posts: 1337

- Joined: 16 Mar 2009

Dave/Rob,

Thanks for the detailed and considered responses. My instinct is definitely to buy it once only and get the right thing, but 80 gal. is *way* bigger than what I was looking at. PSI and CFM numbers are similar though.

I have 2 electric impact wrenches - one 1/2" and one 3/4", and the large one in particular will easily loosen or destroy anything you point it at. The main problem with it is the bulk of it - on occasions I've had to strip away a number of parts to get access, when an air wrench would fit quite comfortably.

Thanks again for the input.

Paddy

Thanks for the detailed and considered responses. My instinct is definitely to buy it once only and get the right thing, but 80 gal. is *way* bigger than what I was looking at. PSI and CFM numbers are similar though.

I have 2 electric impact wrenches - one 1/2" and one 3/4", and the large one in particular will easily loosen or destroy anything you point it at. The main problem with it is the bulk of it - on occasions I've had to strip away a number of parts to get access, when an air wrench would fit quite comfortably.

Thanks again for the input.

Paddy

1963 Elan S1

-

paddy - Coveted Fifth Gear

- Posts: 1196

- Joined: 27 Oct 2008

69S4 wrote:Have you got a very posh workshop then Bill?

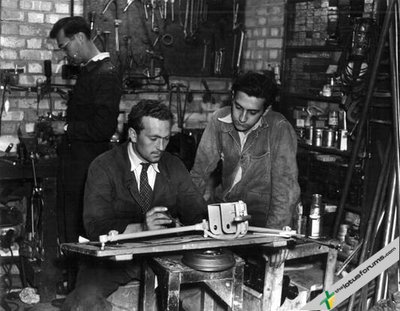

Well back in the day when Bill's belt driven lathe was the cutting edge of innovation the drivers and mechanics wore ties and white overhauls.....maybe not a white gloved Mclaren F1 technical centre of todays F1 but very smart....

Brian

64 S2 Roadster

72 Sprint FHC

64 S2 Roadster

72 Sprint FHC

-

types26/36 - Coveted Fifth Gear

- Posts: 3873

- Joined: 11 Sep 2003

paddy wrote:Brian, which one's you?

Ah....yes Paddy...you would not believe me .....I volunteered for this program...

http://www.telegraph.co.uk/health/healt ... youth.html

Brian

64 S2 Roadster

72 Sprint FHC

64 S2 Roadster

72 Sprint FHC

-

types26/36 - Coveted Fifth Gear

- Posts: 3873

- Joined: 11 Sep 2003

I was going to reply to Bill's post about ties by saying, while quickly running for cover,

"You mean like this guy?"

Then I canceled the post for fear of charges of blasphemy and being excommunicated. Truthfully, I just couldn't find any of the photos of guys assembling twinks in the 60's wearing ties under their machinist coats, though I know they exist.

Paddy, 80 gal is not expressly required. I think it just means you're likely to get more time between motor runs to refill the tank. You can get away with less for sure. Glad it's helpful, and I think you're exactly understanding the benefit of air tools, in that they're lighter and smaller. Easier access, as well as easier on you. And, I dare say, more durable tools? I've got a disc grinder that's at least 30 years old and buzzes along just fine. Many more electric tools have died offer sooner than that.

Good luck. Got a link to the unit you're considering?

Dave

"You mean like this guy?"

Then I canceled the post for fear of charges of blasphemy and being excommunicated. Truthfully, I just couldn't find any of the photos of guys assembling twinks in the 60's wearing ties under their machinist coats, though I know they exist.

Paddy, 80 gal is not expressly required. I think it just means you're likely to get more time between motor runs to refill the tank. You can get away with less for sure. Glad it's helpful, and I think you're exactly understanding the benefit of air tools, in that they're lighter and smaller. Easier access, as well as easier on you. And, I dare say, more durable tools? I've got a disc grinder that's at least 30 years old and buzzes along just fine. Many more electric tools have died offer sooner than that.

Good luck. Got a link to the unit you're considering?

Dave

Dave

'66 Elan S2 - 26/4378

'66 Elan S2 - 26/4378

-

bilcoh - Second Gear

- Posts: 164

- Joined: 10 Jul 2011

bilcoh wrote:I just couldn't find any of the photos of guys assembling twinks in the 60's wearing ties under their machinist coats, though I know they exist.

Not the right twincam, but will this do?

http://www.lotusespritworld.com/images/ ... g-made.jpg

bilcoh wrote:Got a link to the unit you're considering?

Maybe something like this:

http://www.justoffbase.co.uk/Compressor ... y-SAC10030

Paddy

1963 Elan S1

-

paddy - Coveted Fifth Gear

- Posts: 1196

- Joined: 27 Oct 2008

paddy wrote:Not the right twincam, but will this do?

http://www.lotusespritworld.com/images/ ... g-made.jpg

Maybe something like this:

http://www.justoffbase.co.uk/Compressor ... y-SAC10030

Paddy

Pretty close on the twin cams, Paddy. I think I'm envisioning some old stock BMC footage, perhaps, but basically the same thing. Are those 907 motors?

As for the compressor, my dad has something much older, but similar design. Not sure if its the type that would have have the higher-pitch hammering sound or not, nor if that matters to you. Anyone know if it's the direct drive style pump that creates the greater noise vs. a flywheel driven unit?

Also, perhaps others here could weigh in on which tools you could reasonably run with that, and which would lose power for lack of air volume. Either way, the addition of compressed air in any form will improve your garage life experience, I'm sure. Looking at prices to get to a vertical unit, you really do start paying premiums just for that. This one is basically the same unit, but in vertical form, for GBP 130 more (forgive me, but I don't have the fancy symbol for Sterling. OH WAIT! Quid! It's 130 quid more. Brilliant.) Not sure how Sealey stacks up as a brand, but here's an alternative in the US for about 400 quid.

http://www.amazon.com/Powermate-PLA3706 ... B002MKP5PG

And you're already committing the floor space. You see where I'm trying to take you, right?

Seriously, though, best of luck with the decision,

Dave

Dave

'66 Elan S2 - 26/4378

'66 Elan S2 - 26/4378

-

bilcoh - Second Gear

- Posts: 164

- Joined: 10 Jul 2011

Total Online:

Users browsing this forum: No registered users and 4 guests